展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

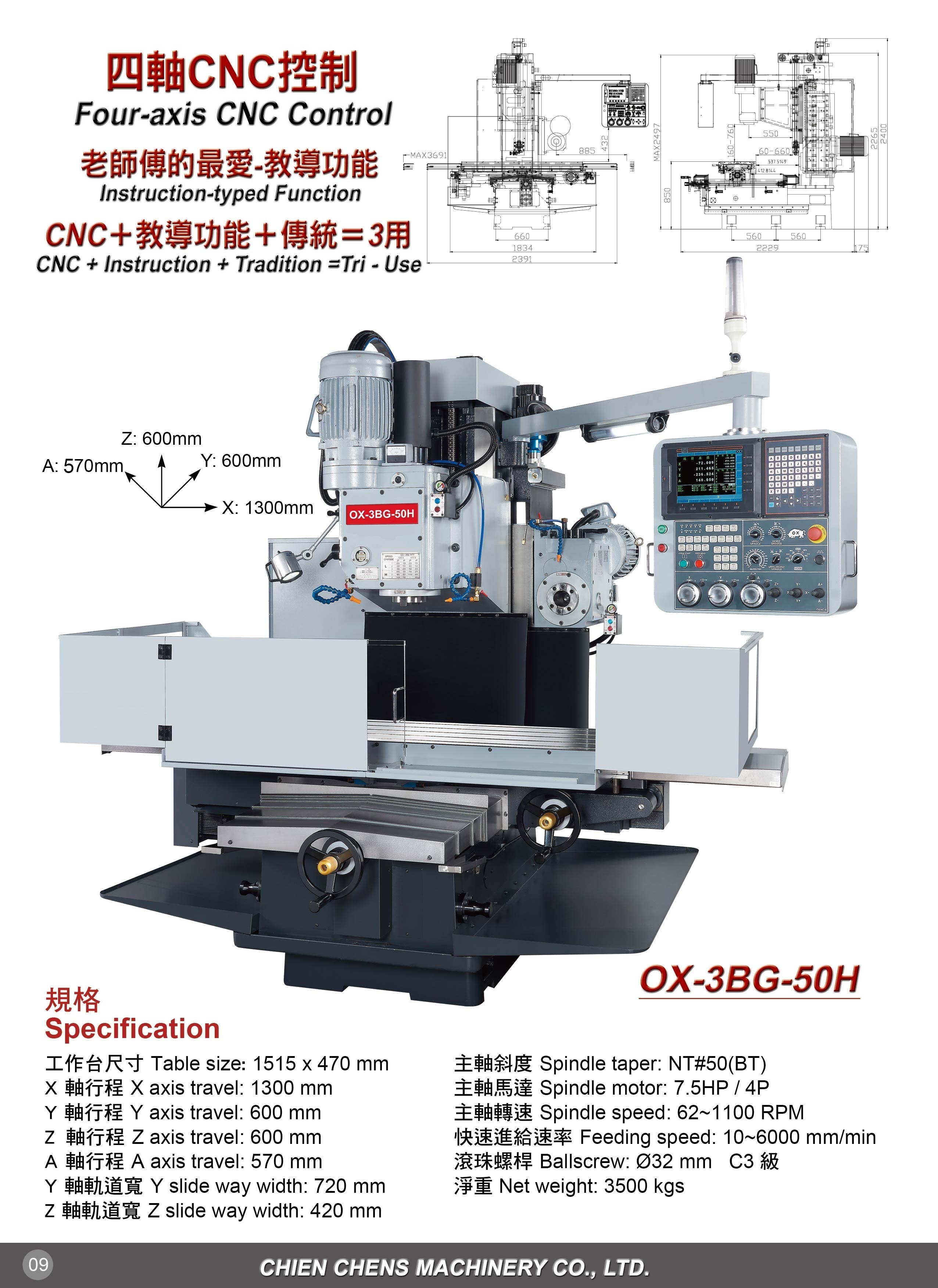

CHIEN CHENS MACHINERY CO., LTD.

製品の説明 :

Specification

Table size: 1515 x 470 mm

Longitudinal travel: 1300 mm

Cross travel: 600 mm

Y slide way width: 720 mm

Z Slide high: MAX 760 mm

Z Slide way width: 420 mm

Spindle taper: NT#50(BT)

Spindle motor: 7.5HP / 2P

Spindle speed: 62~1100 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø32 mm C5

