展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

DKSH Taiwan Ltd.

製品の説明 :

PC F series is designed to produce maximum distillate quality with minimum capital and operating costs. Each model is a compact skid-mounted unit, simple, safe and easy to move. Control is by a PLC, including the functions of feed and discharge, therefore allowing automatic operation and minimum supervision. All models are designed for continuous operation, 24h/day, and require just electrical supply and compressed air.

PC F series evaporators operate in a high vacuum condition, with the boiling chamber pressure set at 5-6 kPa (absolute vacuum), in order to save the thermal energy produced by the heat pump. In this way the boiling temperature of the wastewater is approximately 40°C (104°F) and typical phenomena (scaling, precipitation, corrosion) which may reduce the performance are either eliminated or considerably reduced.

From 0,7 to 24 m3/day – 0.13 – 4.4 US gpm of distillate

Dramatic reduction of volumes and disposal costs

Water reuse and matter recovery

SIEMENS LTD., TAICHUNG BRANCH OFFICE

製品の説明 :

The powerhouse in the compact CNC class

With its unique CNC performance, our SINUMERIK 828D control sets productivity benchmarks when it comes to milling and turning on standard machines as well as functions to simply automate grinding machines. With new SINAMICS drives and SIMOTICS motion control motors SINUMERIK 828D is now even more productive.

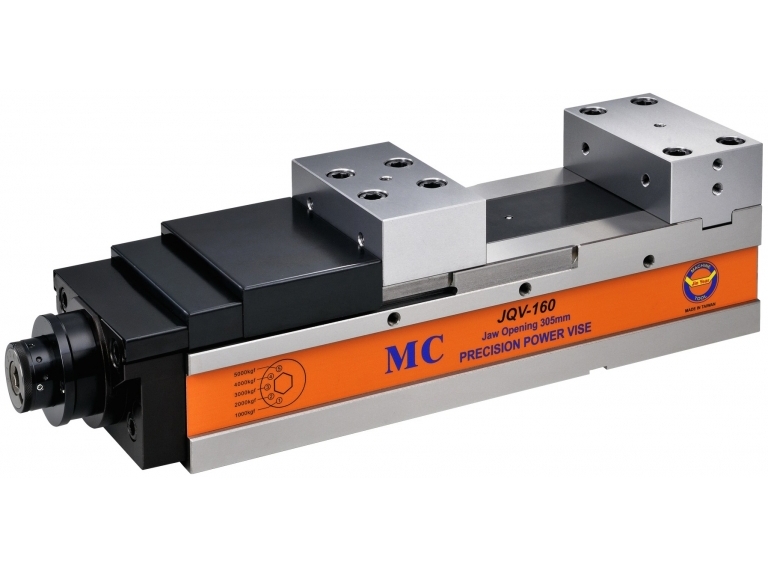

JIN YEAR PRECISION CO., LTD.

製品の説明 :

Features:

1.Pressure Constant. Clamping force can presetting, repeat use the same clamping force.

2.Vise body is made of ductile iron FCD-60.

3.Vise bed hardened to HRC45° and maintain accuracy for long.

4.Vise body height-size and the guide block side are all made with full control, can 2、3 or 4 vises to perform a job at a time.

5.The length of vise body is very short, but the clamping range is very big. It works with every kind of milling machine, CNC machine center.....

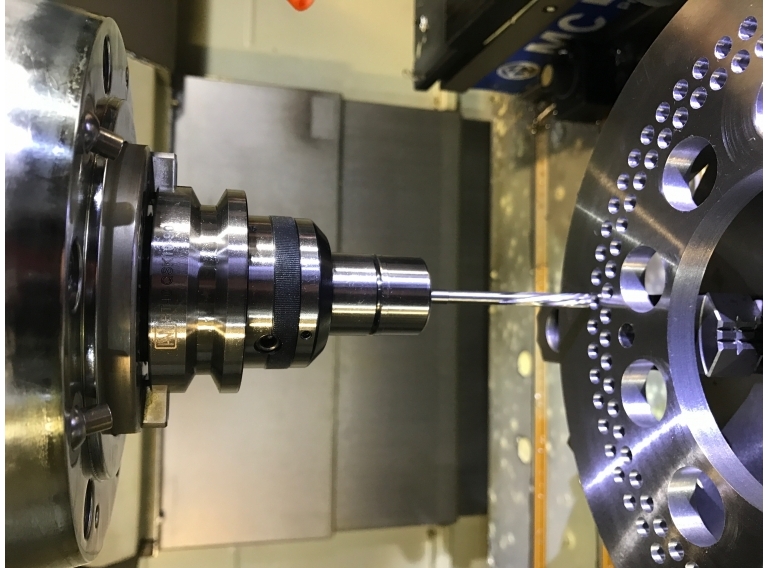

YIDA PRECISION MACHINERY CO., LTD.

製品の説明 :

The Main characteristics of Turn-Mill machine MT-540 are the orthogonal structure and rotating mill head, offering C, Y and B turn-mill capacity.

The orthogonal structure design provides wide range of travel and high dynamic rigidity. Turning combined with mill head can cut simultaneously from different direction, reduce cycle time and improve parts accuracy.

Compact and flexible machine, the MT-540 comes with maximum bar feeding diameter of 65mm. The workpiece with maximum turning diameter of 350

mm and 700 mm length can be machined.

Multi-purposed rotating components offer versatile functionality, like tailstock, loading, milling and drilling, helping the operator in practical using and long

periods of unmanned running.

YI CHANG MACHINERY CO., LTD.

製品の説明 :

This model is a Customized Machine that integrates a cam indexer. It connects a drilling machine and a tapping machine, achieving a one-time completion of drilling and tapping.

The machine's uniqueness lies in its advanced pneumatic clamping automatic feeding system, allowing operators to easily complete tasks and reducing operational burden.

Not only does this enhance work efficiency, but it also makes work precision easier to control.

In the pursuit of efficiency in modern manufacturing, our machine ensures operational simplicity, allowing you to focus more on the precise adjustments of your workpieces.

This video demonstrates how it achieves a one-time completion of drilling and tapping, providing higher work precision.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!

AUTOCLAWS PRECISION MACHINERY CO., LTD.

製品の説明 :

1. Suitable for round-bar shape objects to clamp before cutting process.

2.Using the advanced high-strength alloy steel, the key components have been treated with hardening which is strengthening the structure and enhancing the stability with accuracy and durability.

3.Large caliber design allowing the bar material go through, furthermore, it can be complemented to automatic processing eqipment for enhancing the machining efficiency.

4. The chucks complement the rotary hydraulic cylinder to provide a stable pressure for various chucking conditions.

5. Professional precision grinding makes it high-precision, precision repeat clamping accuracy, high clamping force.

RICH SOU TECHNOLOGY CO., LTD.

製品の説明 :

This machine is an improved model from the Y Rail model, featuring similar functions.

Designed standard with 4-station hanger with two side doors on blasting chamber. To meet your specific production line requirements, additional hangers are available for the entire working environment. Contact us for further details.

Features:

1.The machine employs a PLC controller for continuous cycles of blasting operation.

2.The cycle motions are: the hanging shaft enters the blasting chamber, and then moves to a fixed position at a lower speed. The door closes automatically.

Once the door is closed, the blade starts running automatically, and the machine performs blasting. Once operation is accomplished, steel balls are supplied and the blade stops automatically.

When the blade comes to a complete stop, the door opens automatically. When the door opens to the fixed position, the chain conveyor quickly delivers the nest hanging rod into the blasting chamber, then moves forward at a lower speed to a fixed position.

The door closes automatically and performs the nest cycle of blasting operation.