展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

ADLEE POWERTRONIC CO., LTD.

製品の説明 :

Product applications:

Internal & External grinder 、Conveying equipment、Coffee roasting equipment、Centrifugal equipment、Polishing equipment、Emulsifying machine、Glass edge grinder、Auto polisher grinder, etc.

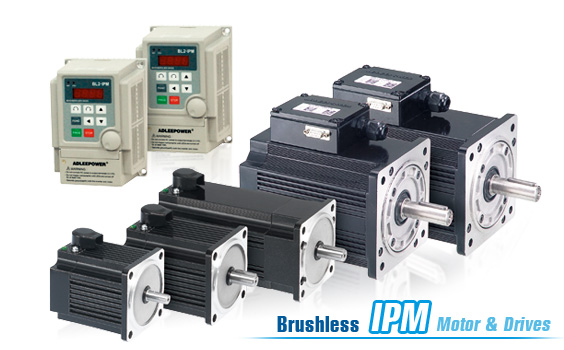

Brushless DC Motor

1. Minimize EMI and maintenance free. Low noise.

2. Specialized design to have smooth shaft rotation and improved reliability.

3. Brushless DC motor is light weight and compact size, higher power density, higher torque density and higher efficiency than conventional motors.

4. The structure has an excellent behavior in energy saving during heavy load operation. The high efficiency range is much wider than other motors too.

5. Built-in NTC thermal resistor to prevent over heat problem.

AC Driver

1. Available for all control interfaces, ex. RS 485, direct signal, PLC, HMI.

2. Convenient 220VAC driver power input from 60W. No more 24VDC power supply.

3. Built-in 24VDC mechanical brake control power.

4. Real motor speed display and signal output.

5. Panel control is always enabled with removed control or terminal control or RS485 control. Convenient for system set up or maintenance.

6. Excellent speed stability. Open loop and close loop speed control for selection.

7. With 0~5VDC, 0~10VDC and 4~20mA speed analog input.

8. Over current / heat / voltage, electric motor lock protection.

JEFFER MACHINERY CO., LTD.

製品の説明 :

JF-1600 Automatic Knife Grinder (wheel moveable version) is for grinding long and straight knives. For example, paper cutting knife, single side cutting knife, veneer cutting knife, planer knife and etc. Standard machine is for grinding straight knife length up to 1600mm. We could also extend this machine to grind straight knife length up to 2100mm. With user-friendly electronic control, it lets the operator as using it as enjoying it.

JF-1600 Feature :

1. Can obtain good, sharp knives by using a fine grinding wheel after a rough one.

2. Force cooling system gets knives neither heated, transfigured nor annealed.

3. Grinding wheel back-front movement with ball screw sets which obtain accurate and best result.

4. With magnetic chuck parallelism ± 0.02mm and high accuracy.

5. Equipped with variable speed motor for fine grinding wheel to grind high speed steel knives and carbide knives.

6. Splash guard and coolant tank are stainless steel.

7. Grinding capacity (LxWxT):1600x153x19mm

8. Fixed cutter by Magnetic Chuck.

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

1. The structure design highlights the stability during high-speed processing.

2. The base design provides multi-angle processing and improves support strength.

3. The tool length measurement device is designed inside the ATC door to avoid contamination.

4. Equipped with high-precision DD motor rotary table.

5. Sheet-metal integration reduces assembly time.

6. Internal bevel design to avoid chip residue.

7. Multi-window device improves operation convenience.

8. Could be equipped with automation/remote monitoring to improve production efficiency.

9. Ergonomically designed to reduce operator fatigue and improve safety.

10. Small footprint improves equipment utilization.

11. High Speed, stability, and precision provide a competitive edge in precision mold and die machining.

Dah Young Vacuum Equipment Co., Ltd.

製品の説明 :

High Power Impulse Magnetron Sputtering (HiPIMS) is a high-power pulsed power supply system used on magnetron sputtering coating technics. Compared to the traditional DC sputtering system, HiPIMS could generate tens of times higher pulsing current to obtain a ten thousand times higher-density electron plasma. Effectively enhancing the ionization rate to obtain a non-porous, high density crystallinity film at lower coating temperatures.

