展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

RAISE PRECISION CO., LTD.

製品の説明 :

CAPTRON, pioneer of the first capacitive two-hand control system, ensure the highest safety category according to (Cat. 4) and PL e (DIN EN ISO 13849-1). The capacitive "safeCAP" two-hand control allows heavy machinery and systems in automated production plants, such as presses and punches, to be controlled safely and without pressure.

To start the machine the user simultaneously presses two capacitive buttons which are connected to a safety relay. Incorrect or inattentive control using just one hand or with another part of the body is detected by the system and the machine is not started.

CAPTRON supplies the safeCAP two-hand control with additional safety elements such as the Protector or the control desk for tabletop installation. These combinations enhance protection and are certified to DIN EN 574. The dynamically switching SENSORswitches detect interference factors such as dirt, dust or foreign bodies. The switches can be actuated using disposable or work gloves, however.

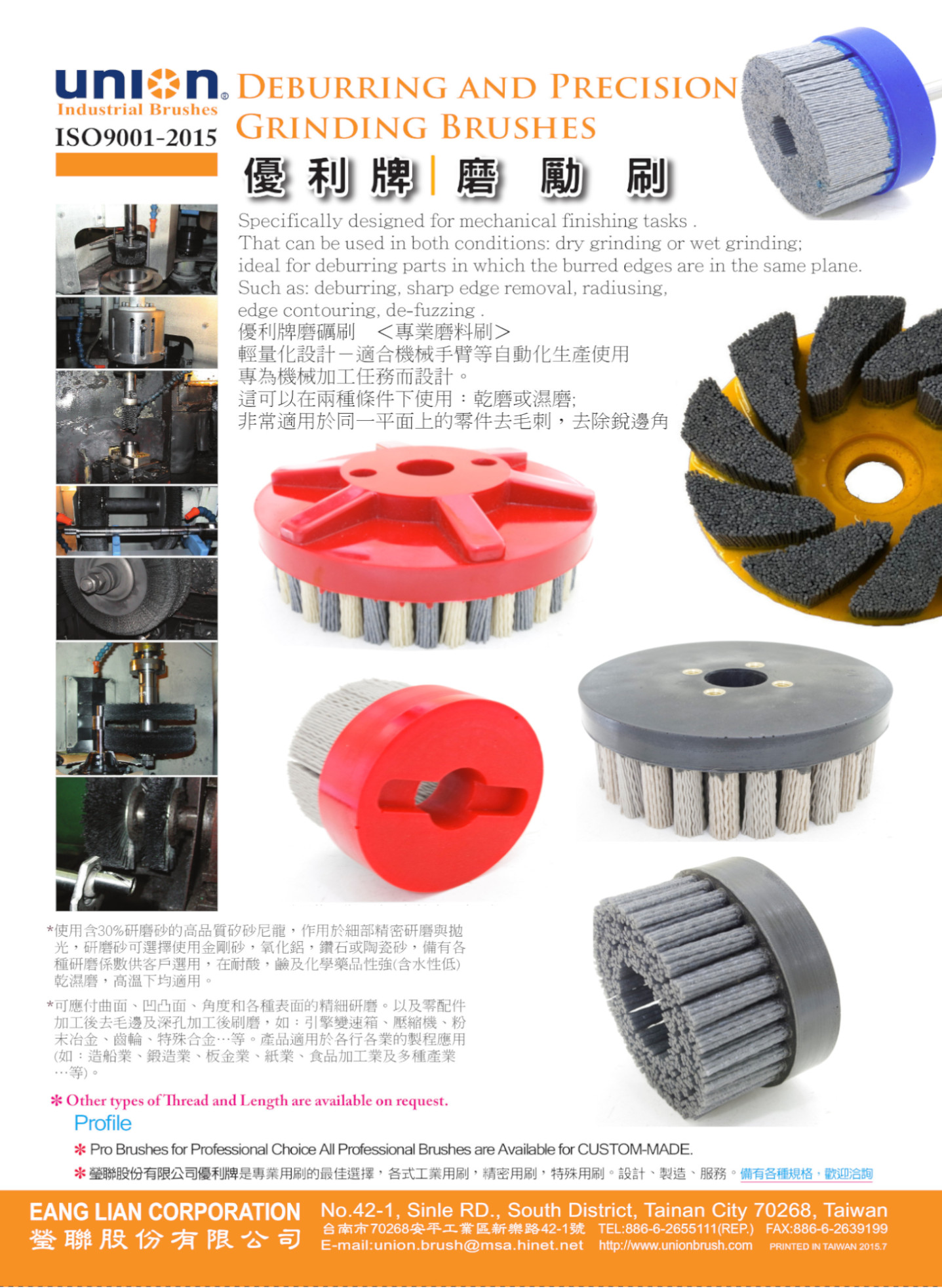

EANG LIAN CORPORATION

製品の説明 :

