展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

WEXTEN PRECISE INDUSTRIES CO., LTD.

製品の説明 :

■All models use DC inverter compressors with smooth start-up, no instantaneous large

starting current characteristics, and low power consumption.

■When the heat load is low, the cooling unit operates at a low load, with high energy efficiency.

■The exclusive design of the multi-function LCD panel with an accuracy of ±1℃ can keep the

electric cabinet at a constant temperature, control heat sources, and improve the lifespan of

electronic components.

■ Uses environmentally friendly refrigerants with low Global Warming Potential (GWP) values.

■More than 95% of materials that can be recycled, contributing to environmental protection.

PROTH INDUSTRIAL CO., LTD.

製品の説明 :

1.10" touch panel.

2.The Y-axis(cross) and Z-axis(vertical) are driven by serve motor.

3.Use MPG in Y-axis and Z-axis.

4.Use PLC controller.

5.Flow control regulator is used in longitudinal way for using well.

6.Auto down feed system includes auto dresser and compensation.

7.Machinable content : surface, criss-cross, plunge, form pitch.

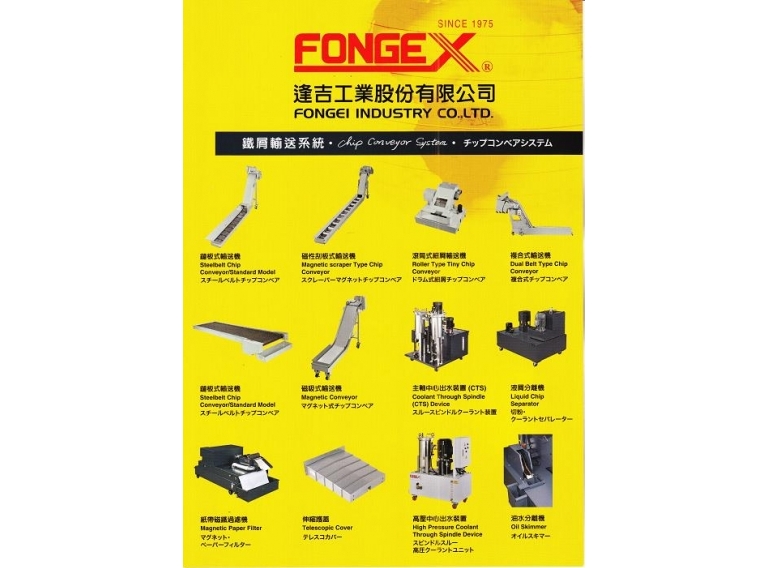

FONGEI INDUSTRY CO., LTD.

製品の説明 :

Steelbelt Chip Conveyor/Magnetic scraper Type Chip Conveyor/Roller Type Tiny Chip Conveyor/Dual Belt Type Chip Conveyor/Magnetic Conveyor/

Coolant Through Spindle(CTS) Device/Liquid Chip Separator/magnetic paper Filter/Telescopic Cover/High Pressure Coolant Through Spindle Device/Oil

Skimmer

GSTC TECHNOLOGY CO., LTD.

製品の説明 :

HWR Spanntechnik GmbH is a specialist in clamping deformation-sensitive workpieces and in compensating, concentric clamping of components of any shape. Your application in focus: With more than 30 years of experience, we know your applications inside out – and we always focus on your requirements in our developments. At HWR, innovative strength meets absolute precision in execution. The result: application-optimized clamping devices that reliably meet the increasing demands of turning. Rely on solutions that are as effective as they are economical – for optimal results in your production.