展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

YI HSIN TECHNOLOGIES CO., LTD.

製品の説明 :

JIHSENSE INDUSTRIAL37JS F200 TOOL HOLDER PULLING FORCE MEASURING DEVICEJS-F200 拉刀力計係結合本公司力量感測器及掌上顯示器而成之高精度拉刀力測試器,使用應變規為感測元件,變形量小,精度高。適用於 7/24 錐度刀把。一體式的設計,簡潔美觀,免除拉線的煩惱;顯示器使用 LCD 顯示螢幕,省電美觀,具高點保持、自動歸零功能,並可設定三種顯示單位,特別設計的省電線路及自動斷電功能,增長電池使用壽命。握把使用高強度鋁合金重量輕易於攜帶:JS F200 is a high-precision tool holder pulling force tester. It use the strain gauge for the sensing element, with small deformation and high precision. Applicable to 7/24 taper spindle. It integrated the load cell, signal processing unit and LCD display, to a compact measuring device. No connector and cable on it, simple and beautiful. Specially designed auto power off function, increase battery life.

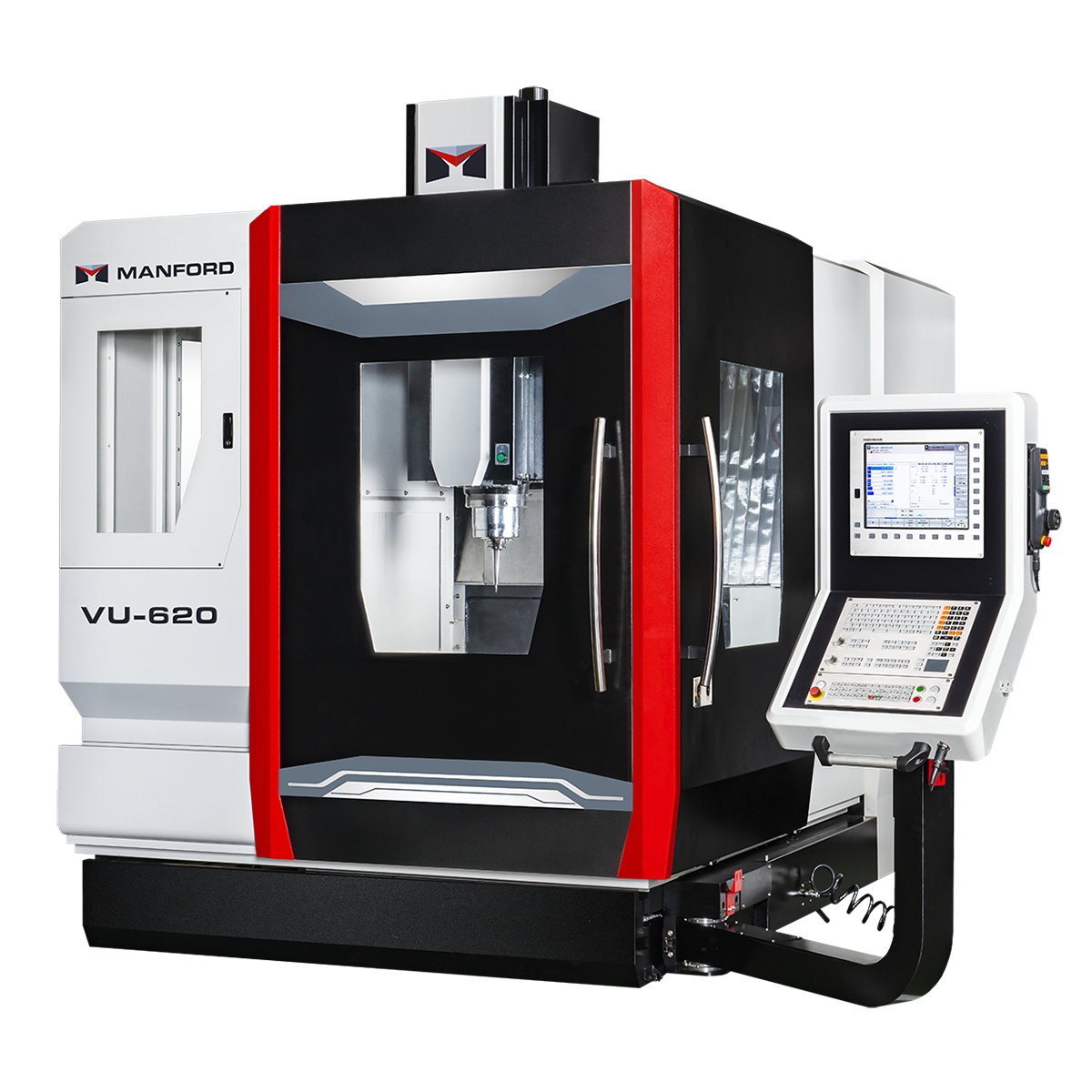

MANFORD MACHINERY CO., LTD.

製品の説明 :

Turnkey solution of VU-620 product line enables Manford to process and optimize parts efficiently, enhance productivity and accuracy. VU-620 adopts low-pollution components and complies with eco-friendly regulations. Occupying compact floor dimensions is also one of the features of VU-620.

