展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

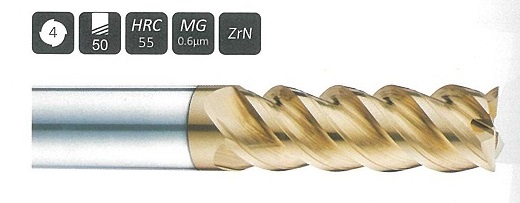

SHARPMAX TOOL INC.

製品の説明 :

● Engineered with eccentric relief for maximum edge strength in both roughing and finishing applications.

● Variable pitch geometry results in higher quality parts by decreasing chatter and harmonics.

● ZrN coating offers high hardness for estended tool life in high temp alloys and ferrous metals including stainless stee.

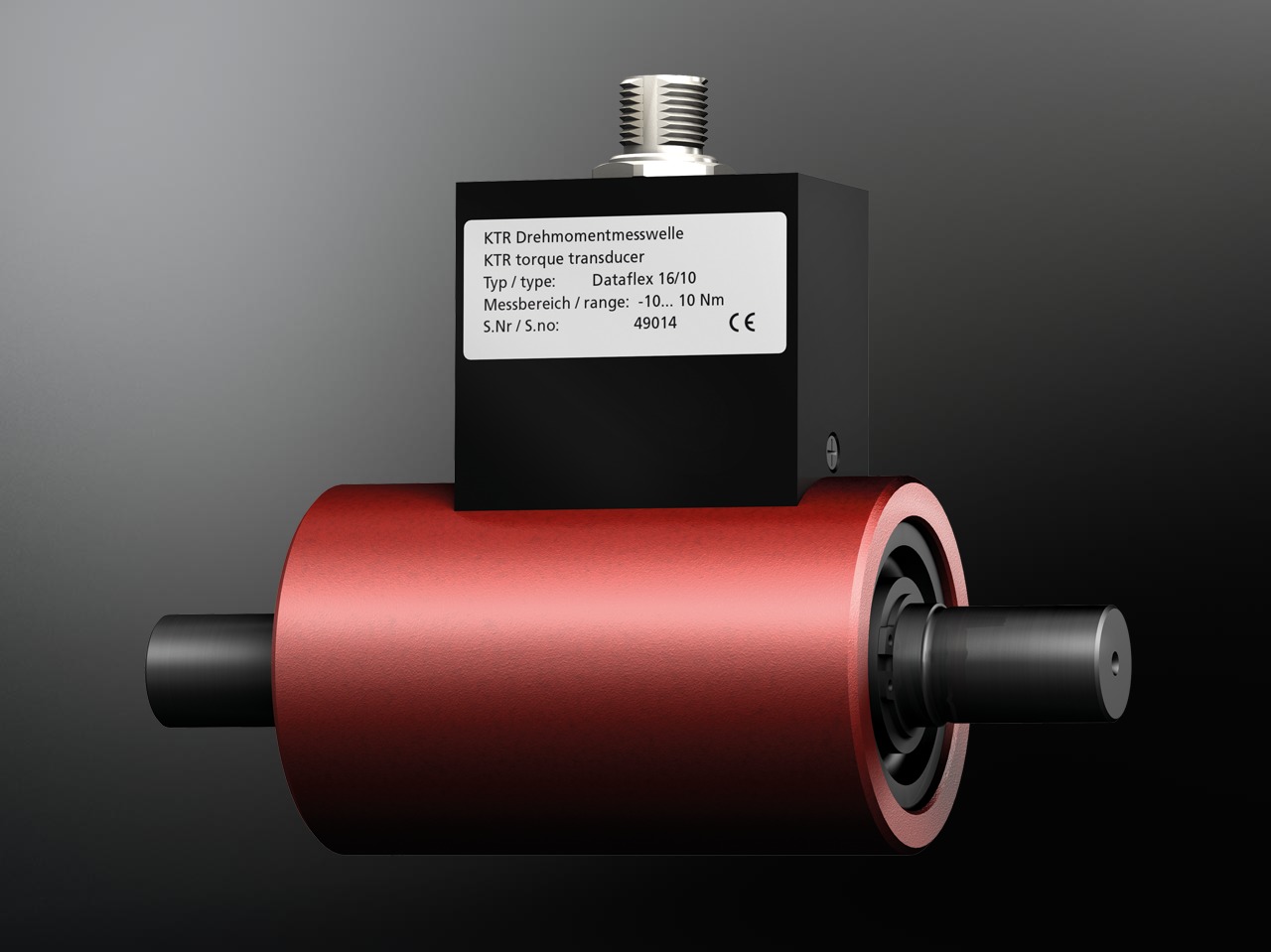

KTR TAIWAN LTD.

