展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

GT MARKETING Co., LTD.

製品の説明 :

Strategy-Based, Driving Brand Development:

We carry out brand development based on strategic thinking, starting from industry research and analysis, proposing decision-making basis, digging out the most suitable brand positioning, and solving business problems with design thinking. We recruit cross-field talents to assist companies in integrating brand market communication, marketing exposure planning, and visual design to achieve sustainable brand development.

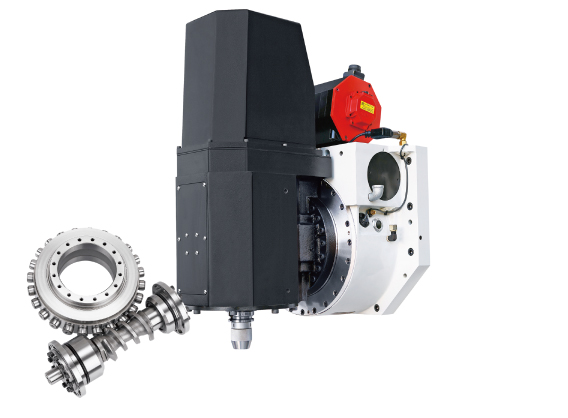

CAMPRO PRECISION MACHINERY CO., LTD.

製品の説明 :

Campro presents the new NT series CNC lathe which is based on high quality cast iron for perfect stiffness and vibration characteristics. 30° cast iron inclined bed ensures quick chip evacuation. NT-208SM equips BMT Living Turret and C-axis control which enables machine to perform milling functions. Through synchronized control of 8” Main spindle / 6” Sub-spindle to complete the greatest amount of primary and secondary turning possible in one compact platform.

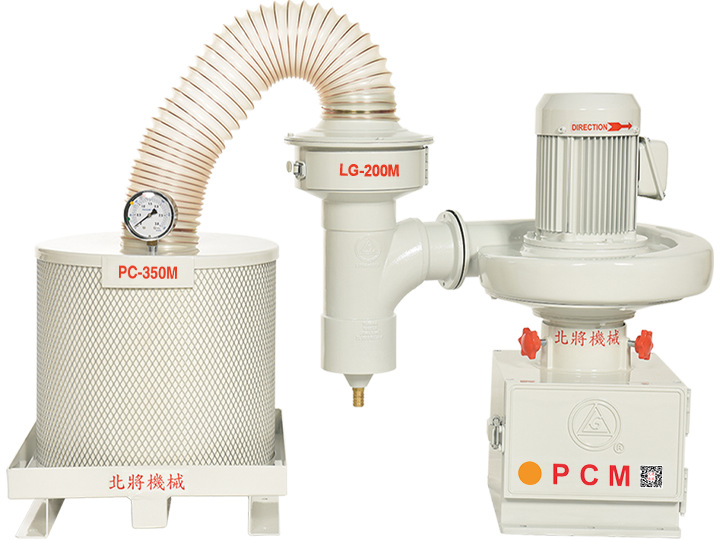

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

X axis travel:

Single movement: 1125 mm (44" )inch

Dual movement: 560 mm (22") inch

YZ axis travel 700x500 mm (28"x20") inch

Work table: 1850x850 mm (73"x33") inch

Max. Workpiece: 2800x1400x700 mm (110"x55"x28") inch

Max. Workpiece weight: 5800 kg

Max. electrode weight: 400 kg

Machine net weight:8350 kg

Oil level: 110-550 mm (4"-22") inch

Packing size(LxWxH): 5430x4600x3090 mm (214"x181"x122") inch

Work Table to platen: 700-1200 mm (28"-47") inch

Filter: 4

Paper filter:8

Capacity:3400 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.