Professional Abrasive Brushes-Specifically designed for mechanical finishing tasks .

Specifically designed for mechanical finishing tasks .

That can be used in both conditions: dry grinding or wet grinding;

ideal for deburring parts in which the burred edges are in the same plane. Such as: deburring, sharp edge removal, radiusing,

edge contouring, de-fuzzing .

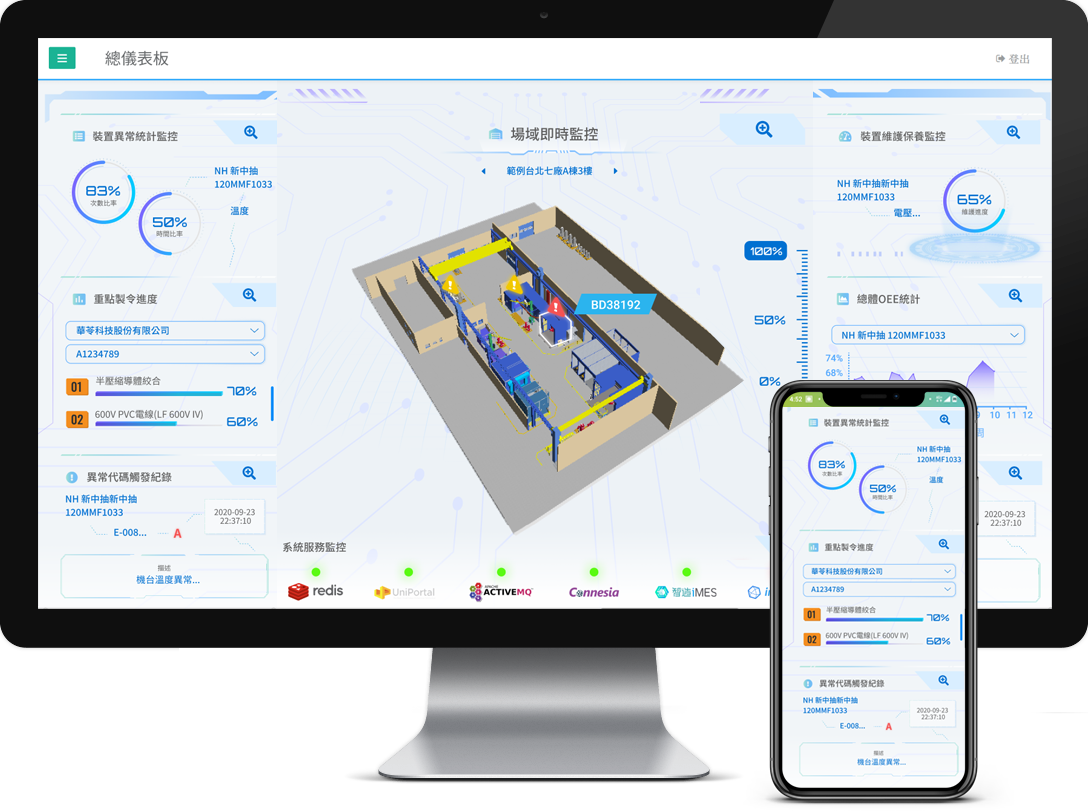

Administration for Digital Industries, moda

製品の説明 :

iMES's real-time Internet of Things and monitoring reports gradually achieve smart manufacturing remote monitoring, providing each manufacturing customer with six major capabilities, including real-time collection of production data, working hours management, exception notification, intelligent management of production lines, optimization of production schedules, etc. Intelligent production applications realize automated and efficient interconnected factories.

1. Arrange optimal production schedule.

2. Generate ERP work orders.

3. Automatically manage machine recipe parameters.

4. Two-way real-time control of the machine device.

5. Manage the triggering rules for subsequent tasks on the machine.

6. Automation machine completion report information.

GUEY CHERNG TRADING CO., LTD.