製品の説明 :

The recently developed DATAFLEX® 16 is available for measuring torque ranges of 10 Nm, 30 Nm and 50 Nm. The torque is measured using the well-approved technology of wire strain gauges combined with the latest electronic components.

The torque signals are processed without contact at a high resolution of 24 bit achieving an accuracy of 0.1 % of the terminal value. Supplementary to torque measuring the size 16 has a speed encoder providing two signals with a resolution of 360 pulses per revolution.

ADLEE POWERTRONIC CO., LTD.

製品の説明 :

Apply every transmission machines.

The general AC induction electric motor is designed with IEC standard. These motors fit a variety of industrial applications and it is convenient for new and used applications. Electric motor power is available from 0.25 to 20HP. The frame size is from 63 to 160.

HISEN ENTEPRISES CO., LTD.

製品の説明 :

The crystal power supply device uses high-power IGBTs to form a parallel inverter circuit.

The horizontal workstation is driven by a servo system and linear guide rails, ensuring stable travel speed. The transmission rollers are made of SUJ2 material, with weekly heat treatment and hard chrome plating, resulting in excellent strength and flatness. The system monitors the processing data of each workpiece to ensure consistent output quality.

The quenching liquid cooling system's water tank and piping are made of 304 stainless steel, and the system can monitor the water level, pressure, temperature, and flow rate.

SONG GIA INDUSTRIAL CO., LTD.

製品の説明 :

New technology for polygonal milling, one-piece design, optimised machining efficiency!

●Efficient Polygon Milling: Supports multi-surface machining of 2, 4, 6, 8, and more. A single tool can handle multiple requirements, flexibly adapting to various lathe equipment and speeds.

●Integrated Blade Design: The blade and cutter head are welded as one unit, eliminating the tolerance issues common with traditional tools, enhancing installation ease and cutting precision.

●Optimized Production Efficiency: A more efficient cutting process that reduces machining time, lowers costs, and significantly improves production efficiency.

●Precision Machining Solution: Overcomes the precision degradation problems of ordinary milling cutters, providing stable and high-quality machining results.

Choose SONG GIA's Polygon Unit for Sub Spindle to enhance your machining efficiency and achieve the perfect combination of high efficiency and precision!

SONG GIA provides you with diversified CNC drilling/milling whole series options to meet your various processing demands. We also provide customized design and production according to customers’ different requests.

https://www.songgia.com.tw/en/products/live-tools-for-cnc-lathes/polygon-unit-for-sub-spindle-strb412201

AUTOGRIP MACHINERY CO., LTD.

製品の説明 :

◎ Second Collet Changes Slash Setup Times.

◎ Industry-Leading Gripping Range.

◎ Ultra-Precision Accuracy.

◎ Parallel clamping over the entire clamping length

◎ Extreme Grip Force = Most Aggressive Chip Removal/Fastest Cycle Times.

◎ Maximum Rigidity Produces Superior Part Finishes.

◎ Best Tool Clearance - Critical For Live Tooling.

TAIWAN 3AXLE TECHNOLOGY CO., LTD

製品の説明 :

Colour Marking Fiber Laser

Marking Machine

Good for metal materials, All polycarbonate material, plastic Stainless steel and other metal materials surface marking.

Laser safty goggles, Simple Fixture, External red light, Foot Switch.

Taiwan laser marking software

Availavle in 9 languages, English, Traditional/Simplified Chinese, German, Japanese, Polish, Portuguese, Turkish, Vietnamese, Portuguese, Turkish, Vietnamese.

Deep engraving, Metal marking, Serial number, QR code, Data matrix all in one machine.

Auto focus up to 4cm.

3D Rotary up 120º degree.

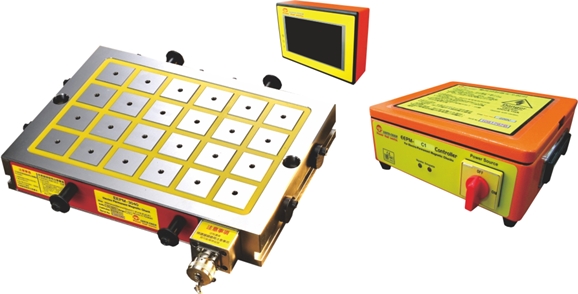

EARTH-CHAIN ENTERPRISE CO., LTD.

製品の説明 :

1.Suitable for CNC Vertical machining center (Can do 5 sides machining)

2.Suitable for thin, small , medium and large workpiece on varies cuttingmachining.

3.Suitable for thin, small , medium and large workpiece of the drilling and finishing machining.

4.Minimum size of workpiece required as 4 alternate magnetic square poles and above contacts is necessary for

optimum clamping.

5.More functions for cooperate with Induction Block and Spring Block.