展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

ADLEE POWERTRONIC CO., LTD.

製品の説明 :

Product applications:

Surface grinding machine、Internal & External grinder、CNC lathe machine、CNC milling machine, etc.

Adlee manufactures V3 class of AC spindle motor. The motion of AC induction motor makes great performance and this special design for milling machine spindle.

1. V3 class spindle motor.

2. 3 phase AC induction motor has extra low vibration performance.

3. Efficiency conforms to IEC 60034-30 IE3 standards IEC motor.

4. IEC motor specifically designs for grinding machine and low vibration applications.

5. Power range is from 1HP to 20HP.

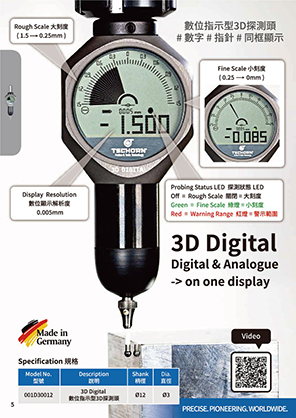

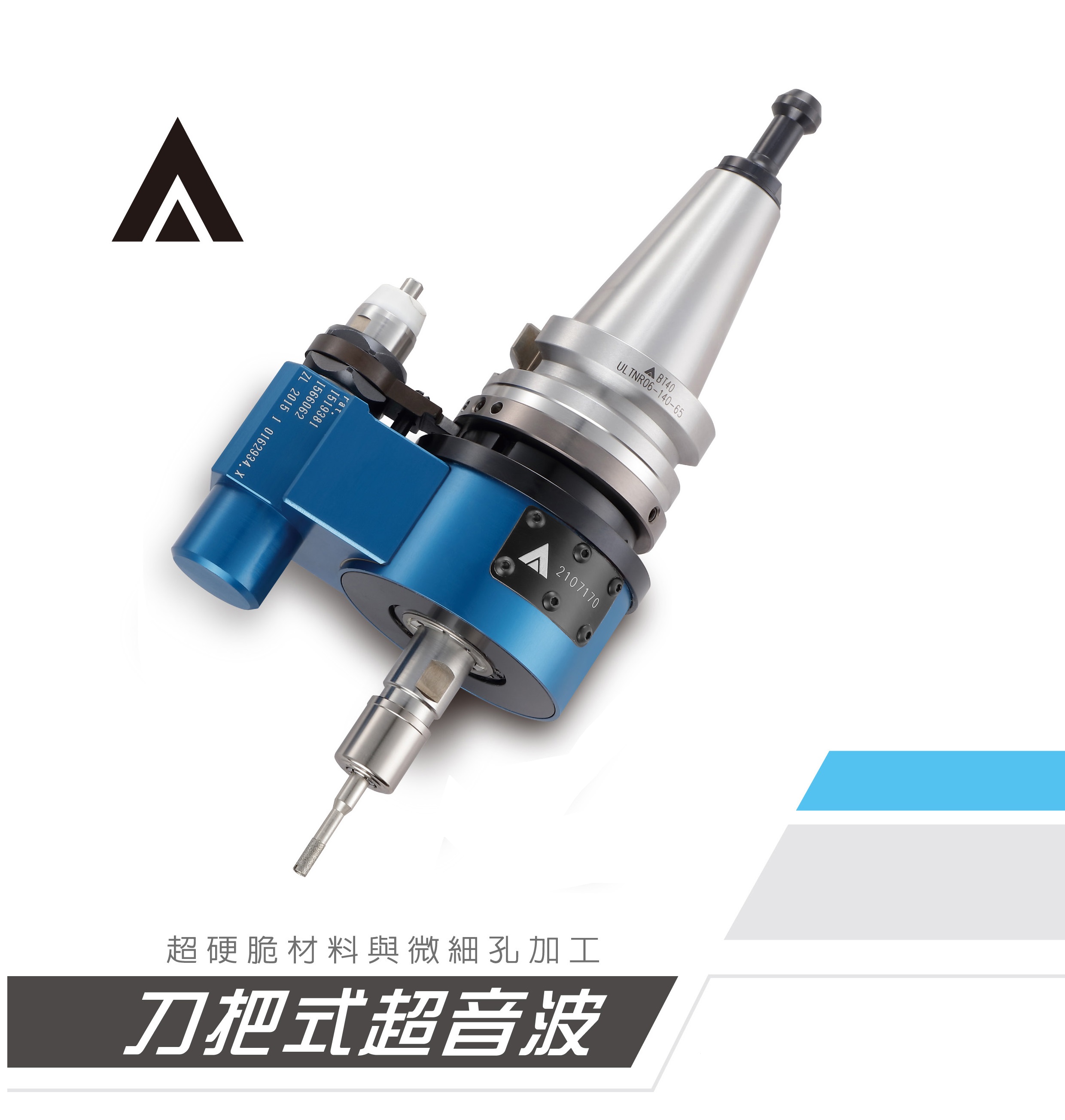

ACROW MACHINERY MFG. CO., LTD.

