展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

Administration for Digital Industries, moda

製品の説明 :

Robotiive, developed by IsCoolLab, is a Robotic process automation (RPA) solution that utilizes patented AI computer vision technology to achieve cross-platform, cross-system, cross-machine, and remote desktop data extraction, integration and automation. It is the only RPA system in the market that integrates both manufacturing and office settings.

Using Robotiive, corporations can enhance productivity and efficiency but also substantially reduce human resource and operational costs. Additionally, its high scalability allows businesses to customize settings according to their own needs, providing their departments with a 24/7 digital workforce.

R PLUS TECHNOLOGY CO., LTD

製品の説明 :

1.Effectively and quickly remove water and particles

2.Easy replacement of 40μm and 5μm filter cartridges

3.Simple and accurate pressure adjustment

4.Do not turn off the air supply and stop refueling

5.Fine oil spray to ensure effective protection and extend the life of parts

6.Acid and alkali resistant cups and aluminum cups for use in volatile solvents in organic solvents and chemicals in the surrounding environment

WEXTEN PRECISE INDUSTRIES CO., LTD.

製品の説明 :

■ Maintained the constant oil temperature in order to prevent process-ing precision-losing.

■ Kept oil viscosity and avoid oil deterioration to stable spindle working.

■ With the temperature control panel to avoid thermal expansion.

■ Built-in failure-detection system that connects to control panel in order to warn users and prevent further damage to machine.

■ Filling high-efficiency environmental refrigerant, without pollution.

KINGYOUP ENTERPRISES CO., LTD.

製品の説明 :

