展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

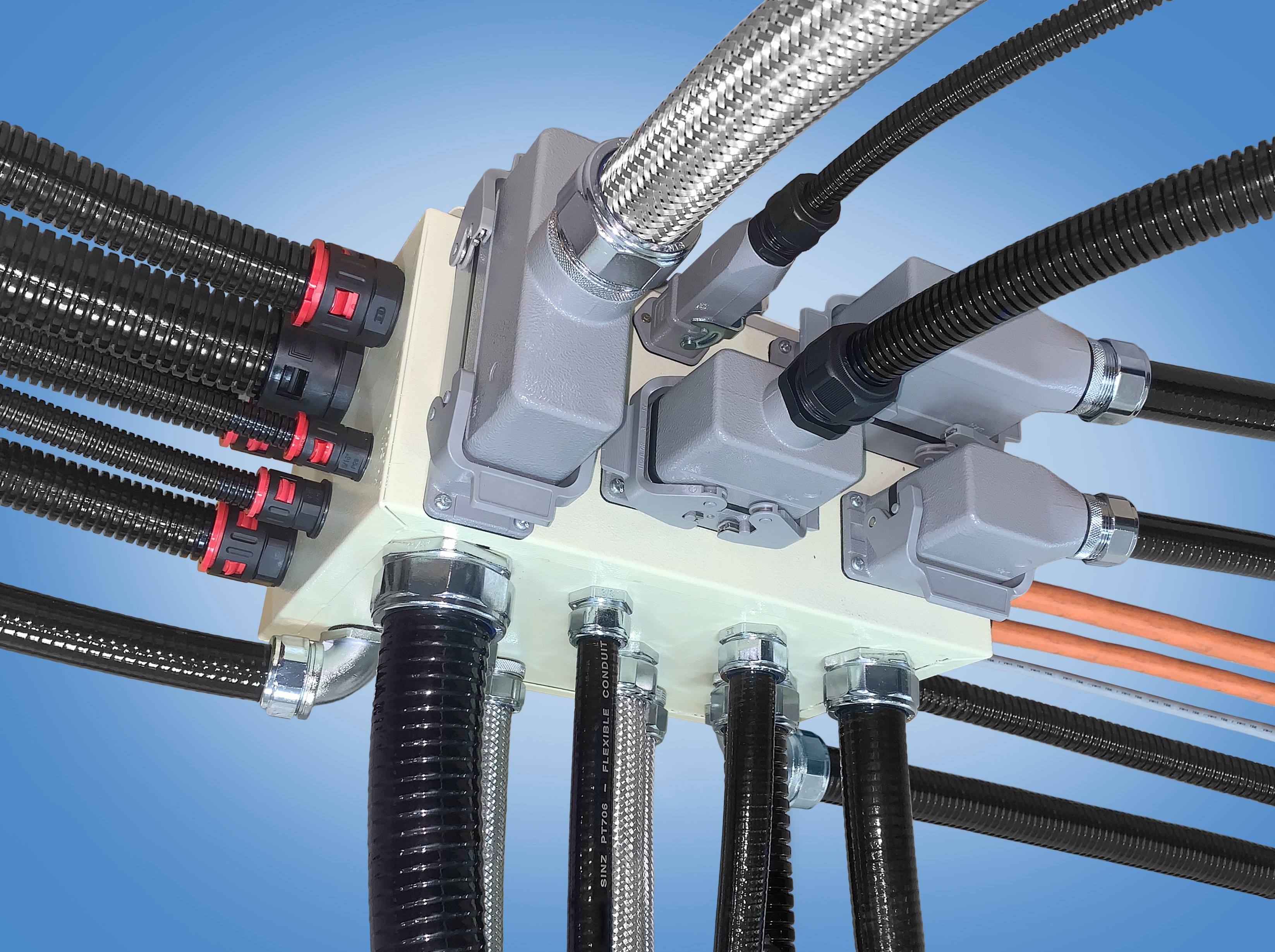

SING CHIUN ENTERPRISE CO.,LTD.

