展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

YOUN JIN ENTERPRISE CO., LTD.

製品の説明 :

Automatic point marker is the best tool final the central poinet before punching.

It's operated to aim at the central line and be pressed downward ; the central point will appear.

The size of the point can be adjusted by the pressure lid , no need to use hammer.

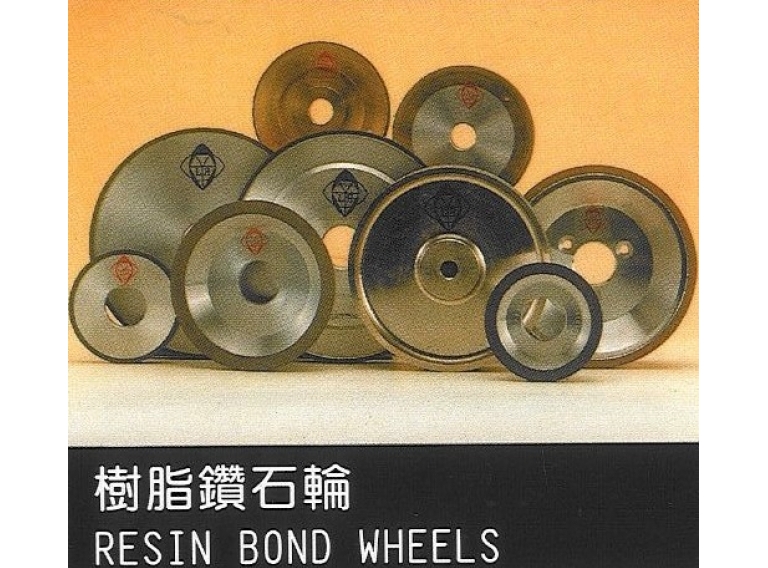

BEST DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

[AR-800 旗艦多功能型]

Multi-function Flagship Type

*With the most advanced design that provides the

multi-function of Ultrasonic, Brush DC (direct-current) and

Brushless DC output.

*All new design with high-efficiency microprocessor that

give the machine with perfect performance.

*The brushless DC with max. 250 watts and brush DC with

max. 150 watts output power that gives your handpiece

with high torque and high speed running.

*The LED speed display shows you the running speed of

brushless hanpiece. You can select the best and safe speed

according to various tools and diameter.

*Once turn on the machine, the system will automatically

adjust the speed to “Zero”, that keep you away from

the damage caused by high speed running of handpiece.

[AR-108 單功能型]

Single Function Practical Type

*Ultrasonic lapping function only.

*The machine provides reliable quality and good

performance.

*Max.40 watts output that satisfy difference of

polishing works.

*It is not only effective for lapping task, but also good for

correction of PCB patterns.

Durastar Casters and Wheels

製品の説明 :

自1985年起,美國Durastar鉅國腳輪擁有超過30年的高品質腳輪製造與PU灌注經驗,是專業的腳輪製造商,具有多樣化的產品生產線,供應北美及亞太區域各式腳輪、輪子、油壓拖板車輪、堆高機輪與客製化PU灌注。我們生產高品質的聚氨酯優力膠PU輪適用於各種行業,應用範圍重至航太工業、輕至小型推車,鉅國腳輪都能滿足您的各式腳輪與PU產品需求。 鉅國腳輪所製造的腳輪及各式優力膠PU產品以高品質與高CP著稱,省力穩定且耐用,客戶遍布世界各地,諸如美國FedEx聯邦快遞、美國甘迺迪機場行李推車、日本Bishamon毘沙門、台灣美光科技及漢翔航空工業等皆使用我們的產品。

