展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

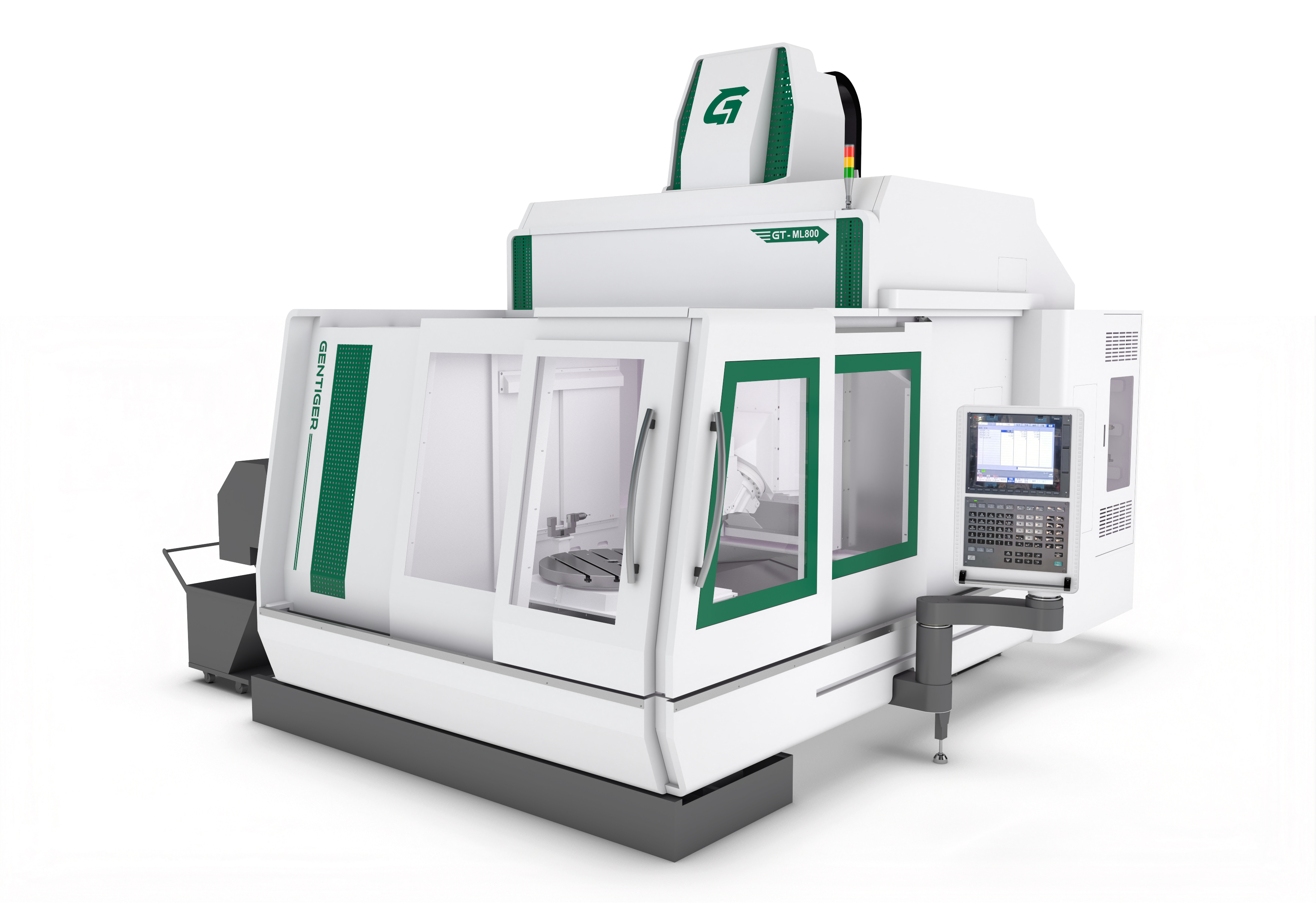

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

• Closed-type double-column structure, it increases structure dramatically increases the structural rigidity of the machine and maintains extraordinary stability at all times.

• Roller-type linear guideway on three axes, it achieves high loading resistance, high rigidity, long service life, low thermal growth, and low noise.

