展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

BEST DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

All New BESDIA® Ceramic Fiber Stone use the special ceramic fibers combinated with the unique bonding material and manufacturing process. Compare to other brand :

1. Our improvements in production processes give better tensile strength to the stones, hence fewer breakages.

2. A polishing efficiency increase of 10% to 20% has been achieved.

3. Durability under the same working conditions has been increased by 10% to 30%.

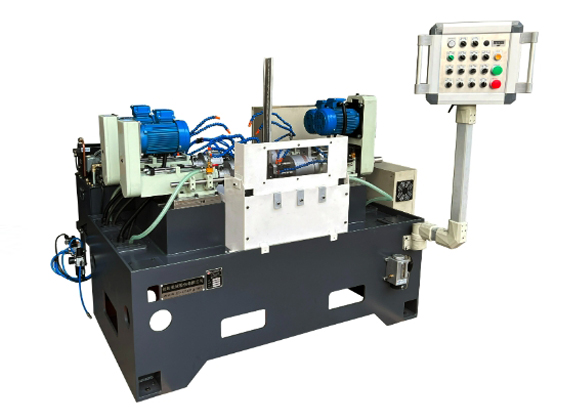

YI CHANG MACHINERY CO., LTD.

製品の説明 :

Linking a made horizontal Unith drilling machine and tapping machine with a hydraulic sliding table, assemble with an automatic loading and unloading system, enables rapid completion of drilling, tapping, and double-sided chamfering tasks.

This setup saves labor and allows precise control of relative positions.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!

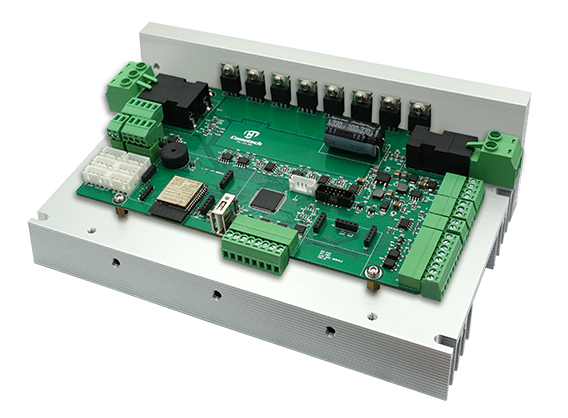

COMETECH TESTING MACHINES CO., LTD.

製品の説明 :

Besides adjusting the motor speed, users can set up detailed motor-related data settings with our C2 series driver. Its multifunctional integrated design is the main feature and advantage for saving costs and reducing external components.

Users can connect directly to the dedicated software for easy parameter tuning and configuration with the built-in Wi-Fi module. An over-the-air firmware update without assembling the driver from devices can improve maintenance efficiency and convenience.

Moreover, the driver features a modular expansion design that allows flexible extensions of communication formats, wireless screen modules, and more to meet various user needs.

※Specification

-Rated Voltage: DC 12~48V

-Rated Output: 800W

-Rated Current: 35A

-Applicable Motor: BDC, BLDC

-Motor Feedback: Hall Sensor, Sensorless; Encoder input signal is available

-Communication Interface: Built-in Wi-Fi module and RS-485; RS-232, CAN Bus for options

-Speed Control: Analog input, Digit input, PWM, Command sources

-Display: 2.8" wireless color touch screen for options

-Software: Equipped with dedicated motor monitoring software which is available to connect with mobile devices (smart phone, pad, notebook, etc.) through Wi-Fi.

※Features

-Integrate multiple functions to reduce the external components' cost

-Monitor the motor's status such as voltage, current, speed, etc. through dedicated software

-Data setting and devices' status monitoring by dedicated software through Wi-Fi connection

-Support different motor control modes (revolutions, distance, operation speed, etc.) and multi-step programmable settings

-Modbus-compatible driver for various host controllers.

