展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

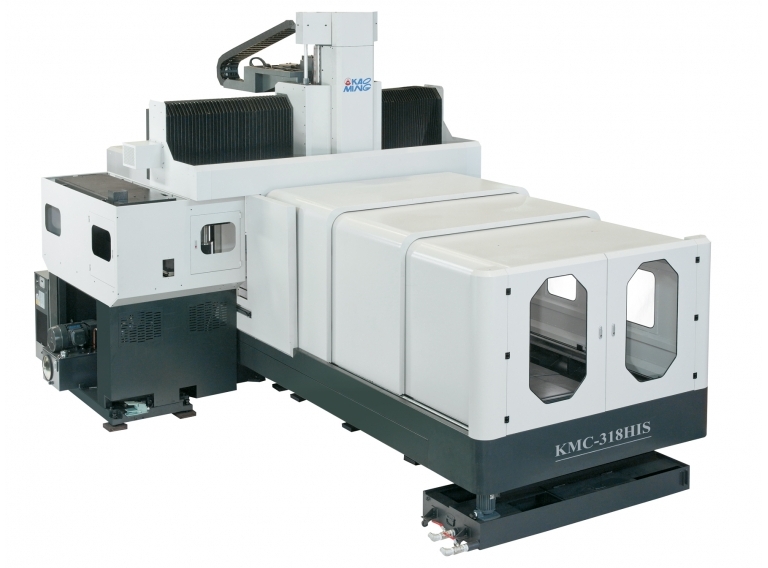

KAO MING MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

1. 門寬2.1米以下,底座採用雙線軌設計;門寬2.3米以上底座採用三線軌設計,並具有硬軌之高剛性結構,Z軸行程可達850mm。<br />

<br />

2. 三軸均配備大型滾柱式線性導軌;剛性與速度兼顧。<br />

<br />

3. Y軸採用階梯式導軌設計,上軌與下軌段差225mm的特殊設計,使主軸頭不易前傾,同時分擔了部份Y軸失利於立柱的推力,使主軸頭在重切削負荷時,非常穩定;並以垂直方式偏置排列,確保最佳結構剛性。<br />

<br />

4. 主軸以直結式傳動,減少軸不對心引起的振動,提高切削性能與精度。<br />

<br />

5. 最佳主軸頭中心對稱式設計,減少熱變位影響,確保主軸精度。<br />

<br />

6. 利用有限元素分析(FEA)先進實務觀念,設計出最佳化底座立柱及橫樑等主要結構剛性。<br />

<br />

7. 三軸使用高精度並施以預壓及預拉之滾珠導螺桿;X軸採中空設計並通過冷卻油,且螺桿兩端之稱軸承外環,有空氣冷卻之特殊設計,減少熱變形,確保最佳之定位精度。<br />

