展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

LNC TECHNOLOGY CO., LTD.

製品の説明 :

‧Pulse or Digital communication type

‧ EtherCAT protocol provides high flexibility of peripheral equipment connection control

‧6 path 32 axis control (max.)

‧High-speed and high-precision compensation to meet advanced turning and milling applications

‧Dual system, double feedback

‧Provide secondary development tools: HMI/PLC/Macro

‧Equipped with LNC smart vibration sensor to provide value-added functions: abnormal vibration detection, tool wear detection...and so on

‧Applications: high-speed lathe, turning-milling complex machine, dual-system lathe, double feedback lathe, gear hobbing machine

TAIWAN MORE-CASH VILLAGE CORP.

製品の説明 :

1.Convenient Design

X, Y axis workable professional structure enhanced high-

performance cutting accuracy.

2.Cutting Capacity

Cutting diameter: Ø3~16mm;

Cutting length of work-piece end: 15mmL/max;

3.Patented Radius cutting by Dual-motor driver

The hardened treatment steel is controlled well in virtue of

natural dissipation characteristic, cutting time is greatly

shortened as the work-piece is simultaneously rotated while

cutting.

4.Quick-Work-Changing System

The work-piece is quickly exchanged with prime quality 3-Jaw

chuck system.

5.Cooling System

Dry cooling is able to connect with various pressurized air and

vacuum cleaner achieved perfect cooling effect.

6.Cutting Disc

SD#100 for Carbide, CBN#100 for HSS

7.Optional Grinding Wheel For GS-13 GS-13

SD#100 thickness 5mm, 10mm for Carbide, CBN#100

thickness 5mm, 10mm for HSS

A.Carbide end mill cutting efficiency on GS-13

■ Ø 10mm 4 flute carbide end mill is cut by SD#100 cutting

disc takes 55 seconds.

■ Ø 16mm 4 flute carbide end mill is cut by SD#100 cutting

disc takes 100 seconds.

B.HSS end mill cutting efficiency on GS-13

■ Ø 10mm 4 flute HSS end mill is cut by E60WA cutting disc

takes 60 seconds.

■ Ø 16mm 4 flute HSS end mill is cut by E60WA cutting disc

takes 110 seconds.

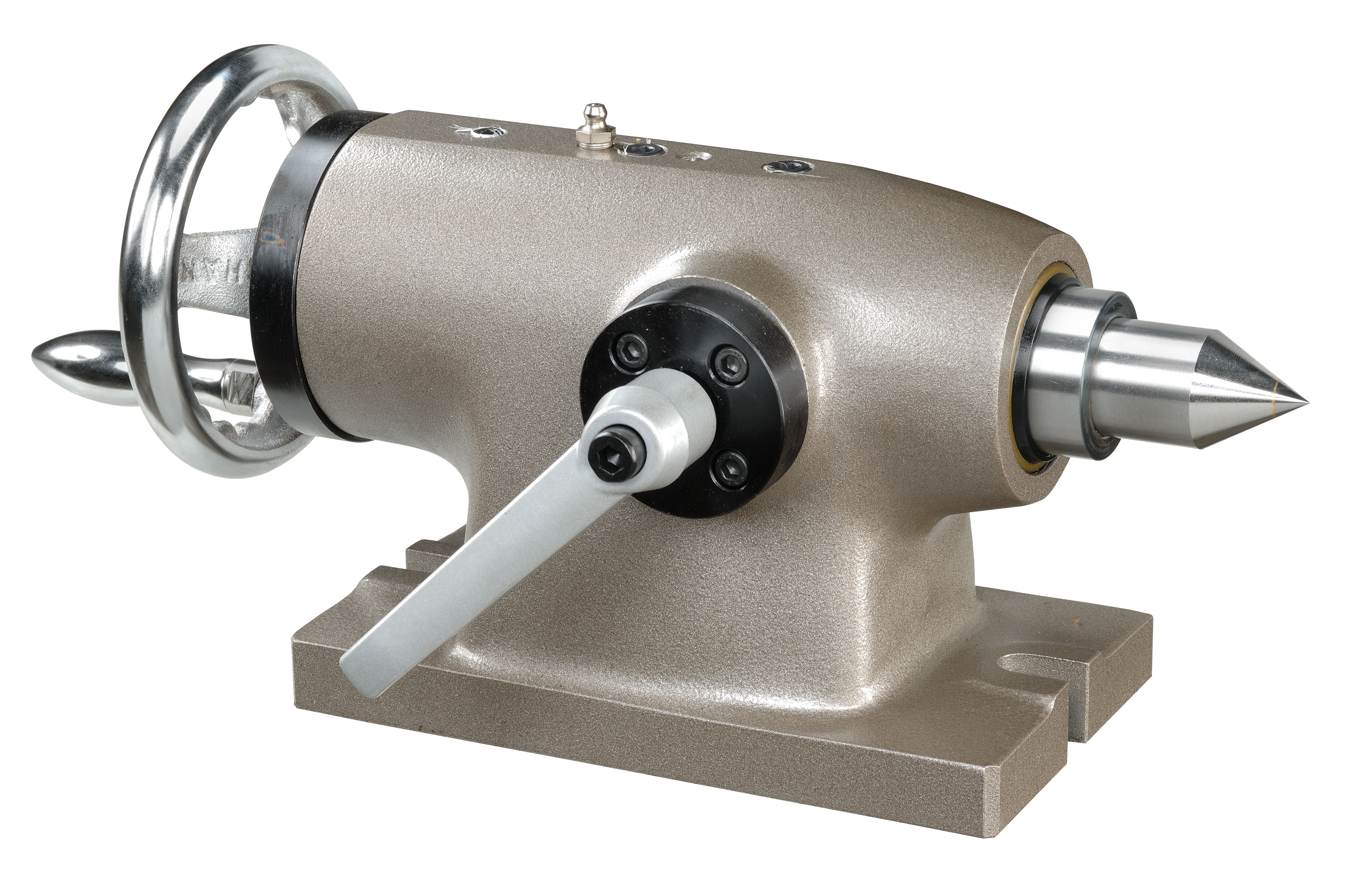

CHING HSYANG MACHINERY INDUSTRY CO., LTD

製品の説明 :

1. This machine is designed for internal and external shaving of round

tubes.

