展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

INNOSERV FA INC. TAIWAN BRANCH (BVI)

製品の説明 :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

HYDROKOMP GmbH

製品の説明 :

Coupling elements of HYDROKOMP are made of stainless materials. This enables the elements to be used for all fluids and gases that are not aggressive. Special designs eg. for water steam or other media are available on request. HYDROKOMP offers coupling elements for two different operating modes depressurized coupling or pressurized coupling. The elements for depressurized coupling can be coupled pressurized up to 25 bar, if the specified volume flow is not be exceeded. When using higher operating pressure there ockures a risk of demaging the soft seal in the check valve as the result of high flow velocities of the fluid. This means for coupling of air up to 10 bar there should be always used the coupling elements for depressurized coupling. This also applies when the coupling process is initiated pressurized. The elements which can be coupled pressurized may be coupled up to the maximum specified operating pressure on one side and / or on both sides.

TAIWAN ASAHI DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

* Processing Method|Cutting Tools

* Applications|Automotive Parts, Aerospace Industry

Customized turning tools, end mills and reamers with special cutting edge treatment can divide swarfs into smaller pieces to avoid swarf tangling and residue inside the workpiece. They can meet various mass production and customization requirements (workpiece finish, etc.).

* Processing Material | Aluminum, copper, cast iron, alloy steel and other materials

TORNG INDUSTRIAL CO., LTD.

製品の説明 :

* To provide cooling, lubrication and chips removal functions simultaneously.

* It's designed for machinability, machining speed and extend the tool life.

* To save machining time and reduce machining cost.

* To ensure high quality of machining and cutting performance.

TAIWAN INSTRUMENT CO., LTD.

製品の説明 :

Nikon MM-400N 高精度工具顯微鏡,搭載鑄鐵合金機身及載物台及0.1um光學尺,可量測XYZ尺寸,並且可選配高度對焦輔助器,主要在量測半導體打線及晶片,有最佳口碑及業界第一名的市占率,採用 Focusing Aid (對焦輔助) 可有效降低人為的測定誤差,提升量測精度,除維持粗調和微調的設計外,新增Z軸防落摔擋塊,避免人員因誤操作而造成機台或樣品撞擊,同時縮減機台縱深 30mm,空間的使用更彈性,平均使用年限超過二十年,可選搭鹵素燈或LED燈及各式廣角或鼻輪式高倍鏡頭,並可擴充2.5D影像量測軟體,亦可量測平面度,是品管最佳利器,主要應用在各大電子、精密模具加工廠及探針卡、電路板廠等

HEIDENHAIN CO., LTD. (TAIWAN)

製品の説明 :

TNC7

Innovative | Sustainable | Reliable

Continuously developed, the new software version 18 of the TNC7 fulfills many requests from users and machine manufacturers about ease of operation, reliable processes and enhanced functions.

Discover intelligent functions with which the TNC7 can assist you in your future tasks!

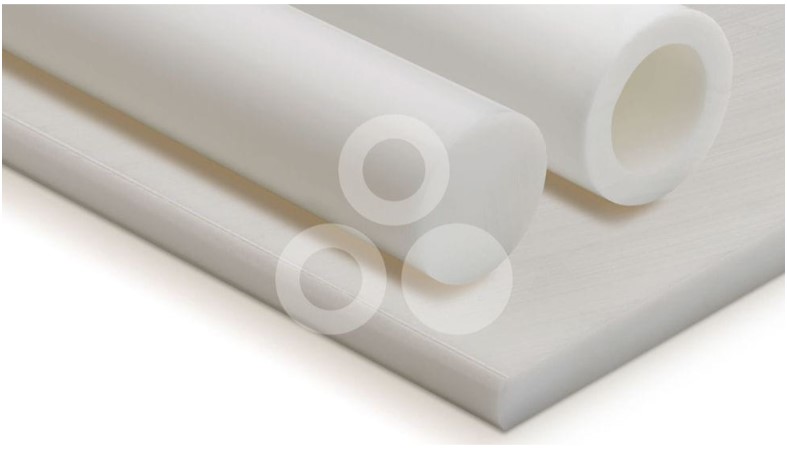

ENSINGER ASIA HOLDING PTE. LTD. TAIWAN BRANCH

製品の説明 :

TECAFORM AH natural acetal is an unfilled porosity free POM-C with a unique balance of physical properties not available in most other thermoplastics. This copolymer acetal is an engineering plastic made for wide-ranging universal applications in many different industries. The key performance characteristics of unmodified POM copolymer include high mechanical strength and rigidity, excellent wear, low moisture absorption and excellent dimensional stability. Unfilled POM-C copolymer is manufactured by Ensinger under the tradename TECAFORM AH natural, and offers high crystallinity and a good degree of toughness (even in the lower temperature range), combined with good chemical resistance.

