展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

CAMPRO PRECISION MACHINERY CO., LTD.

製品の説明 :

Campro presents the new NT series CNC lathe which is based on high quality cast iron for perfect stiffness and vibration characteristics. 30° cast iron inclined bed ensures quick chip evacuation. NT-208SM equips BMT Living Turret and C-axis control which enables machine to perform milling functions. Through synchronized control of 8” Main spindle / 6” Sub-spindle to complete the greatest amount of primary and secondary turning possible in one compact platform.

ENSINGER ASIA HOLDING PTE. LTD. TAIWAN BRANCH

製品の説明 :

Polyetheretherketone (PEEK) - TECAPEEK natural is a high performance, high temperature, semi crystalline thermoplastic manufactured by Ensinger and may use Victrex® PEEK 450G or Solvay‘s KetaSpire® KT-820 polymer. The most well known and important member of the polyaryletherketone group combines excellent wear, and very good mechanical properties, even under thermal load. Outstanding chemical resistance and a high operating temperature (up to 260°C) round out its profile, and make TECAPEEK an almost universally appropriate material for highly stressed parts.

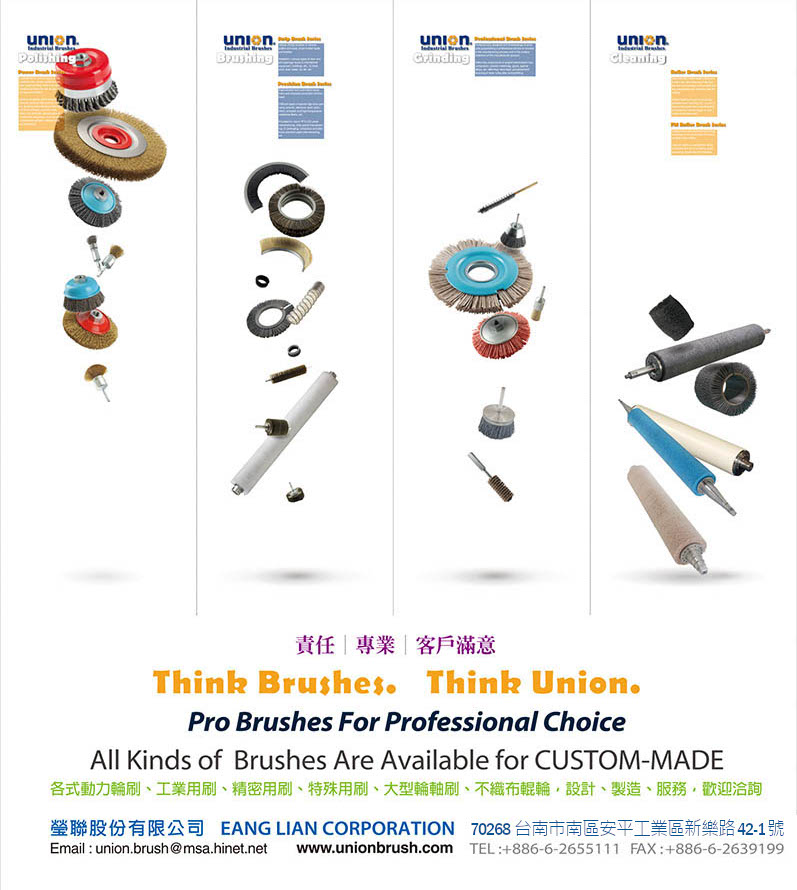

EANG LIAN CORPORATION

製品の説明 :

刷、磨、拋、洗<br />

專業化的設計能力<br />

多樣化的線材應用<br />

客制化的生產系統<br />

提供客戶製程製品-刷、磨、拋、洗.全方位的解決方案<br />

瑩聯股份有限公司—主要供應各式工業用刷是工業用刷之專業設計製造廠、擁有自有品牌(優利牌),產品適用於各行各業。無論需要刷洗、精細研磨、拋光、輕研磨、重研磨、毛邊去除、深孔加工皆有顯著效果!<br />