Net weight: 3200 kgs

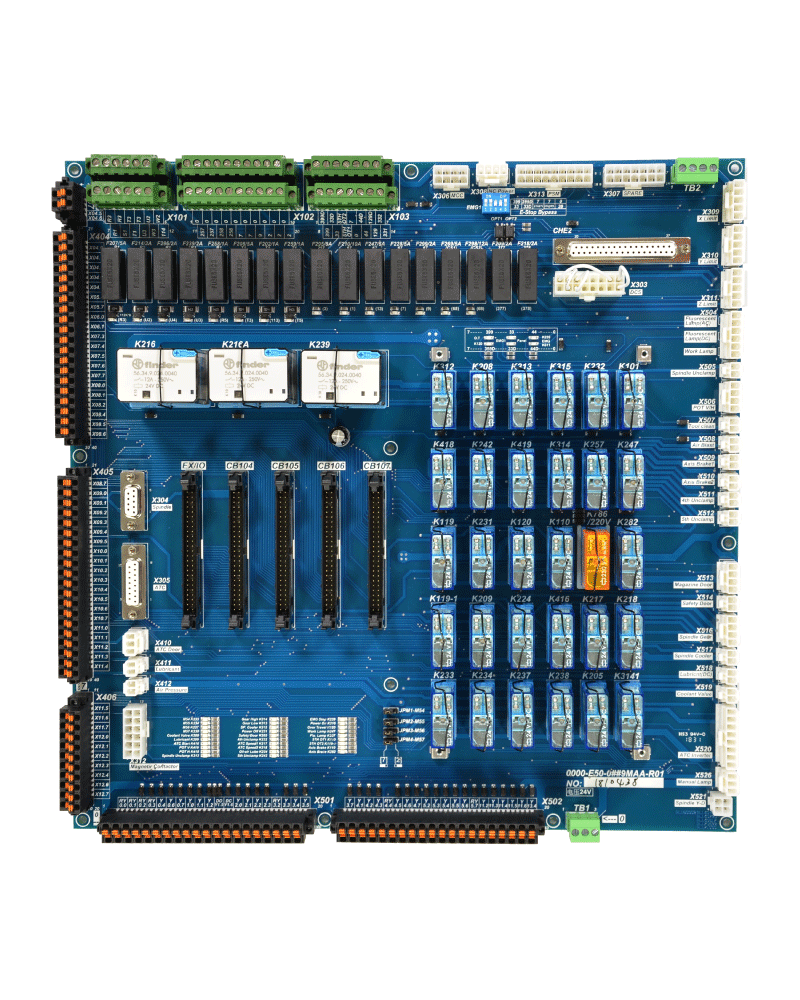

YEU-LIAN ELECTRONICS CO., LTD.

製品の説明 :

OEM/ODM circuit board combined adapter board, relay board, patch board and I/O board into one piece - all optimized to customers' needs. The PCB circuit board can customize various controllers such as FANUC, MITSUBISHI, SIEMENS, FAGOR, HEIDENHAIN and industrial types. Apply to CNC machines like lathes, milling machines, turning, multitasking machines, machine tools or industrial machinery.

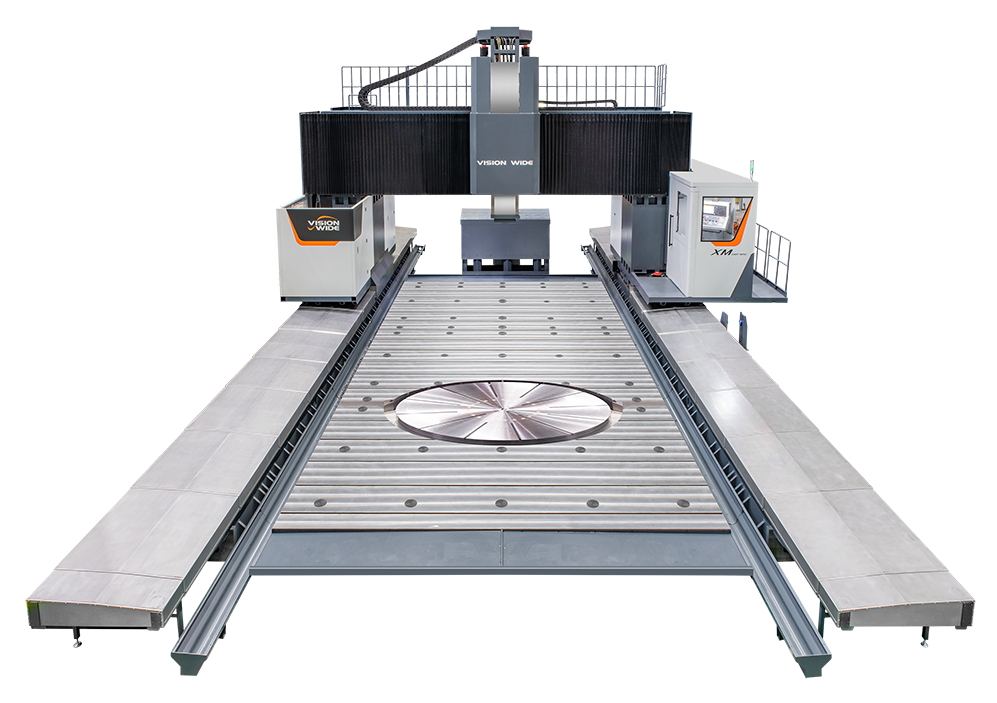

VISION WIDE TECH CO., LTD.