製品の説明 :

Connector products include:

(1) LIQUID-TIGHT CONNECTORS

(2) COMBINATION CONNECTORS

(3) POLYESTER LIQUID-TIGHT CONNECTORS

(4) THREAD PG & M CONNECTORS ADAPTER (Metal)

(5) MS-PLUG/CONNECTORS ADAPTER (Metal)

(6) SQUEEZE LIQUID-TIGHT CONNECTORS(Hydraulic

clamp is not loose)

(7) METAL CABLE GLAND

(8) POLYESTER CABLE GLAND

(9) MS-PLUG/CONNECTORS ADAPTER (Polyester)

(10) METAL 90° ANGLE-SHAPED WALL-MOUNTED

OUTLET SOCKET

(11) MTR METAL ADAPTER

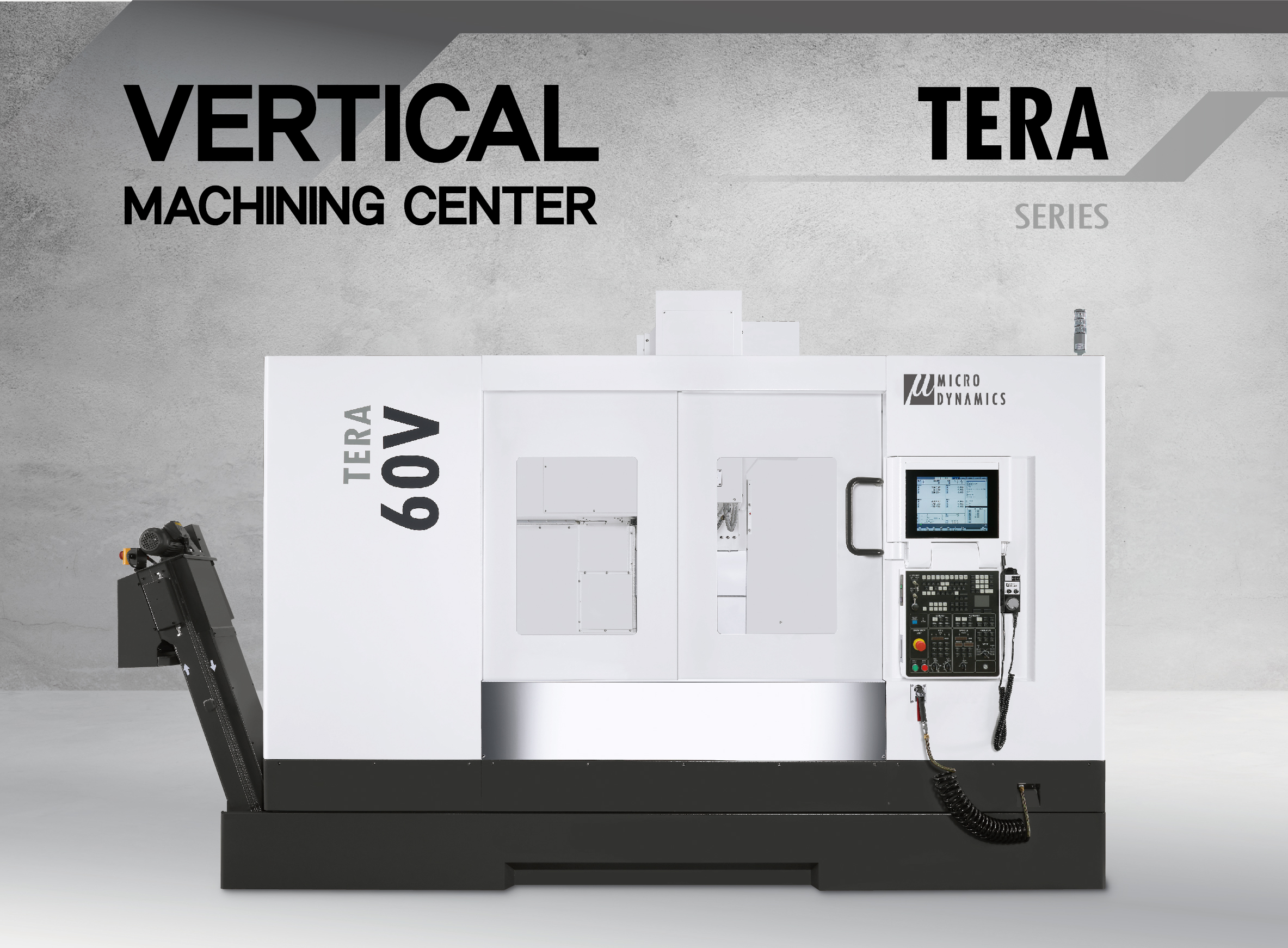

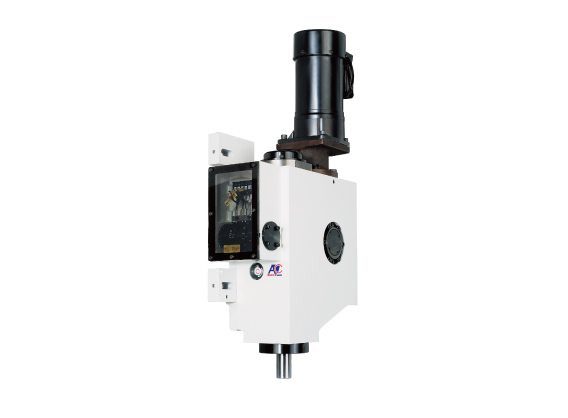

INNOSERV FA INC. TAIWAN BRANCH (BVI)

製品の説明 :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI

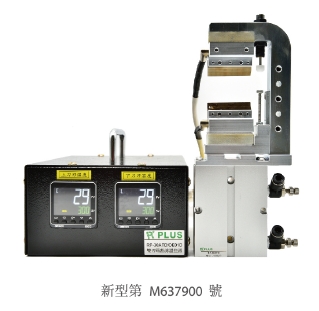

R PLUS TECHNOLOGY CO., LTD

製品の説明 :

Rplus pneumatic thermal cutters are designed for plastic molding and specified configuration. A designed pair of thermal knifes with a suitable heating rate, the unique design will reduce the heating time and reach the setting temperature in few seconds. The shearing is driven by a dual rod cylinder with 0.15~1Mpa range pressure.

Knifes are made by alloy special steel with heat-treatment. The heating capacity is 150W within 8mmx35mm heating bars , the range is 60~350C. The dual rod cylinder drives the thermal knifes will lead to a stable shearing effect, as well as higher efficiency, reduce the loss, faster shearing and depends on different type of plastic can be set variable heating temperature.

For modern manufacturing, we can integrate on a robot arm and automatically processing line.

Examples of widely application as head lamp of automobile,optical lens, acrylic products and Polycarbonate,etc. We forward to offer a safer , easier and efficiency tools.