製品の説明 :

For Hard brittle material and micro holing drilling / Toolholder support for coolant function /

Clamping accuracy under 5 micro with the spring collets/ No need for special machine /

Easy to operate and install /

Reducing cutting resistance /

Improve surface roughness

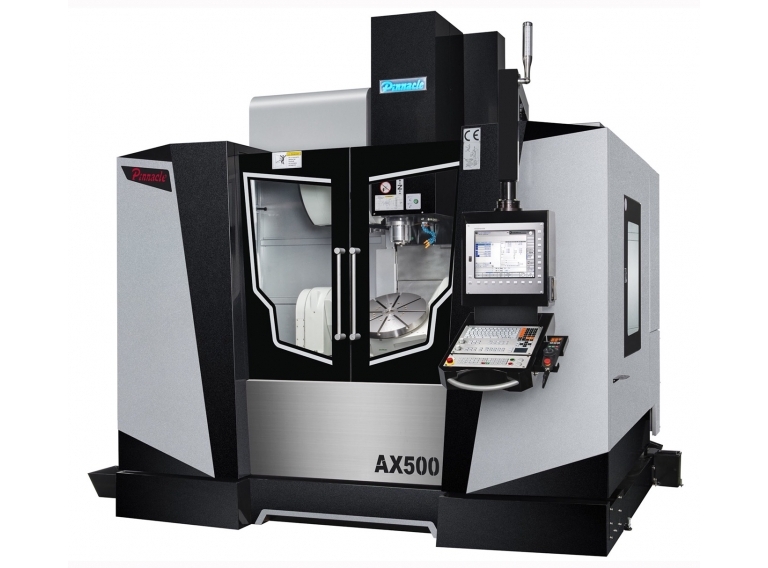

PINNACLE MACHINE TOOL CO., LTD.

製品の説明 :

嵩富AX500為高精度、高剛性5軸綜合加工機。A/C軸採用DD馬達直接驅動,最大工件尺寸可達Ø700x350mm (500公斤),A軸傾斜角度220° (-110°/+110°), C軸盤面Ø500mm可一次完成複雜、多面、曲面工件的加工,以減少加工時間。X/Y/Z標配中空油冷滾珠螺桿,以減少運作中熱變形,搭配A/C軸光學尺以達到高精度加工需求。<br />

<br />

X/Y/Z三軸採45mm滾柱型線軌,X/Z軸有6個滑塊等高剛性結構設計。採海德漢控制器TNC640,可作5軸同動加工,讓 AX500成為最符合3C、模具、醫療、航太、汽機車零件加工需求的5軸綜合加工機。<br />

SCN MACHINERY CO., LTD

製品の説明 :

深絞(深抽)成型油壓機 - SYT series<br />

<br />

Tonnage: 100 - 3000 ton<br />

Bolster Area: 800 x 700 - 4500 x 3000 mm<br />

<br />

SYT 深絞成型機 - 機身採用高張力,中鋼一級鋼板,頂座,底座,形成門型機架精加工.90°導軌八面滑合設計,滑塊上下運動,導向性好,精度好,強度高,滑合面自潤銅襯材質,導軌高週波硬化,研磨加工,永保精度不變.<br />

油壓動力系統,設計於機台後方採用管路板式集積回路設計,並附冷卻系統,效率能完全發揮,保養簡潔。<br />

油溫超過設定55度,馬達自動停止運轉,並發出警報聲,提醒操作者冷卻水異常,確保油封使用壽命<br />

配備獨立式操作控面板,吋動,下降.慢速加壓.快速上昇.等操作按鈕,前方附有緊急停止按鈕,操作容易安全,由壓力表設定出力大小、行程位置調整於微動開關設定。<br />

<br />

符合ISO9001:2015認證