-Over-the-air firmware update

-Multiple I/O (open collector) for flexible expansion of different applications

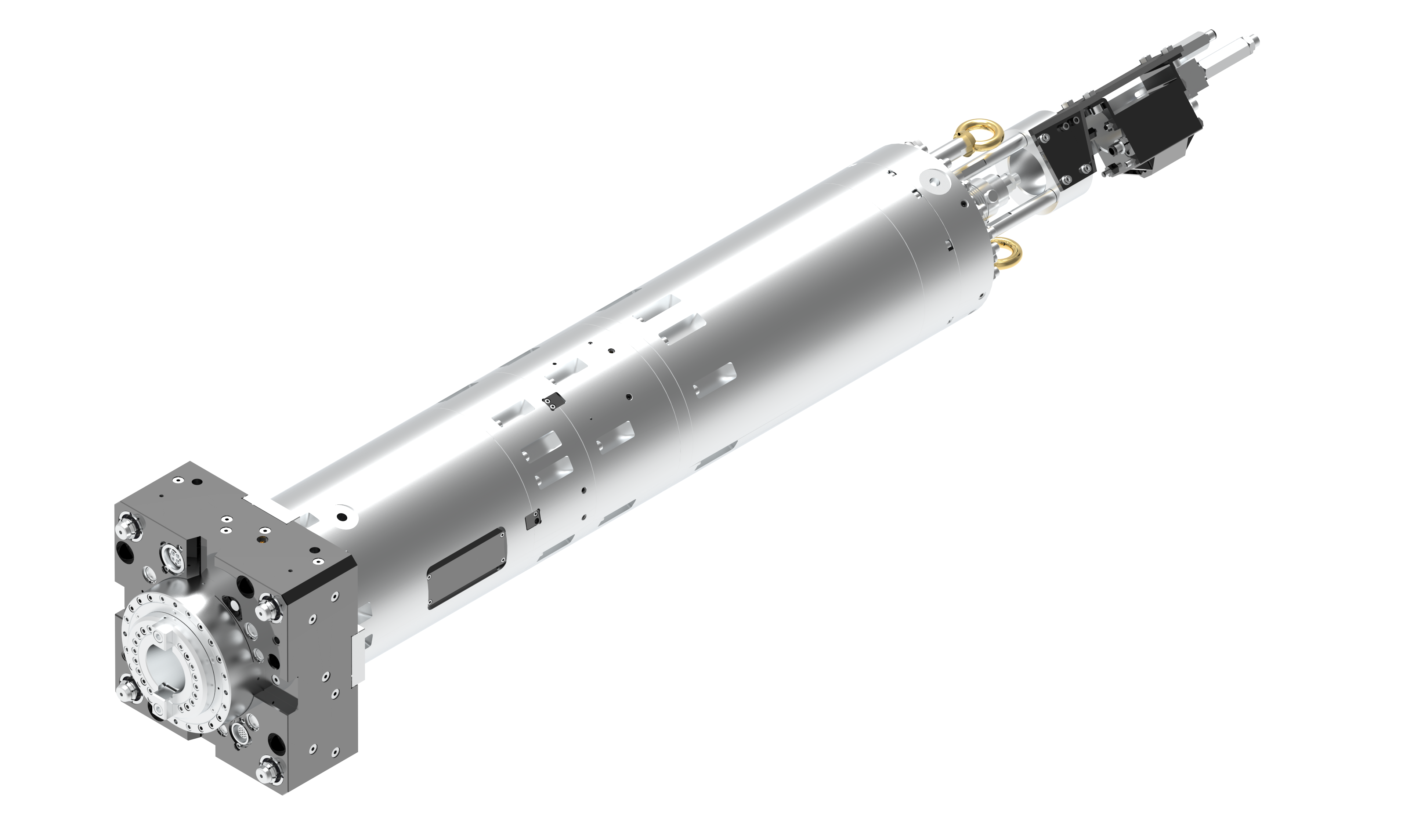

GP MACHINERY CO., LTD.

製品の説明 :

Features:

The RGB system (Ram Gear Box) is the most complete solution within this family, with important technological contents, that combines high torque performance in small dimensions particularly appreciated for vertical (gantry or double column) and horizontal axis machine tools. The general characteristics are similar to the RTS

Products:

.Automatic attachment system for the accessories (like heads or extensions)

.Multitasking machining operations.

.Easiness of assembly and maintenance on the machine with:

.Quick connections and couplings positioned at the top of the RAM

.Possibility of easy and quick extracion of the spindle from the front of the RAM.

ADLEE POWERTRONIC CO., LTD.

製品の説明 :

Product applications:

Surface grinding machine、Internal & External grinder、CNC lathe machine、CNC milling machine, etc.

Adlee manufactures V3 class of AC spindle motor. The motion of AC induction motor makes great performance and this special design for milling machine spindle.

1. V3 class spindle motor.

2. 3 phase AC induction motor has extra low vibration performance.