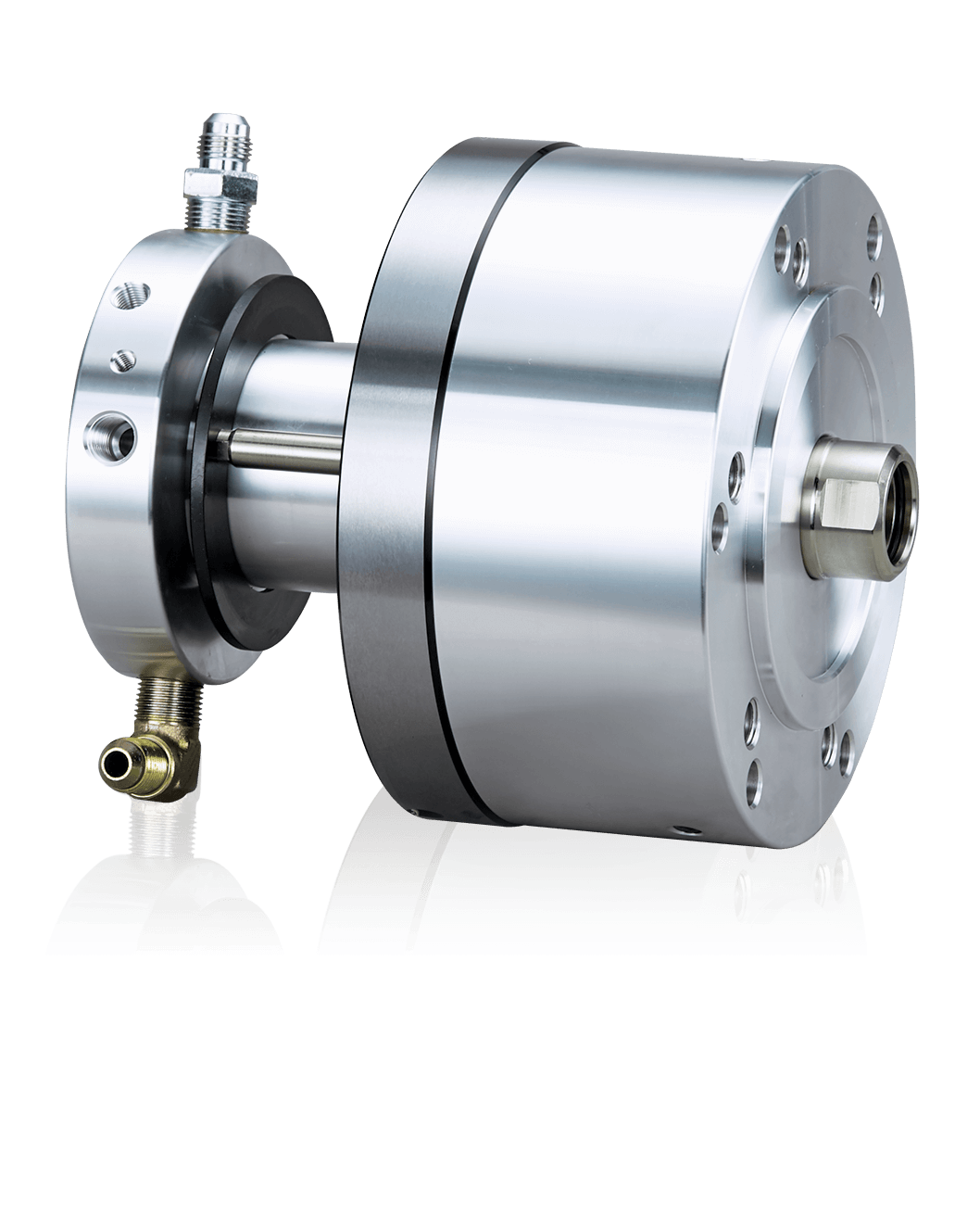

OSCAR E.D.M. COMPANY LTD.

製品の説明 :

1.X and Y sideways with manual handwheels for positioning, servo driven Z axis. COC-280 for orbit function available (option).

2.IPC industrial CPU, color LCD screen.

3.FAGOR linear scale with 0.005mm resolution (standard).