2. The center line of the processed object and the insert head is accurate.

3. The clamping die and the insert head are designed to be uniform, and

the work piece can be processed uniformly at one time.

4. The insert head is specially designed, the blade is standardized, and the

adjustment tool is simple and fast.

5. Feeding by manual, automatic advance and retreat blade, fast speed,

suitable for material steel pipe, iron pipe, aluminum pipe, copper pipe,

stainless steel pipe, plastic pipe, non-metal material and carbon fiber

pipe.

6. The machine is randomly matched with the multiple clamp, which can

be applied to different pipe diameters, saving time and cost for

replacing the clamp.

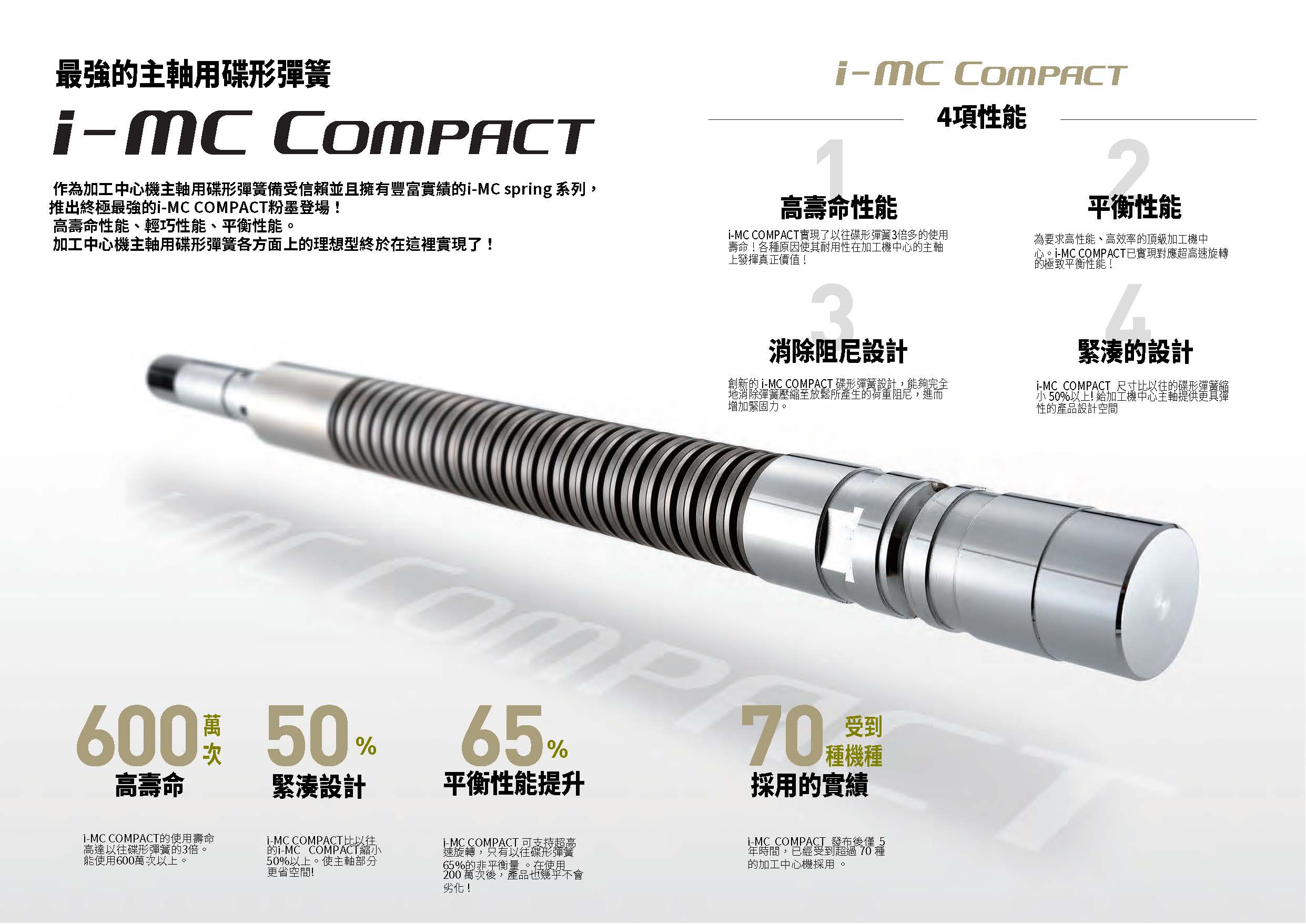

Tokai Spring industries, Inc.

製品の説明 :

i-MC spring series has established a strong trust and reputation as disc springs for the main spindle on machining centers among manufacturers. i-MC COMPACT is a new and innovative product of i-MC spring series.

Long-life performance, compact performance and balance performance.

In all of these aspects, this new product achieves the ideal form of disc springs for the main spindles on machining centers.

REAL TERN INDUSTRIAL CO., LTD.

製品の説明 :

*RT Series cooler-Fixed tube model using

high efficient thread-rolling copper tube.

*Better heat capacity, smaller at size.

Applicable to machine tools cooling system.

*High precision and good quality on tube expanding system.

*Precise CNC machining equipment,

state-of-the-art technology.