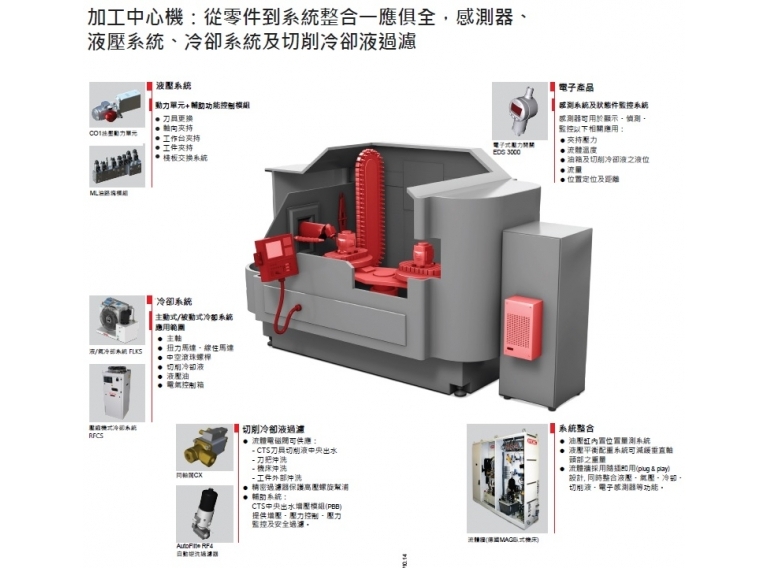

HYDAC TECHNOLOGY LTD.

製品の説明 :

HYDAC-工具機產業的最佳專業夥伴<br />

<br />

<br />

50多年來,HYDAC始終是流體技術、液壓、電子設備及冷卻系統的領導供應商,全球擁有超過10,000名員工。<br />

<br />

不僅於標準產品,HYDAC還特別專為加工中心機開發設計了各式種類的組件,包括液壓、冷卻系統、電子及<br />

切削冷卻液等領域的產品應用。<br />

<br />

HYDAC智慧整合產品,可為加工中心機提供創新及技術先進的優勢。

BORE AUTOMATION TECH. CO., LTD.

製品の説明 :

24V DC 16 Channels Relay Module, equipped with high qaulity OMRON G3DZ-DZ02P-DC24 SSR power relay, high quality WAGO PUSH-IN Type PCB terminal block, easy to replace pluggable relays, fully compatible with variety PLC /CNC controller, muti-functional protection , optimized installation effort

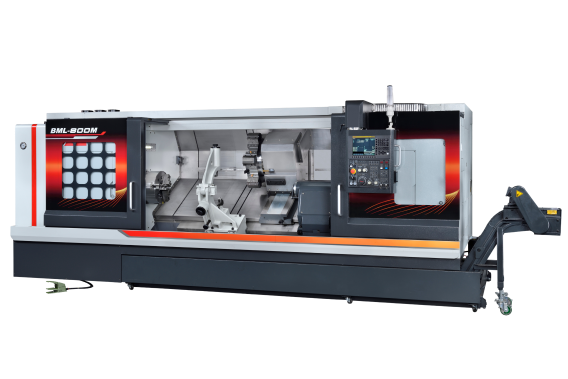

YIDA PRECISION MACHINERY CO., LTD.

製品の説明 :

The (B)ML-800 series is a highly customizable turning center with various options for spindle, gearbox, base, tailstock, turret and multiple selectable feed speeds. It can efficiently handle the most demanding machining requirements.

1. The modular structure design of the base has high strength and rigidity. It is molded as a single unit, effectively absorbing the vibrations generated by the machining and providing the stability and precision required for heavy cutting operations, without any distortion or deformation.

2. The optimal modular design spindle features high speed and power, and can be paired with a high-torque output gearbox design, offering a variety of processing options to meet different machining needs.

3. The robust toll turret design allows for quick and reliable tool changes, ensuring high efficiency and precision. It caters to the characteristics of various cutting processes, effectively enhancing machining capabilities.

3. The high-strength design of the transmission structure ensures precise positioning and greatly enhances machining efficiency and stability.

4. Ergonomically designed interface makes operation easy and maintenance convenient. Sheet metal design incorporates comprehensive safety considerations.