4.C7 ball screw with precisely scraped sideways, self-designed strong heat-treated FC25 casting. In combination with proper maintenance advised by OSCARMAX ensure high accuracy and reliability for decades.

5.V8 Copper and graphite special circuit to increase efficiency and minimize electrode wear-out.

6.TURBO (option) & EZ SPARK (option) - OSCARMAX selt-developed high-speed circuits help to increase efficiency and MRR of standard (TURBO) and super hard (EZ-SPARK) materials, especially for deep ribs and roughing operations.

7.Technologies for sparking steel (SKD11, P20, NAK80, STAVAX, stainless steel), aluminum, tungsten-carbide, titanium, copper, copper alloys and nickel alloys materials using graphite, copper, and tungsten-copper electrodes.

8.Memory for multiple coordinates (100 work-points).

9.DC servo drive with manual fine tuning to maintain process stability and surface integrity.

10.Remote control box for easy operation.

11.FULLY automatic programming.

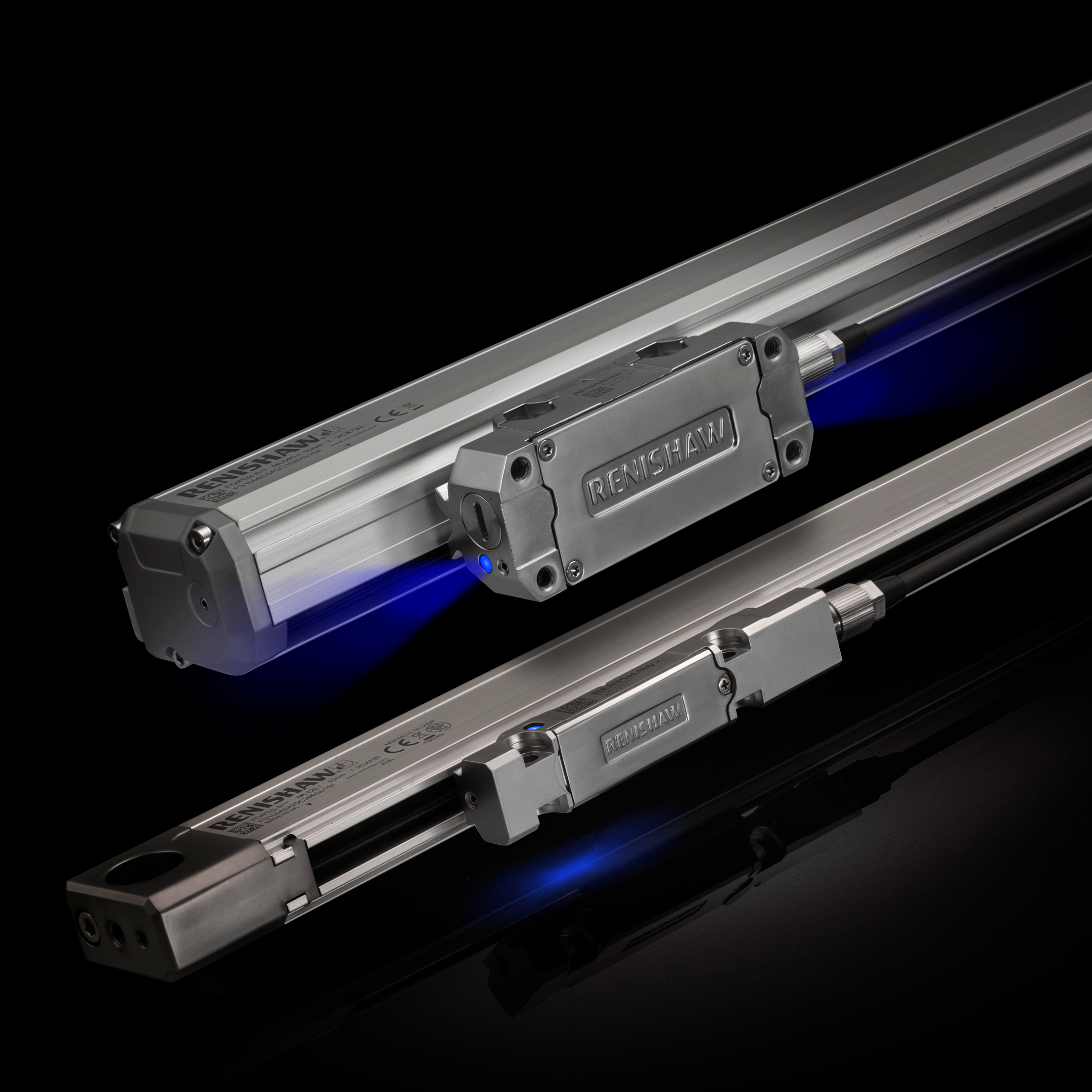

LNC TECHNOLOGY CO., LTD.

製品の説明 :

‧Pulse or Digital communication type

‧ EtherCAT protocol provides high flexibility of peripheral equipment connection control

‧6 path 32 axis control (max.)

‧High-speed and high-precision compensation to meet advanced turning and milling applications

‧Dual system, double feedback