製品の説明 :

High Performance and Wide Application

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

• High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

• Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

• Fully automatic multi-face machining: This moving column machining center can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

• Milling and turning compound multitask: This moving column cnc milling machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.

AUTOGRIP MACHINERY CO., LTD.

製品の説明 :

Brand new upgrade! Introducing the Grip Force Sensor (GFS-100) with advanced gripping technology. Bluetooth 5.0 ensures exceptional wireless connectivity, making your operations smoother. Convenient Type-C charging interface for easy charging, providing continuous power for your work. The high-performance lithium battery offers extended battery life, eliminating concerns about power shortage during work and allowing you to focus on your tasks. GFS-100 supports both Android and iOS systems, ensuring seamless compatibility for a user-friendly experience. With the flexibility to configure as a 2-claw or 3-claw operation based on your actual needs, it provides greater operational versatility. Upgrade your work experience with GFS-100, showcasing the convenience and efficiency of cutting-edge technology.

YING HAN TECHNOLOGY CO., LTD.

製品の説明 :

YTL8320G

CNC computer lathe and portal robot arm

Machine features

- Automated process control

- Mass production of extremely precise workpieces

- Visual programming made easy

- Efficient process intelligence

Machine specifications

- 8-inch spindle chuck

- 45 degree slant back bed

- Z/X axis travel: 320/185mm

- Max. load of robotic arm is 4kg

- 10 station of storage capacity

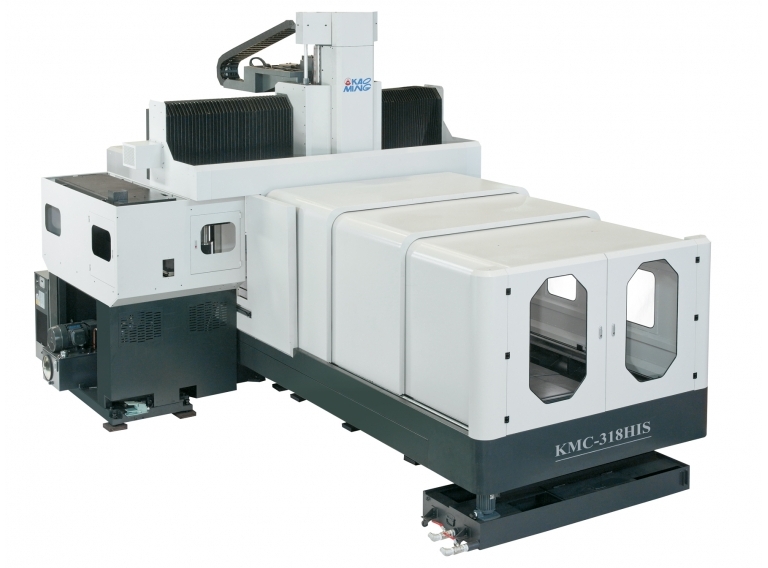

KAO MING MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

1. 門寬2.1米以下,底座採用雙線軌設計;門寬2.3米以上底座採用三線軌設計,並具有硬軌之高剛性結構,Z軸行程可達850mm。<br />

<br />

2. 三軸均配備大型滾柱式線性導軌;剛性與速度兼顧。<br />

<br />

3. Y軸採用階梯式導軌設計,上軌與下軌段差225mm的特殊設計,使主軸頭不易前傾,同時分擔了部份Y軸失利於立柱的推力,使主軸頭在重切削負荷時,非常穩定;並以垂直方式偏置排列,確保最佳結構剛性。<br />

<br />

4. 主軸以直結式傳動,減少軸不對心引起的振動,提高切削性能與精度。<br />

<br />

5. 最佳主軸頭中心對稱式設計,減少熱變位影響,確保主軸精度。<br />

<br />

6. 利用有限元素分析(FEA)先進實務觀念,設計出最佳化底座立柱及橫樑等主要結構剛性。<br />

<br />

7. 三軸使用高精度並施以預壓及預拉之滾珠導螺桿;X軸採中空設計並通過冷卻油,且螺桿兩端之稱軸承外環,有空氣冷卻之特殊設計,減少熱變形,確保最佳之定位精度。<br />

<br />

8. Z軸油壓平衡配重;在Z軸上使用兩支油壓缸抵消主軸頭重量,確保加工時的穩定性。<br />