• Three linear guideways on the Y axis, it provides more stable support for the spindle head, which contributes to upgraded stability in machining.

• The 45° vertical horizontal swiveling head is applicable for both vertical and horizontal machining, increasing flexibility in machining applications.

KO-YAN PRECISE MACHINERY CO.,LTD

製品の説明 :

GJ-400 series from COMIRK combines internal grinding and cylindrical grinding in a single machine. Multiple face grinding can be accomplished with one setup for the work-piece. This machine not only saves considerable amount on machine investment costs and labor costs, but it also features dramatically upgrade for better machining efficiency and machining accuracy.

Machine Features

-Various speed of spindles selection allows for the highest grinding efficiency

-Double wheel spindles exhibit high efficiency internal and external grinding

-Internal, external, end face and tapered face can all be ground in one process

-Highly rigid machine structure ensures the best possible stability during grinding

-X, Y, Z axes are all mounted with high precision linear guide-ways.

-This machine is equipped with a FANUC CNC controller

-Multi-face grinding requires only one setup for the work-piece.

-Non-circular grinding function is available (Optional)

-Fully enclosed splash-guard

CHUAN TAI HYDRAULIC MACHINERY CO., LTD.

製品の説明 :

The oil return filter is mainly installed on the oil return line of the hydraulic system. Various impurities such as abrasive particles generated during the work of various hydraulic components can be blocked by setting the oil return line to filter and avoid returning to the tank again.

MING YANG MACHINERY CO., LTD.

製品の説明 :

This multi-tasking turning center is an advanced machine designed to process precision complex parts in one setup.

Power & Versatility: It has Double Spindles, a VDI/BMT 12 station Turret and a 2nd Y-Axis for back machining with 14 tools for a total capacity of up to 38 tools. This solution with superimposed cutting is a powerful combination of precision and two Y-axes for machining of complex workpieces with extremely fast cycle times.

Front Machining: BMT45 12-Stations, Up to 24 tools, 7.5/11 kW Spindle Power, 55 mm Through Hole.

Back Machining: Gang Tools Slide: 14 Tools, 3 Cross Live Tools, 3 Face Live Tools, 3 OD & 5 ID Tools.

ENSINGER ASIA HOLDING PTE. LTD. TAIWAN BRANCH

製品の説明 :

TECAPET PET polyester from Ensinger is specially formulated to provide improved toughness, and enhanced machinability. This PET polyester also offers excellent sliding and wear properties, and a low coefficent of friction. TECAPET's superior chemical resistance, non staining characteristics, and distinct lack of centerline porosity, makes it a desirable material for a variety of applications especially in the food industry that might involve solvents, cleaning chemicals, or direct food contact.

JIN YEAR PRECISION CO., LTD.

製品の説明 :

Features:

1. This machine has the "CE safety authentication".

2. Operates is fast and simple.The quality is stable.

3. Point Angle 90°~135°.(Generally is suitable 118°)

4. Chisel edge grinding. Can adjusting by your demand.(Generally is suitable 0.7mm)

5. It's the first to research and development "up to down" swinging grinding way.The finished drill is sharpest, and the most durable.

Our company new researches and develops, swing the drill grinding from up to down, very sharp.

Generally rotate the drill grind left to right, it's blunt.

HAI JU TRADING CO., LTD.

製品の説明 :

High-strength connection and maximum sealing

Can you imagine high-quality products without screw connections?

Modern technology cannot do without them as detachable joints. In the industrial

sector, fluid technology, pneumatics and sealing technology are among the fields of

application. In those sectors, often additional functions such as sealing, insulation or

reuse of bolts are required – only to mention a few.

One classic example are adjusting screws on hydraulic components, steering boxes

and fuel injection pumps. For those applications, high-strength screw connections

with reusable bolts and sealing against leakage are essential. We provide the solution

that fulfils those high requirements: the SEAL LOCK® sealing nut. It prevents any

unwanted leaking of gaseous or liquid media. The SEAL LOCK® ring integrated on

the nut helps to achieve reliable sealing inside the thread without the use of

additional elements. It is reliable in two ways because it seals under the head and

inside the thread. Not to mention the easy installation.

The following figures show conventional solutions on the one hand and the

SEAL LOCK® sealing nut on the other hand.