展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

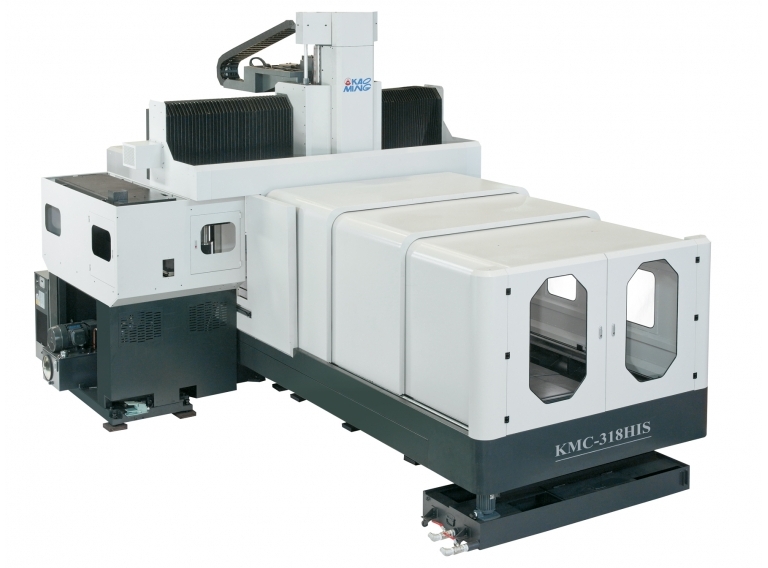

KAO MING MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

1. 門寬2.1米以下,底座採用雙線軌設計;門寬2.3米以上底座採用三線軌設計,並具有硬軌之高剛性結構,Z軸行程可達850mm。<br />

<br />

2. 三軸均配備大型滾柱式線性導軌;剛性與速度兼顧。<br />

<br />

3. Y軸採用階梯式導軌設計,上軌與下軌段差225mm的特殊設計,使主軸頭不易前傾,同時分擔了部份Y軸失利於立柱的推力,使主軸頭在重切削負荷時,非常穩定;並以垂直方式偏置排列,確保最佳結構剛性。<br />

<br />

4. 主軸以直結式傳動,減少軸不對心引起的振動,提高切削性能與精度。<br />

<br />

5. 最佳主軸頭中心對稱式設計,減少熱變位影響,確保主軸精度。<br />

<br />

6. 利用有限元素分析(FEA)先進實務觀念,設計出最佳化底座立柱及橫樑等主要結構剛性。<br />

<br />

7. 三軸使用高精度並施以預壓及預拉之滾珠導螺桿;X軸採中空設計並通過冷卻油,且螺桿兩端之稱軸承外環,有空氣冷卻之特殊設計,減少熱變形,確保最佳之定位精度。<br />

<br />

8. Z軸油壓平衡配重;在Z軸上使用兩支油壓缸抵消主軸頭重量,確保加工時的穩定性。<br />

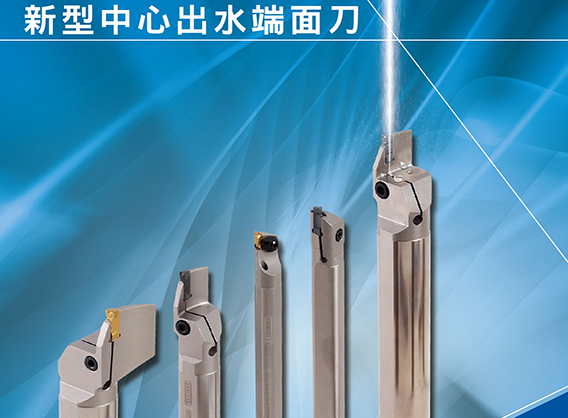

BEST DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

Compared to resin bond and metal bond wheels, Electroplated Grinding Tools are noted for relatively large grit protrusion and higher abrasive concentration. This results in very free cutting properties and in high stock removal capacity. Besides, these tools are noted for:

1. Allow special shapes and profile tools to be made at short notice.

2. Cause very little change on wheel shape after used, suitable for precision grinding.

Application and Processing Material for Electroplated Grinding Tools :

1. Internal grinding: Suitable for the internal grinding of carbide and High Speed Steel. The smallest diameter of our electroplating area is 0.3mm so it could be used in drilling for fined ceramics.

2. Jig grinding: Mostly used in fined ceramics processing and precision grinding for quartz. Customized items are also provided to cater your needs. Common grit size is #80~#325, good for rough and fine processing.

3. Touchscreen Processing: Drilling and chamfering for the glass panel of the smart phone and tablet computer. In order to improve work efficiency, we could also combine different grit sizes in the same diamond mounted point.