‧Provide secondary development tools: HMI/PLC/Macro

‧Equipped with LNC smart vibration sensor to provide value-added functions: abnormal vibration detection, tool wear detection...and so on

‧Applications: high-speed lathe, turning-milling complex machine, dual-system lathe, double feedback lathe, gear hobbing machine

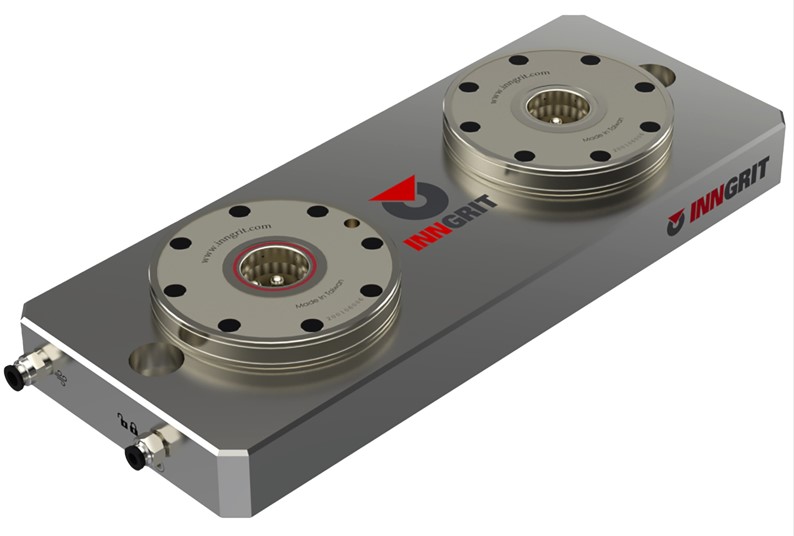

BUFFALO MACHINERY CO., LTD.

製品の説明 :

Available with two or six pallets, AXILE’s automated G6 Motorized Pallet Changer (MPC) exchanges raw workpieces and finished parts via a loading bay at the back side of the machine. Operators can load raw workpieces, and inspect and unload finished parts, while machining continues in the vertical machining center 24/7, dramatically increasing operational efficiency.

Freedom and flexibility are core to the design concept, as the MPC solution can be inte-grated upon initial commissioning of the G6 machine, or at a later stage when production capacity expands. And with the MPC-2 (the two-pallet solution), manufacturers can em-brace a Flexible Manufacturing System (FMS), of 12, 24, or 36 pallets total, by integrating one to three machines and two loading stations, depending on the scale required.

With AXILE’s digitalized intelligent automation solutions, manufacturers can eliminate production bottlenecks and ramp up production.