展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

CLAMPTEK ENTERPRISE CO., LTD.

製品の説明 :

The Thread-body single acting hydraulic cylinder use imported oil seal and accessories to guarantee the quality. No oil leakage while clamping in high pressure for a long time. The volume of the thread-body single acting hydraulic cylinder is small. It can be utilized in a small space in the fixture.

This hydraulic cylinder is used to extend out, and when spring returns, but it can't be used for pulling back.

The angle degree between the cylinder and workpiece could not be larger than 10° while installing.

The bottom of the cylinder barrel needs a leakage-proof gasket.

Max. operating pressure: 250 kgf/cm²

Min. operating pressure: 20 kgf/cm²

Single acting

Usable fluid:

NINE-9 CUTTING TOOLS CO., LTD.

製品の説明 :

This is a revolutionary new concept of engraving tools with indexable carbide inserts. They offer you the ability to produce HIGH QUALITY ENGRAVING in most materials.

The latest coated carbide grades help you to obtain higher speed and feed rate, dramatically reducing your cycle time.

● High Positive Rake Angle

• Indexable insert.

• Suitable for engraving all types of materials, such as plastic, non-ferrous metal, aluminum, copper, carbon steel and stainless steel.

● Multi-Side Grinding

• Full peripherally ground insert to ensure efficient repeatability.

• It performs excellently without producing any burrs, especially in copper, aluminum and stainless steel.

● High Speed, High Feed Rate

• Designed to run at high speed, up to 40,000 r.p.m.

• Feed rate 0.08mm (0.003”) / rev. apply to aluminum; 0.05mm (0.002”) / rev. apply to stainless steel.

• Reduces engraving cycle time!

● Economical

• Each indexable insert has 2 cutting edges.

• No resharpening required. Tool length is unchanged.

• No need to reset after changing insert or cutting edge.

• Excellent repeatability!

E-TECH MACHINERY INC.

製品の説明 :

EGP-2520CNC is a high-efficiency cylindrical grinding machine with ultimate reduction in footprint. With a floor space requirement of less than 1.8m2 and 500mm diameter grinding wheel, it is suitable for small workpieces machining. Distance between center is designed to be 200mm, the center height is 125mm, and the maximum weight of workpiece can be processed is 5 kilogram.

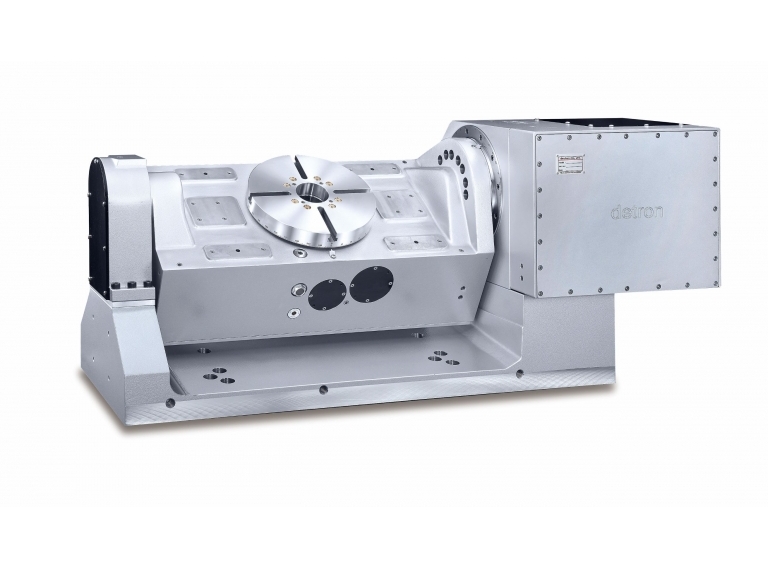

GIFU ENTERPRISE CO., LTD.

製品の説明 :

Applicable Specification:

BT40/CAT40/DIN40/HSK63/CAPTO6

Applicable Model:

Multi-Tasking Machines

1.The magazine can load 60/120/180 tools by front and rear allocation. Also, the magazine is adopted with high-quality and high positioning accuracy reducer and servo motor driven system.

2.The gripper replaces the tool pot to catch tools and achieve the purpose of lightweight and modularization

3.Innovative sub-tool pot tool catching system reduces 30% of the volume. The design of lightweight structure with fast moving speed achieves max. speed at 15m/min and the positioning accuracy of heavy loading is within ±0.1mm.

4.Two-stage advanced speedy tool changing system The best tool changing time can be adjusted according to different tool weights. The tool under 3 kg can complete tool changing procedure within 1 second.