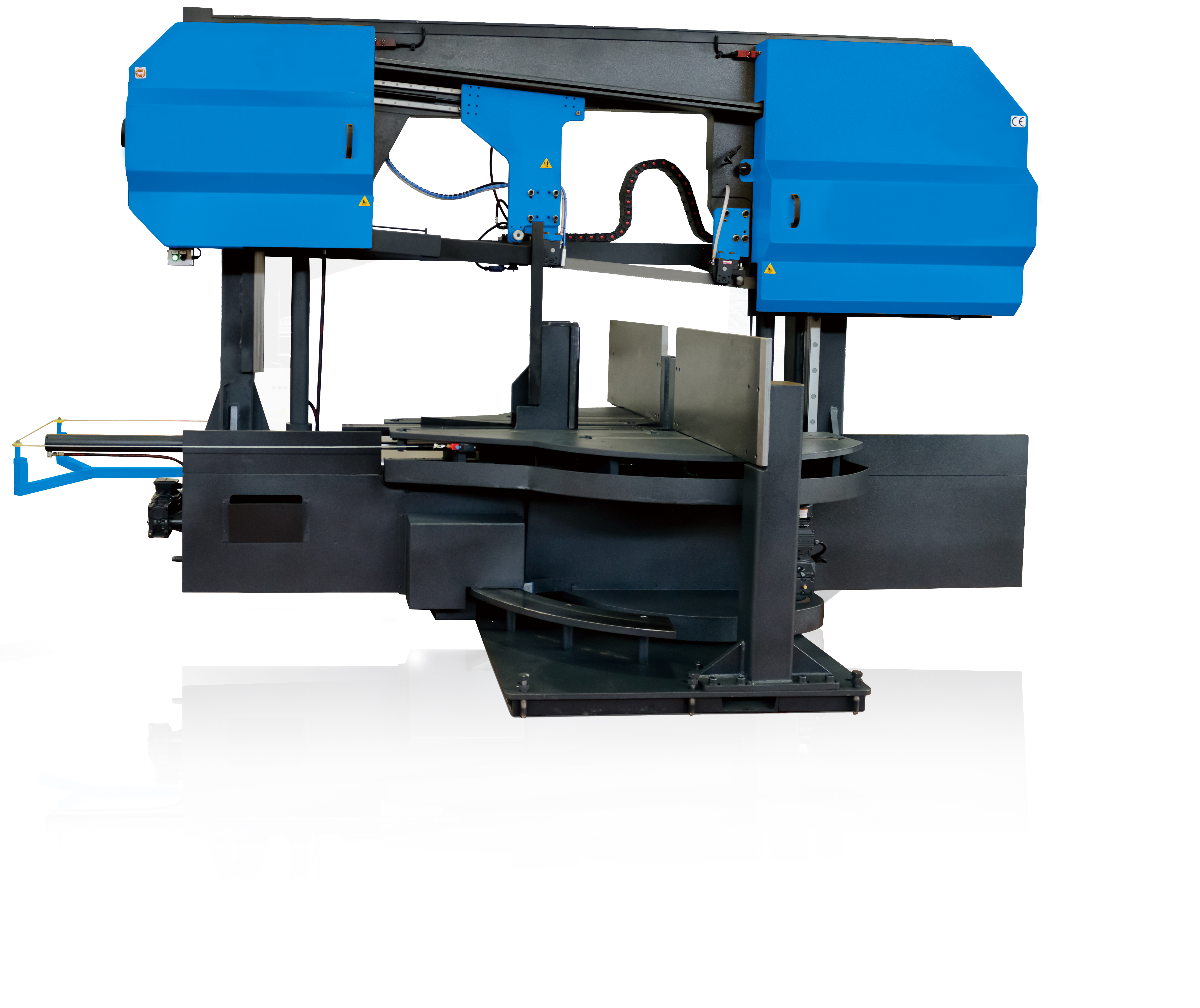

CHING HSYANG MACHINERY INDUSTRY CO., LTD

製品の説明 :

1. The machine combines TCT saw blade.

2. The master clamp presses from top, and clamps from two sides to

ensure stable and accurate clamping.

3. Oscillating type feeding device with ball screws, driven by servo motor,

has a feeding accurate of 0.01mm.

4. Oil mist type cooling is clean, and does not pollute the air.

5. Saw blade is protected by overload protector.

6. Touch type screen is easy for ordinary operators to use.

7. Front part and rear part of the material, and finished material are

automatically sorted out. Metal chips are removed automatically.

8. Sawing type feeding, hydraulic motor, servo motor and ball screw make

the feeding stable, and improve the tool life.