<br />

8. Z軸油壓平衡配重;在Z軸上使用兩支油壓缸抵消主軸頭重量,確保加工時的穩定性。<br />

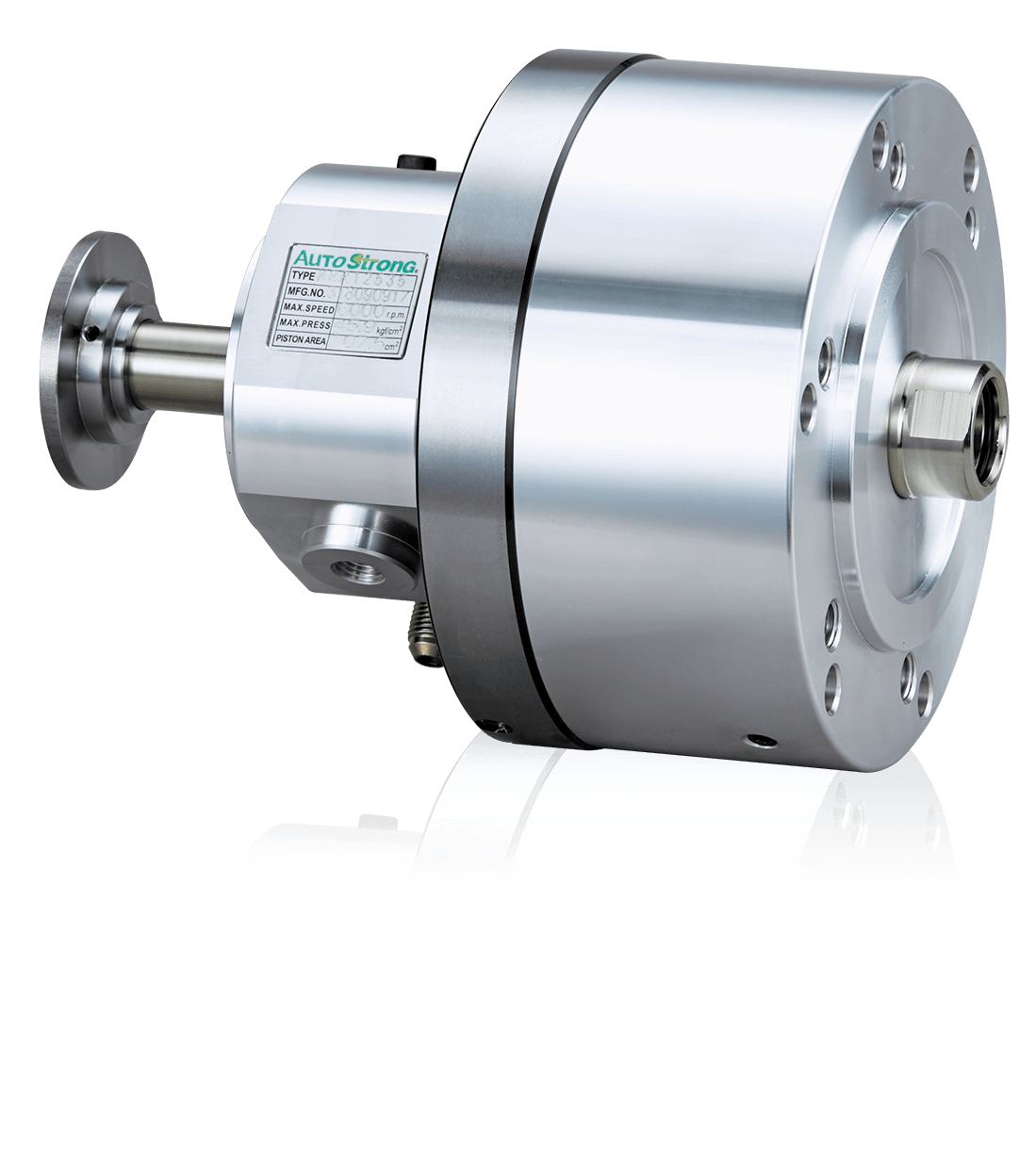

LIS AUTOMATIC CONTROLLED CO., LTD.

製品の説明 :

PJ-20V0 is a surprising design. In addition to the dead corners of the bar feeder, there are also many spaces that easy to ignore, used by customers to pile up the stuff and lose the value of use. The idea of PJ-20V0 revitalizes these spaces and is no longer limited to 2D imagination, also to evolve to the concept of 3D space. This system provides a powerful and compliant function system for users continuously. Using for continuous variable volume (pressure), saving the electricity cost and the time of the adjusted pressure. Suitable for the Swiss Lathes and gun drilling.

CHING HSYANG MACHINERY INDUSTRY CO., LTD

製品の説明 :

1. The machine combines TCT saw blade.

2. The master clamp presses from top, and clamps from two sides to

ensure stable and accurate clamping.

3. Oscillating type feeding device with ball screws, driven by servo motor,

has a feeding accurate of 0.01mm.

4. Oil mist type cooling is clean, and does not pollute the air.

5. Saw blade is protected by overload protector.

6. Touch type screen is easy for ordinary operators to use.

7. Front part and rear part of the material, and finished material are

automatically sorted out. Metal chips are removed automatically.

8. Sawing type feeding, hydraulic motor, servo motor and ball screw make

the feeding stable, and improve the tool life.

9. Three point clamped saw blade reduces sawing vibration, and promotes

the sawing blade life.

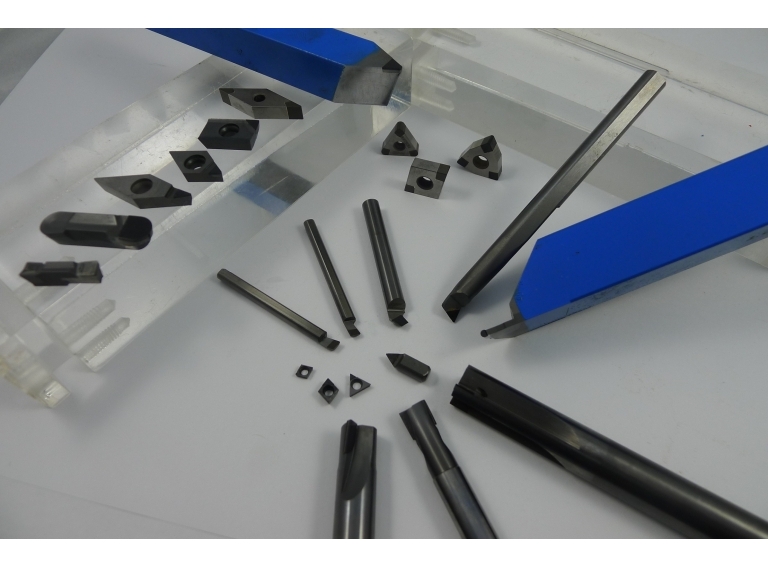

OSCAR E.D.M. COMPANY LTD.

製品の説明 :

1.X and Y sideways with manual handwheels for positioning, servo driven Z axis. COC-280 for orbit function available (option).

2.IPC industrial CPU, color LCD screen.

3.FAGOR linear scale with 0.005mm resolution (standard).

4.C7 ball screw with precisely scraped sideways, self-designed strong heat-treated FC25 casting. In combination with proper maintenance advised by OSCARMAX ensure high accuracy and reliability for decades.

5.V8 Copper and graphite special circuit to increase efficiency and minimize electrode wear-out.

6.TURBO (option) & EZ SPARK (option) - OSCARMAX selt-developed high-speed circuits help to increase efficiency and MRR of standard (TURBO) and super hard (EZ-SPARK) materials, especially for deep ribs and roughing operations.

7.Technologies for sparking steel (SKD11, P20, NAK80, STAVAX, stainless steel), aluminum, tungsten-carbide, titanium, copper, copper alloys and nickel alloys materials using graphite, copper, and tungsten-copper electrodes.

8.Memory for multiple coordinates (100 work-points).

9.DC servo drive with manual fine tuning to maintain process stability and surface integrity.

10.Remote control box for easy operation.

11.FULLY automatic programming.