<br />

主要產品:<br />

1.動力輪刷系列適用於各型電動及汽動工具.<br />

2.矽砂尼龍研磨刷系列可針對各種表面精細研磨.<br />

3.輪軸刷及板槽刷系列接受各種線材及特殊尺寸訂製<br />

4.鋼鐵業退火酸洗、脫脂清洗、刷磨、清洗等大型刷輥<br />

5.德國技術合作專業生產高科技合成纖維輥適-用於鋼鐵軋片產線之刮油輥、塗油輥、擠水輥、張力輥、轉向輥、擠油輥、擠乾輥、擠壓輥、擠水輥、不織布擠水 輥。 6.各種線材及特殊尺寸可依照客戶需要量身訂製

SING CHIUN ENTERPRISE CO.,LTD.

製品の説明 :

(1) Great tensile performance, great camber.

(2) Thermal resistance range:-15℃~105℃ , Protection

degree IP68.

(3) Inner conduit is made of iron metal with zinc plating,

out layer is covered with PVC, with of waterproof

and dust proof.

(4) PT705 (3/8"~ 1 1/4") Inner conduit with copper

earth wire.

(5) According to IEC Section 351, the conduit must be

additionally attached with one grounding cable

when PT705 (1 1/2"~ 4") is constructed.

(6) Apply to conduit protection of electrical equipment

under UL standard, detection instrument, industrial

equipment and hardware work piece.

(7) Apply to electrical conduit for heavy industrial

machine motor, petrified and chemical machine,

plastic manufacturing building, power transformer

and ship manufacturing.

LNC TECHNOLOGY CO., LTD.

製品の説明 :

‧Pulse or Digital communication type

‧ EtherCAT protocol provides high flexibility of peripheral equipment connection control

‧6 path 32 axis control (max.)

‧High-speed and high-precision compensation to meet advanced turning and milling applications

‧Dual system, double feedback

‧Provide secondary development tools: HMI/PLC/Macro

‧Equipped with LNC smart vibration sensor to provide value-added functions: abnormal vibration detection, tool wear detection...and so on

‧Applications: high-speed lathe, turning-milling complex machine, dual-system lathe, double feedback lathe, gear hobbing machine

JIN TAIRY ELECTRIC CO., LTD.

製品の説明 :

JPS Technical Specifications

• Input voltage regulation range: rated voltage±15%

• Output efficiency: more than 95%

• Output stability rate: rated voltage±1%

• Waveform distortion: No distortion (compared with input waveform)

• Overload capacity: Above 150% of the rated output current

• Working environment: -0C~+40C

• Induction time: less than 0.1 seconds (less than 5 weeks)

• Working humidity: 95%

JPS Features

• Intelligent logic voltage regulation method

• Self-detection function

• LED indicator on the panel

• Patented bypass device included

• Large-range over-high and low-voltage protection device

• Under-phase instantaneous power failure short-circuit protection device

• Prevent activation of over-voltage device (SOVP)

Electronic double circuit panel design

• The internal panel voltage can monitor the three-phase voltage

• The DIP switch function is easy to set up

• Separated voltage stabilization design, three-phase unbalanced 100%

• Taiwan Patent No. 60215 62577

• Mainland Patent No. 12559 5390066

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

X axis travel:

Single movement: 1125 mm (44" )inch

Dual movement: 560 mm (22") inch

YZ axis travel 700x500 mm (28"x20") inch

Work table: 1850x850 mm (73"x33") inch

Max. Workpiece: 2800x1400x700 mm (110"x55"x28") inch

Max. Workpiece weight: 5800 kg

Max. electrode weight: 400 kg

Machine net weight:8350 kg

Oil level: 110-550 mm (4"-22") inch

Packing size(LxWxH): 5430x4600x3090 mm (214"x181"x122") inch

Work Table to platen: 700-1200 mm (28"-47") inch

Filter: 4

Paper filter:8

Capacity:3400 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.