展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

DYNA COMPRESSOR CO., LTD.

製品の説明 :

Air end compression system

100% imported from Germany. Inorder to ensure the quality ofoperation and stable air flow of the air compressor, we use Germanhigh-precision rotors with stableperformance, excellent quality, and more durablity.

Dyna Compressor With continuous R&D and renovation, our product is advance with times, our goal is to be the most competitive brand,

professional, exquisite, design that with enough flexibility and mobility to meet challenges of the market. Customized is our standard procedure. We grab every possible chance to provide new opportunity and vitality for

industrial reengineering. Under this rapidly changing, competitive era, the

only constant belief of ours is “quality is our strength”.

Parjet Co.,Ltd.

製品の説明 :

HiPerSeal®, aka Spring Energized Seal and Teflon Spring Seal, is a U-shaped machined performance polymer that utilizes a single spring energizer to provide force for the sealing lips. The seal jacket is made from PTFE compounds using high-performance polymer fillers to enhance overall spring seal life and wear resistance properties. The system pressure ultimately increases the sealing force and creates a leak tight seal. Because the spring loaded seal utilizes a spring, slight misalignment is tolerated, and the sealing force and jacket wear is more consistent. Spring energizers are available in corrosion resistant metal alloys such as stainless steel, Elgiloy and Hastelloy to meet the most serious corrosive and high temperature applications. We offer a wide variety of springs energizers including Canted Coil springs, Helical springs and Cantilever springs. For more information, you may refer to the tab "Spring" under "Products".

Ametek Taiwan Corp., Ltd.

製品の説明 :

Talyrond 565 H/HS/T & 585 H/HS/T: It is widely used in precision machining, machinery, bearing, metrology, optics industries as a multi-functional ultra-precision roundness instrument.

Talyrond 2000:It is suitable for high precision measurement of roundness and cylindrical geometry of large, heavy or complex parts.

Talyrond 1700 & 1520 & 565XL & 585XL: The best choice of measuring large diameter parts and asymmetrical rotating parts.

Talyrond 130 & 131C & Surtronic Roundness:Powerful economic roundness and cylindricity high precision measurement system & roundness measurement instrument widely used in bearing industry workshops, characterized by fast, durable and high precision.

CAMPRO PRECISION MACHINERY CO., LTD.

製品の説明 :

NV series provide more Y-axis and more working area to meet various demands.

Heavy-duty roller type linear guideways on 3 axes which provide integration of heavy cutting ability from box way and fast movement ability from linear guide way.

Z-axis servo motor with brake replaces counter-balance to provide optimal surface accuracy on 3D machining.

Pretensioned class C3 precision ballscrews on 3 axes help to eliminate blacklash.

Bearings with dust-protection device are assembled by 3 sets both in the front and rear.

One-piece column which designed with shoulder to support tool magazine to decrease vibration and increase the machine stability while tool changes.

Optional max. 4/5-axis table diameter allows more working area and less interference between cutting tools and workpieces.

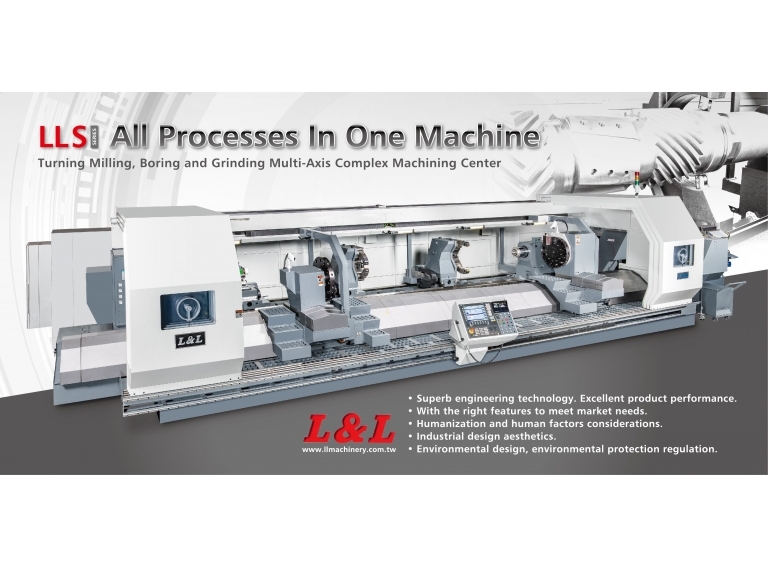

L & L MACHINERY INDUSTRY CO., LTD.

製品の説明 :

L&L LLS multi-axis composite cutting center machine, targeting the plastic rubber machinery industry, the application function exceeds customer demand:

a. Reduce the number of times of machining twice, reduce tool interference, and reduce work time by 50%.

b. Bed structure patent, one-piece casting, μ-level scraping process to ensure accuracy and stability.

c. Programmable tailstock, hydraulic center frame, independent chip removal device, programmable automatic door, high speed splash screen, full cover sheet metal design.

d. Full-cover design reduces the leakage of coolant, the design of the coolant collect plate for bed base, and the addition design of oil mist collector to reduce oil and gas pollution.

MONGTEC PRECISION INC.

製品の説明 :

◎ The general spindle speed is only 6000-15000rpm, and the tool can be pushed up to 55000rpm through 15-70bar coolant pressure, saving 70% of cycle time

◎ Various interfaces can choose BT/HSK/ER/PCS/straight

◎ Tool can be changed by ATC

◎ Display processing tool speed with chip transmission

◎ Excellent run out within 0.003mm

NINE-9 CUTTING TOOLS CO., LTD.

製品の説明 :

The “ i-Center ” is a trademark of Nine9,

the developer of the first indexable center drill in the world.(Patented)

Offering an indexable insert system for the 1st time, Nine9’s “i-Center ” design improves your process performance. Shortens set up and center drilling time.Increases tool life and reduces tooling costs.

● High Speed, High Feed Rate

• The special ground insert and rigid holder design facilitate high performance speed and feed rates. For example, drilling alloy steel

at 6000 rpm and feed rate of 600 mm/min. (0.1 mm/rev.).

● Excellent Repeatability

• The positioning repeatability of the insert is within 0.02 mm

(.0008”) in radial direction, thus ensuring conformity to any national

standards.

● Easy Tool Length Setting

• The axial position accuracy of the insert is 0.05 mm (.002”). It is

not necessary to reset the tool length when changing or cutting edge.

● Extended Tool Life

• Coolant can be supplied through the center of the holder to increase performance and extend tool life.

• Insert geometry, grades and coating process are specifically engineered for centering applications.