DAH YOUNG's DYHC HiPIMS series sputtering coater power supply and chamber cavity are designed to provide high plasma density (1018~19e-/m3) and high ionization rate (70~100%), increasing the substrate coating compactness, adhesion flatness and corrosion resistance. The lower duty cycle (<5%) results in a significant reduction in process temperature offering more substrate options on PEN, PET, etc. fiexible substrates.

Please refer to:https://zh-tw.dahyoung.com/

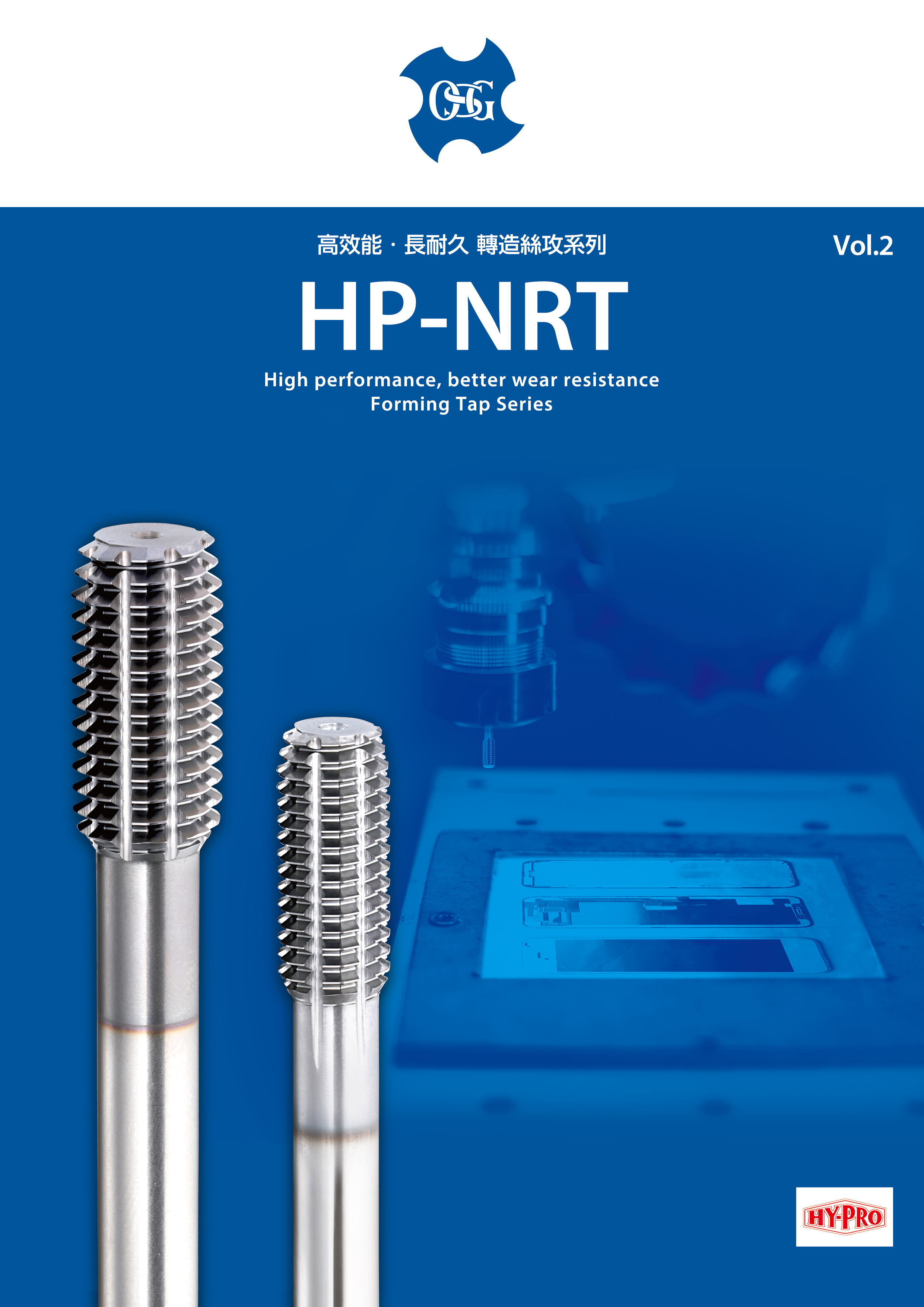

TAIHO TOOL MFG. CO., LTD.