VU-620 offers high speed, high accuracy and more reliable quality. Twin doors design with wide open space is easy for loading workpiece. Movable column C-shape provides superior rigidity. Rotary table with one-piece iron casting provides excellent ductility and greater anti-vibration. Rotary table selection: standard worm gear, or double DD motor.

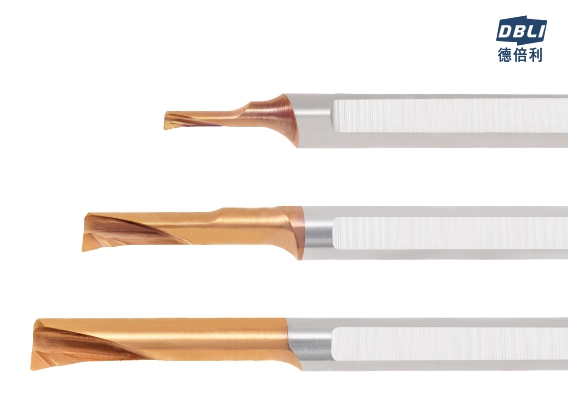

DEEP JET INDUSTRY CO., LTD.

製品の説明 :

1. With excellent features of coating to increase the tool's wear resistance and thermal conductivity to reduce the chip residue problem.

2. Use special flute design to decrease the chip-off problem during machining.

3. Increase machining accuracy and surface roughness.

PEIPING PRECISION ENTERPRISE CO., LTD.

製品の説明 :

*Automatic spindle polishing control.

*Keep the precision of spindle and no damage to spindle body.

*One setting for the maximum convenience of operation.

[After Use]

*Extend the life of cutting tools.

*Increase workpiece accuracy.

*Reduce the spindle vibration and extend the life of spindle.

HOLDING ELECTRIC CO., LTD.

製品の説明 :

The magnetic grinding machine is an innovative product of Holding Electric, and has won invention patents from many countries in the world

This patented device generates a magnetic field that motivates magnetized pins to bounce rapidly and to grind parts

Features

1.For High Precision

2.Grind Every Corner:

Effect

1.Deburring

2.Polishing

YEU-LIAN ELECTRONICS CO., LTD.

製品の説明 :

We customize CNC MPG pendant encoder, comprise antistatic protection, reversed voltage protection from DC5V to 24V. Rugged model with IP67 dust-proof, oil-proof and waterproof, ergonomics design is much easier to use and smooth handling. Depending on actual needs, axis and multiplication selections can be set; function buttons, emergency stop switch, enable switch, indicator light and wire length are also optionally available.The MPG pendant handwheel is easy to install with multi-conductor cables, and can print the company logo on the manual pulse generator wheel cover. Manual pulse generator box, MPG box, Handle box MPG can choose 100 PPR pull-up, 25 PPR pull up, 100 PPR line driver, 100 PPR open circuit... etc.. Support CNC system like FUNAC, SIEMENS, MITSUBISHI, FAGOR, HEIDENHAIN, LNC, SYNTEC, GSK and other industrial CNC machines.

G-TECH INSTRUMENTS INC.

製品の説明 :

The performance of the spindle is an important key to processing quality. When you understand the performance of the spindle, you can predict and control the quality of the processed parts. The shape accuracy, roundness, and surface roughness of the workpieces are all related to the performance of the spindle. Only when the spindle is real measuring the accuracy of the spindle at the processing speed of the machine has meaning to the control of the quality of the processed parts, so measuring and understanding the performance of the machine tool, finding the best working speed, determining the warm-up time, even confirm the accuracy of the spindle after the collision.

LION provided this SEA analysis system as early as 1993 to help spindle manufacturers, machine tool factories and processing plants to reduce workpiece defect rate and improve product quality.

★The SEA system complies with the following international standards:

✓ ANSI / ASME B5.54-2005: "Methods for Performance Evaluation of CNC Machining Centers"

✓ ISO230: Test Code for Machine Tools, 3: "Determination of Thermal Effects" 7: "Geometric Accuracy of Axes of Rotation"

✓ ANSI / ASME B5.57-1998: "Methods for Performance Evaluation of CNC Turning Centers"

✓ ANSI / ASME B89.3.4: "Axes of Rotation, Methods for Specifying and Testing"

CHIEN CHENS MACHINERY CO., LTD.

製品の説明 :

Specification

Table size: 1515 x 470 mm

Longitudinal travel: 1300 mm

Cross travel: 600 mm

A axis travel: 370 mm

Y slide way width: 720 mm

Z Slide high: MAX 700 mm

Z Slide way width: 420 mm

Spindle taper: NT#40(BT)

Spindle motor: 5HP / 4P

Spindle speed: 70~3600 RPM

Horizontal Spindle motor: 5HP / 4P

HorizontalSpindle speed: 70~3600 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø32 mm C5

Net weight: 3500 kgs

HYDROKOMP GmbH

製品の説明 :

The rotary lever clamp is especially suited for clamping fixtures with only little space for the installation of clamping elements. Its construction and compact design allows flexible solutions at various installation conditions. HYDROKOMP offers hydraulic rotary lever clamps which are single-acting as well double-acting. They are used in clamping fixtures whose oil supply is made through drilled channels. To swing down the clamping arm, the linear motion is used pro rata which clamps the workpiece. To unclamp, the clamping arm swings back to where the workpiece can be safely taken out.