3. Efficiency conforms to IEC 60034-30 IE3 standards IEC motor.

4. IEC motor specifically designs for grinding machine and low vibration applications.

5. Power range is from 1HP to 20HP.

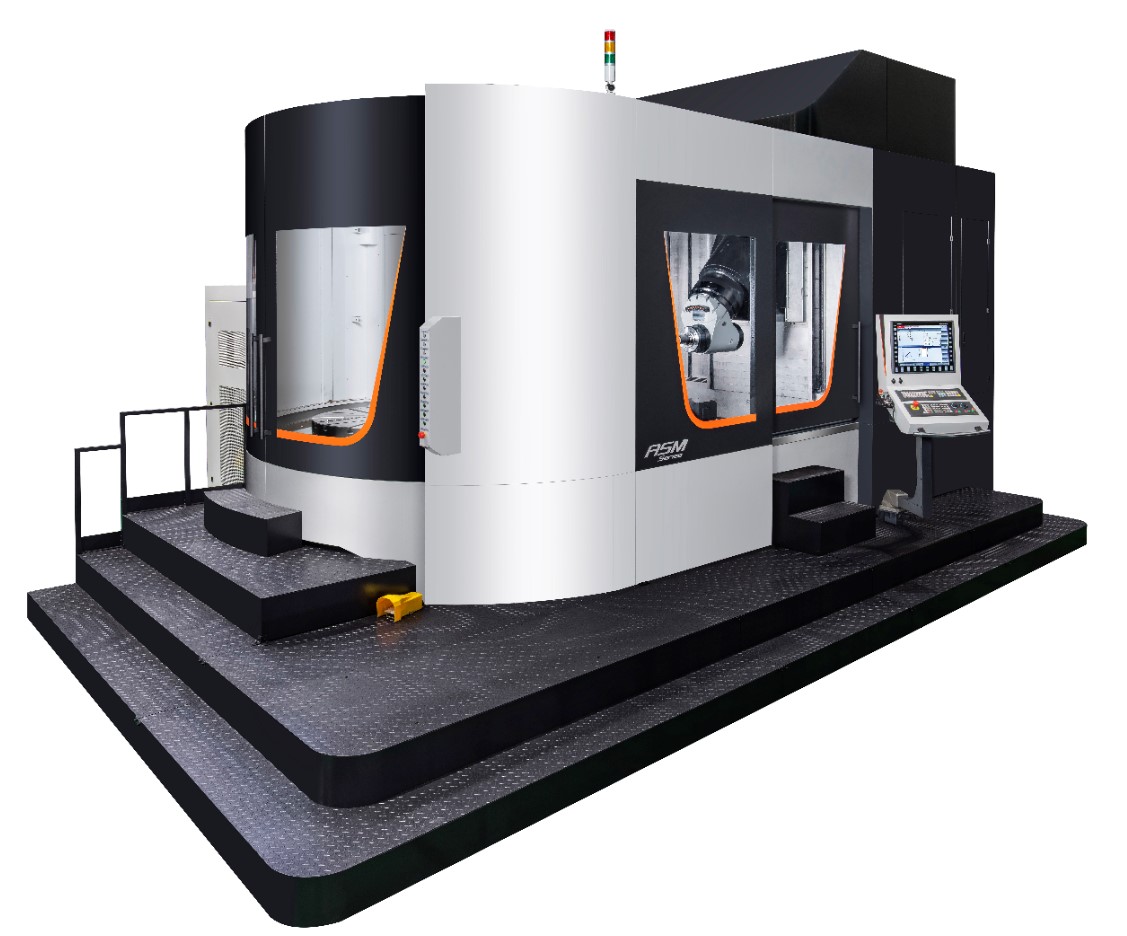

VISION WIDE TECH CO., LTD.

製品の説明 :

• ASM is the first 5-axis CNC turning and milling machining center of Vision Wide, and it is particularly designed for delicate cylindrical components machining featuring high acceleration, rapid feed-rate and synchronized axes machining, especially for aerospace components, tire molds, turbine blades and aluminum parts.

ASM accessorizes with 5-axis universal head and rotary shafts built-in D.D motor. Through topology analysis, ASM realizes the best distance between tool center point and B-axis transmission

• Positioning P0.006mm

• Repeatability Ps0.0055mm

• Spindle thermal compensation 0.02 mm

• Rapid Traverse 40m/min

• Acceleration 0.3G

• Cutting Feed rate 24 m/min

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

X axis travel:

Single movement: 2550 mm (100") inch

Dual movement: 1275 mm (50") inch

YZ axes travel: 850x600 mm (33"x24") inch

※Y axis can be increased to 1300 mm(51") (Option)

※Z axis can be increased to 1000 mm(39") (Option)

Work table: 3100x1600 mm (122"x63") inch

Max. Workpiece: 4100x2050x1250 mm (161"x81"x49") inch

Max. Workpiece weight: 22000 kg

Max. electrode weight: 500 kg

Machine net weight: 29410 kg

Oil level: 110-1000mm (4"-39") inch

Occupy size(LxWxH): 6480x6600x4600 mm (255"x260"x181") inch

Work Table to platen:

600mm Z travel machine: 1138-1738mm (45"-68")

1000mm Z travel machine: 740-1740mm (29"-69")

Filter: 4

Paper filter:8

Capacity:11300 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

JASON AUTOMATION CO., LTD.

製品の説明 :

CytroPac - The compact revolution for hydraulic power units: completely equipped and integrated.

Rexroth has started the hydraulic power unit revolution. Lack of installation space is no longer a reason to go without hydraulic power: The new CytroPac power unit provides maximum power in the smallest space with everything you need for fast installation – including an economical Sytronix drive, completely wired frequency converter and Industry 4.0 compatibility. With powerful 4 KW and pressure of 240 bar in 50 percent less installation space. Furthermore, CytroPac also complies with the EU Ecodesign Directive 2009/125/EC. Simply connect power, fluid and interface and go. A small revolution!