9. Three point clamped saw blade reduces sawing vibration, and promotes

the sawing blade life.

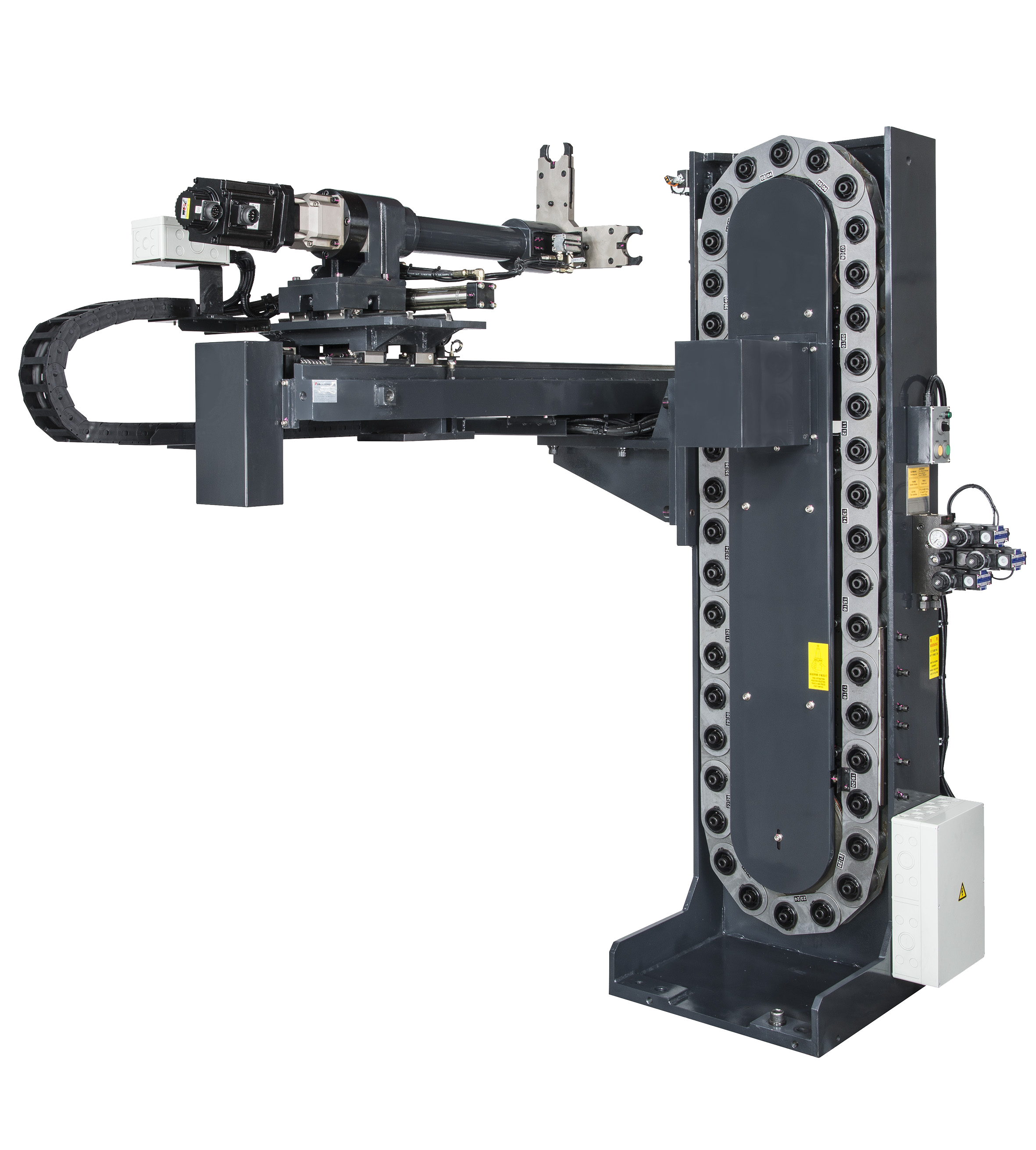

GIFU ENTERPRISE CO., LTD.