製品の説明 :

Using powder metallurgy HSS is suitable for high hardness material tapping and stability of the tool life. Special thread design can lower the forming torque and improve the quality of internal thread after tapping. Multi-flutes design can let the cutting oil directly inject into tapping point, which can improve lubricity which effectively control tapping heat and extend tool life. TiCN coating provides welding and wear resistance ,which can lengthen the durability of taps. Special thread design can lower the forming torque and improve the quality of internal thread after tapping. Multi-flutes design can let the cutting oil directly inject into tapping point, which can improve lubricity which effectively control tapping heat and extend the tool life. TiCN coating provides welding and wear resistance, which can lengthen the durability of taps.

HP-NRT series include standard type(HP-NRT), and short chamfer type(HP-SC-NRT).

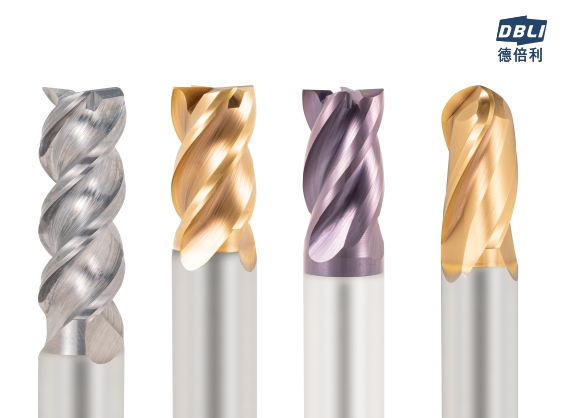

DEEP JET INDUSTRY CO., LTD.

製品の説明 :

1. Use in high speed machining and hard workpiece machining. It improves the quality and machining speed which is the best choice for precision processing.

◆Carbide Asymmetric Corner Radius End Mill (Steel)-Asymmetric helix angle 40º/42º and unequal flute design to effectively reduce the vibration rate and increase the tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 50/50.5/51 and unequal flute design to effectively reduce the vibration rate and increase the tool's stability. This makes the surface smoother.

◆Carbide Asymmetric End Mill (Steel)-Reinforced asymmetric 36º/38 º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 44.5º/45º/45.5º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

SING CHIUN ENTERPRISE CO.,LTD.

製品の説明 :

Material:

The Cable chain is injected polyester. The flange is stamped steel sheet.

Advantages:

(1) Good corrosion resistance, deformation free.

(2) Heavy duty.

(3) Adjustable length.

(4) Open protection lid for interior cablemaintenance.

Direction:

a. Not easy to twist under pressure, rail is able to turn on.

b. Apply to heavy carrying capacity and middle-long movement.

c. Apply to computer controlled machine tool, milling planner, machining center, airspace flyover, reservoir strobe, automatic warehouse, and industrial machinery.

CAMPRO PRECISION MACHINERY CO., LTD.

製品の説明 :

CAMPRO develops a proprietary system combined with precision tooling/material cabinet to assist customers in managing and analyzing tooling/material usage, 24 hours to get tools or materials and early-warning or alert notifications. The T Series are focus on cutters which is able to adjust the width according to different cutter such as milling, drilling, end-mill, tapping and so on. The patented transmission system allows user to select and dispense, withdraw cutters easily. Available to augment cabinets, max. support 100 cabinets. (Disc Type Cabinet, Tools Holders Cabinet, Recycling Cabinet, Compartment Type Cabinet, and Drawer Type Cabinet)

RICH SOU TECHNOLOGY CO., LTD.

製品の説明 :

1. Automatic separating the parts and blasting abrasive, reduce the blasting time.

2. Equipped with air flushing dust collector, which automatically separate the dust. Correspond with the environment protection test and avoiding pollution problem.

3. Diagonal type blasting method. The operator can work and check the parts directly, which can avoid the parts missing.

4. Simulating the blasting angel and intersect blasting by CAE computer in order to achieve the surface blasting action more efficiently.

5. Suitable for bicycle and auto mobile parts, blasting efficiency increase and reduce the producing cost.