4. Grinding for Cutting tools: Normal end-mill grinder and drill grinder go with electroplated wheel. Carbide can be ground by diamond wheel and High Speed Steel could be ground by CBN wheel. Bowl-shape wheel with standard specification is also provided, suitable for the grinding of turning tools.

5. Precision grinding: Electroplating can produce wheel of different shapes without deforming it. Therefore, it is suitable for precision grinding or trimming aluminum oxide wheel.

6. Gem grinding: shape grinding for gem, semi-precious stones, shell and jade.

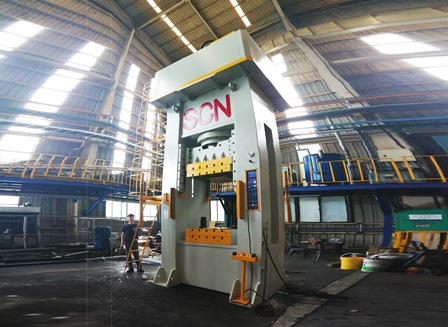

Giant Red-Wood Int’l & Co. Ltd

製品の説明 :

RW-600A Hydraulic Riveting Machine (Mitsubishi 10” HMI)

(Without Feeding System)

-Safety Device to protect finger get injured

-Proportional Value Control System

-Double-Pumps hydraulic Designed

-Auto-Riveted Counting to avoid missing riveted

-Mitsubishi 10” HMI

-Control System: Mitsubishi PLC

-Pressure Range:2-53KN(6T)

-Horsepower:3HP

-C type throat depth:450mm

-C types throat height:400mm

-Power Voltage:220V Three-Phase

*Mitsubishi 10” HMI can ensure the pressure during the operation. It also can auto-check for faulty.

*Suitable Rivet:Nut up to M10, Bolt up to M8, FH Screw up to M6 (Carbon Steel)

* Proportional Value Control System: Specific Pressure adjust bottom designed, can adjust correctly pressure within 10 second, precision within+/-1%.

*Positive Stop System: Designed for soft working pieces to ensure the flat surface. Thickness accuracy up to +/-0.05mm

*OMRON 5” HMI can ensure the pressure during the operation. It also can auto-check faulty.

*Suitable Rivet:Nut up to M10, Bolt up to M8, FH Screw up to M6( Carbon Steel)

*Pressure control easy to operate: Specific Pressure adjust bottom designed, can adjust correctly pressure within 10 second, precision within+/-1%.

*Positive Stop System: Designed for soft working pieces to ensure the flat surface. Thickness accuracy up to +/-0.05mm

Administration for Digital Industries, moda

製品の説明 :

The customer is very interested in the product and wants to further cooperate with the company, but is unable to produce a quotation on the first line. Even if a quotation is produced, it still takes a lot of time and cost to communicate with the customer and notify the manufacturer of the manufacturing plan, which ultimately results in Limited profits to be made? i+Simple assists enterprises to establish close relationships with customers. It combines accurate valuation mechanisms with CRM+SCM to quickly generate quotations based on various costs, record customer needs, and after receiving customer orders, it is connected to SCM for production operations. Assist customers in a systematic manner to deliver orders on schedule. Meet various flexible business strategies, reduce the company's operating process time, obtain more orders, master internal and outsourced production line information, and improve company satisfaction.