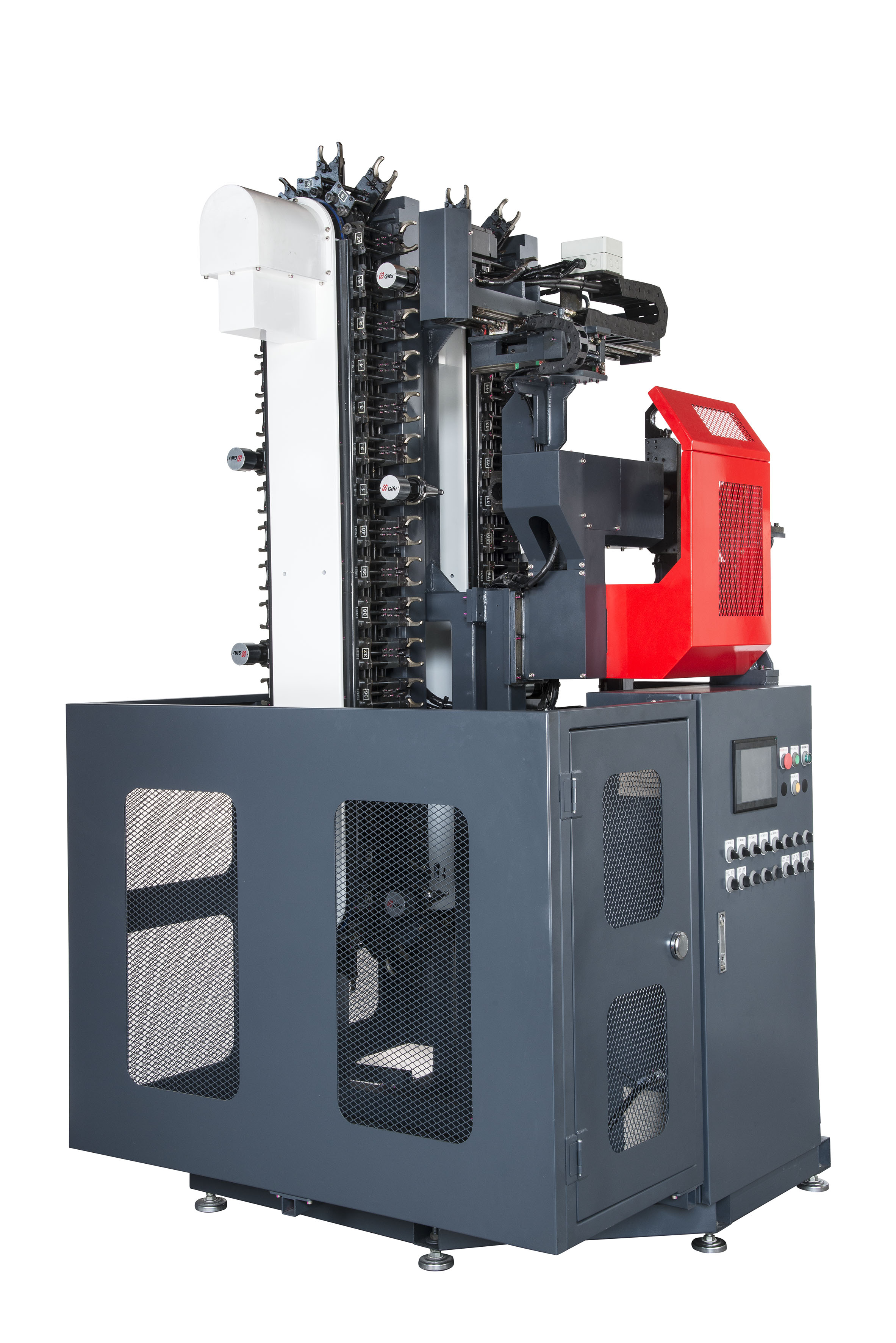

INNOSERV FA INC. TAIWAN BRANCH (BVI)

製品の説明 :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

KO-YAN PRECISE MACHINERY CO.,LTD

製品の説明 :

GJ-400 series from COMIRK combines internal grinding and cylindrical grinding in a single machine. Multiple face grinding can be accomplished with one setup for the work-piece. This machine not only saves considerable amount on machine investment costs and labor costs, but it also features dramatically upgrade for better machining efficiency and machining accuracy.

Machine Features

-Various speed of spindles selection allows for the highest grinding efficiency

-Double wheel spindles exhibit high efficiency internal and external grinding

-Internal, external, end face and tapered face can all be ground in one process

-Highly rigid machine structure ensures the best possible stability during grinding

-X, Y, Z axes are all mounted with high precision linear guide-ways.

-This machine is equipped with a FANUC CNC controller

-Multi-face grinding requires only one setup for the work-piece.

-Non-circular grinding function is available (Optional)

-Fully enclosed splash-guard

YOKE INDUSTRIAL CORP

製品の説明 :

1. 360° rotation and 230°pivot

2.Rotatable under load due to its unique ball bearing design.

3.Manufactured in accordance with EN1677‐1 and the requirements of ASME B30.26

4.Certified by DGUV GS‐OA‐15‐04

5. Forged alloy steel, quenched and tempered

6.With the Grade 100 High‐strength alloy steel, WLL is increased without increasing swivel size compared to other Yellow Point models.

7.4:1 Design factor

8.100% Magnaflux crack detected

9.Proof load at 2.5 times the WLL

10.Fatigue rated for 20,000 cycles at 1.5 times the WLL

TAIWAN ASAHI DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

* Processing Method|Cutting Tools

* Applications|Automotive Parts, Aerospace Industry

Customized turning tools, end mills and reamers with special cutting edge treatment can divide swarfs into smaller pieces to avoid swarf tangling and residue inside the workpiece. They can meet various mass production and customization requirements (workpiece finish, etc.).

* Processing Material | Aluminum, copper, cast iron, alloy steel and other materials