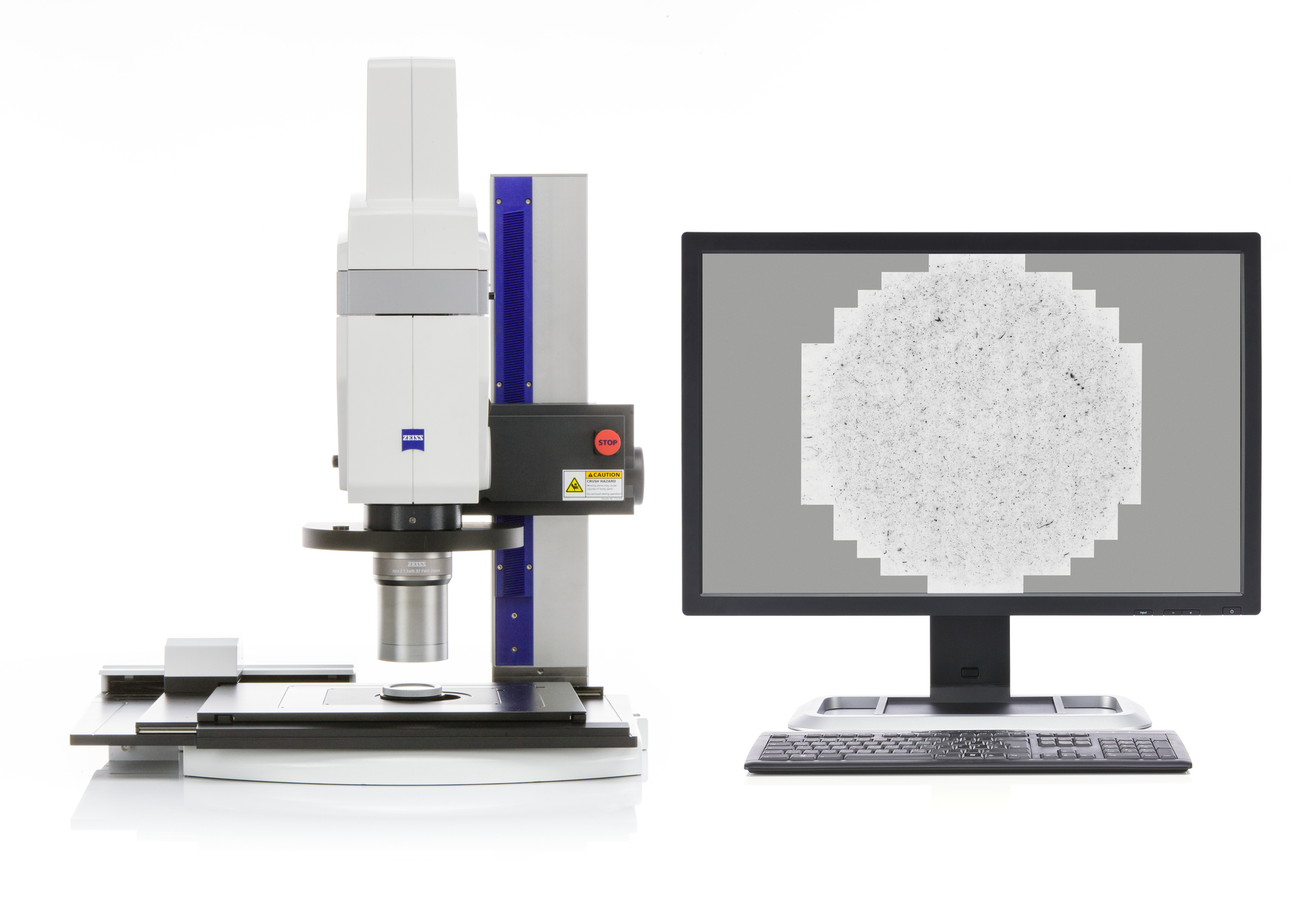

The INNOVATEST hardness tester covers various testing methods such as Rockwell, Vickers, Brinell, and Knoop, and all products comply with ISO and ASTM standards. In ISO 17025 accredited laboratories, you can confidently use the calibrated and certified INNOVATEST hardness tester. We have already provided advanced material testing solutions to numerous international machinery, aerospace, automotive manufacturers, and research institutions.

The INNOVATEST multifunctional hardness tester offers an extensive range of testing forces and methods, providing users with a user-friendly and convenient testing experience. The equipment is suitable for a wide range of material testing and applications.

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

製品の説明 :

NFX400A is designed especially for small, complex high-quality parts mainly for aerospace, automotive, medical, job shop and die & mold applications

■ Extra wide column and base design to ensure best support and cutting rigidity.

■ Increased tool life by cutting with belly and edge of the tool

■ Reduce fixture error and improve workpiece loading and uploading time

■ Greatly reduced non-cutting or setup waiting time

■ Saves manufacturing cost with reduced fixture and electrode costs.

DKSH Taiwan Ltd.

製品の説明 :

PC F series is designed to produce maximum distillate quality with minimum capital and operating costs. Each model is a compact skid-mounted unit, simple, safe and easy to move. Control is by a PLC, including the functions of feed and discharge, therefore allowing automatic operation and minimum supervision. All models are designed for continuous operation, 24h/day, and require just electrical supply and compressed air.

PC F series evaporators operate in a high vacuum condition, with the boiling chamber pressure set at 5-6 kPa (absolute vacuum), in order to save the thermal energy produced by the heat pump. In this way the boiling temperature of the wastewater is approximately 40°C (104°F) and typical phenomena (scaling, precipitation, corrosion) which may reduce the performance are either eliminated or considerably reduced.

From 0,7 to 24 m3/day – 0.13 – 4.4 US gpm of distillate

Dramatic reduction of volumes and disposal costs

Water reuse and matter recovery

KAO FONG MACHINERY CO., LTD.

製品の説明 :

KG series gantry five-sided machining center is able to choose to carry all kinds of automatic additional head (90゜angle milling head, universal head, extension head, speed-up extension head ... etc.) auto tool changer. Standard verticaland horizontal tool changer magazine tool with optional multi-head library for automatic head exchange. Angle head part has 5° division curved tooth with standard high precision, and are able to select 1/2.5°division or watering function at the center. KG5A series bridge crane five-axis machining center is mainly designed for the processing demand on medium and large weight workpieceparts, with world-class high-quality five-axis manufacturing technology to complete the five-axis processing, it synchronously completes vertical, horizontal and a variety of free angle of processings, which substantially increases the processing efficiency. Floor-type workbench with super load capacity, up to 2.5 tonsweight per square meter. Adopting HSK-A63 24,000 rpm high-speed spindle or the heavy cutting spindlewithHSK-A100 10,000 rpm high-torque output depends on different maching applications, which greatly improves the processing efficiency of large workpiece, and fully meets the processing needs of different industries.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

X axis travel:

Single movement: 1125 mm (44" )inch

Dual movement: 560 mm (22") inch

YZ axis travel 700x500 mm (28"x20") inch

Work table: 1850x850 mm (73"x33") inch

Max. Workpiece: 2800x1400x700 mm (110"x55"x28") inch

Max. Workpiece weight: 5800 kg

Max. electrode weight: 400 kg

Machine net weight:8350 kg

Oil level: 110-550 mm (4"-22") inch

Packing size(LxWxH): 5430x4600x3090 mm (214"x181"x122") inch

Work Table to platen: 700-1200 mm (28"-47") inch

Filter: 4

Paper filter:8

Capacity:3400 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.