製品の説明 :

SIMPLE

Tool is clamped in 8 seconds by pushing

only one single button.

SAFE

No heat up – high clamping force. Excellent vibration dampening.

HIGH PRECISION

Toolholder runout TIR ≤ 1 μm

Total system runout TIR ≤3 µm at 3 x D.

powRgrip®

The tool clamping system of today and the future.

LEADWELL CNC MACHINES MFG., CORP.

製品の説明 :

LTC-35LY is a high-performance CNC lathe, suitable for machining various complex parts, especially parts for the automotive industry. It has the following advantages:

The bed structure is very rigid and able to withstand large cutting forces. The spindle and servo motor are high-speed and high-precision, able to quickly and accurately complete the cutting and drilling actions. The Y-axis function allows it to add another moving direction perpendicular to the spindle, in addition to the X-axis and Z-axis, which enables it to achieve more machining angles and shapes, improving the

flexibility and accuracy of machining. The CNC system supports various CNC programs, making it easy for users to design and operate according to different workpieces, reducing errors and waste. It has excellent performance and can improve the quality and efficiency of products, reduce costs and time, and bring more value and competitiveness to users.

Max. swing: 800mm

Max. turning diameter: 430mm

Max. turning length: 1530mm

Bar capacity: 115mm

X-axis travel: 215+25mm

Z-axis travel: 1600mm

Y-axis travel: +100/-80mm

Spindle speed: 2000rpm

Spindle nose: A2-11

Chuck size: 15"

Number of tool stations: 12T

HABOR PRECISION INC.

製品の説明 :

HABOR_ HIG DC Inverter Cooler_ High energy-saving X Low-carbon emission

Upgraded with new generation refrigerant_ R513A which is Low-GWP to reduce the warming influence, Habor HIG series is the best partner for green machine tools.

Habor HIG series is a DC inverter cooler integrated technologies of smart IoT, energy-saving, high-accuracy control, equipped with Ethernet Communication protocol for remote setting and real time monitoring, intelligent management of predictive maintenance and status detection.

Thanks to speed control and frequency conversion technology, HIG series can save energy cost up to 60%. In 2024, we announced new coolers which uses LOW-GWP refrigerant R513A on the base of use less refrigerant system to reduce carbon emission up to 70% .

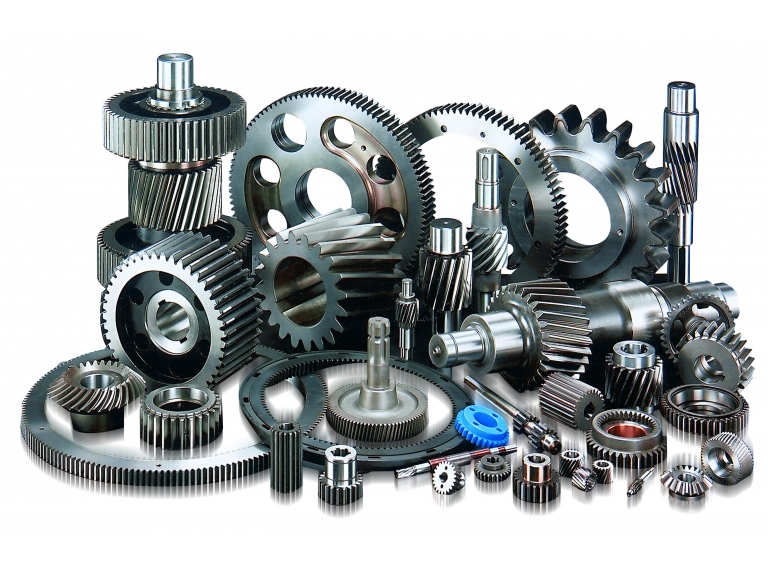

Habor provides wide range of high precision temperature control system to machining process, such like cooling for spindles, coolant, linear motors, ball screw, gear box, hydraulic systems….etc.

Going forward Net Zero by 2050, except DC inverter cooler unit, Habor also provides various solutions to help users to save cost of factory electrical consumption. For more information, you are welcome to our booth in TMTS2024.

Habor Booth No. P0114, 1F Hall 2