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

1. The structure design highlights the stability during high-speed processing.

2. The base design provides multi-angle processing and improves support strength.

3. The tool length measurement device is designed inside the ATC door to avoid contamination.

4. Equipped with high-precision DD motor rotary table.

5. Sheet-metal integration reduces assembly time.

6. Internal bevel design to avoid chip residue.

7. Multi-window device improves operation convenience.

8. Could be equipped with automation/remote monitoring to improve production efficiency.

9. Ergonomically designed to reduce operator fatigue and improve safety.

10. Small footprint improves equipment utilization.

11. High Speed, stability, and precision provide a competitive edge in precision mold and die machining.

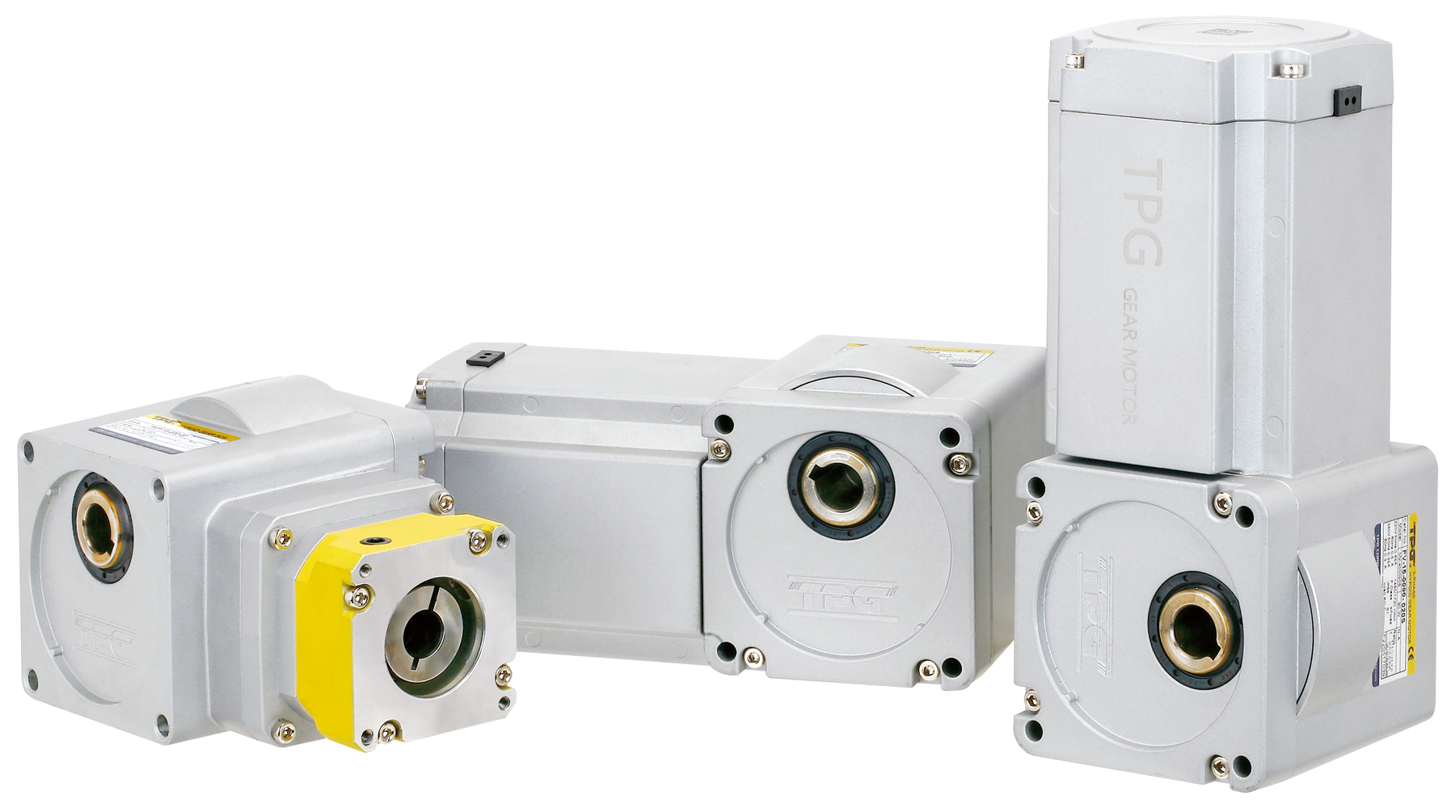

TES ELECTRICAL ELECTRONIC CORP.

製品の説明 :

FEATURE:

Six particle size channels : 0.3m, 0.5m, 1.0m, 2.0m, 5.0m, 10m

Integrated temperature / humidity sensor (no need for external add-on).

Flow rate 2.83 L/minute (0.1 CF / minute).

Rechargeable battery provides up to 4 hours of continuous operation (charge time 2.5 hours).

Buffer function allows storing and redisplay of up to 500 measurement data sets.

SD storage device.

APPLICATIONS:

Monitoring clean-rooms, manufacturing processes and pharmaceutical production.

Indoor Air Quality (IAQ) monitoring.

Monitoring gowning rooms.

Testing filter seals.

Locating particle contamination sources.

Monitoring particle size distributions.

TAIWAN 3AXLE TECHNOLOGY CO., LTD

製品の説明 :

. Processing size: 1300*900mm.

. Metal cutting configuration with Raycus fiber laser, laser wattage 1000W

. Non-metal cutting configuration 320W Co2 laser tube + professional thick plate cutting head

. Professional cutting system, "one-key switch button" on the machine, can easily switch between metal cutting function and non-metal cutting function.

. This equipment is specially designed for cutting a variety of materials, whether metallic or non-metallic.

. We combine the top-standard Co2 non-metal laser cutting machine configuration with the most popular fiber laser cutting configuration currently used in one machine

. Metal cutting head, 10mm focus Z axis direction adjustment, wide cutting range; excellent and stable beam quality, perfect water-cooled structure, advanced dustproof design, effectively avoid dust intrusion.

. Co2 non-metallic laser cutting performance can perform acrylic cutting with a thickness of 30mm. Because the laser head of this model is specially designed, it shows a bright clean surface without ripples after the acrylic cutting of thick plates.

. Optical fiber laser metal cutting performance Stainless steel can be perfectly cut to 3mm without post-processing. For carbon steel, it can also be cut to a degree of 6~8mm. It is the same grade for professional cutting applications.