製品の説明 :

Applicable Specification:

BT40/CAT40/DIN40/HSK63/CAPTO6

Applicable Model:

Multi-Tasking Machines

1.L-shape arm allows speedy tool changing with short sequence. Besides, low swing loading makes long product service life.

2.The main chain wheel is driven by servo motor, which achieves accurate positioning, fast tool selection and multi-tasking tool management.

3.The long-distance movement is driven by servo motor, which achieves fast and accurate positioning.

4.Expandable tool storage.

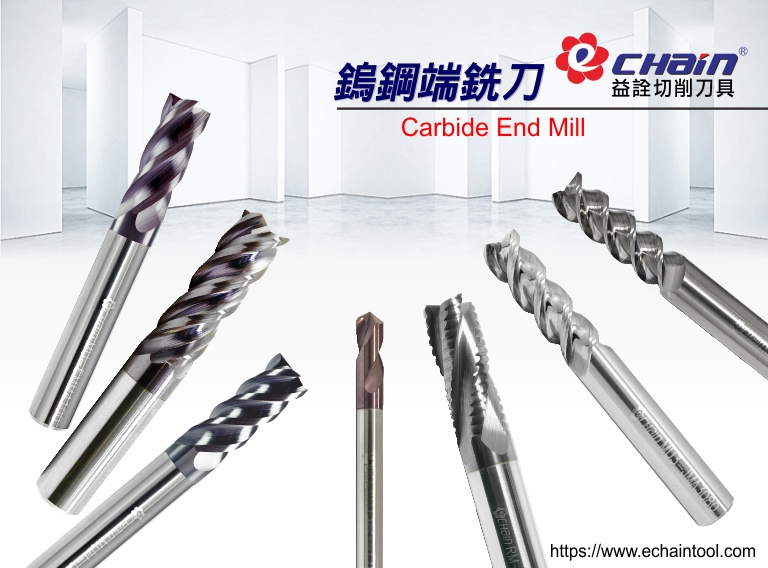

ECHAINTOOL PRECISION CO., LTD.

製品の説明 :

"Recently, in response to market demand, we have developed a number of new carbide end mills, starting with the "" Unequal split and Unequal spiral Carbide end mills"" (MUH-IMM Series) and "" Unequal split of Carbide end mills "" ( MUH-GMM series).

The two carbide end mills can enhance the vibration generated by the processing and increase the smoothness of the machined surface through the division ratio of the cutting edge. The unequal spiral design of the MUH-IMM series can strengthen the tool during high-speed machining. Anti-cracking; both carbide end mills have a special round groove design, which can effectively control the chip removal frequency during the plunge milling process.

In order to meet the market's processing requirements for aluminum alloys, copper and other materials, we also published the ""three-flute round land three-relief aluminum carbide end mills"" (MU3-JMA series): the cutting edge of the carbide end mills adopts three clearances. Grinding, improve cutting performance, have a better processing surface, round groove full polishing treatment, effectively suppress the heat generated during processing, make the chip breaking stable, smooth chip removal, and extend the processing life.

Regardless of the products such as turning tools, milling cutters, carbide end mills or accessory sleeves, ECHAINTOOL team has continuously developed and innovated, developed various specifications, and the first-hand new product release information is visible to the official fan group (HTTPS). ://www.facebook.com/

Phone: +886-04-2271-0856

"

TAILIFT CO., LTD.

製品の説明 :

全新推出ES-27全電伺服轉塔式沖床,採用全電系列AC伺服數控系統,具有高速、節能、高精度與低噪音的特色,加上過負載自動保護設計,是沖壓高精密薄鈑件的利器。它的集成式組裝方式,有效減少地面安裝空間。因具有沖孔、成型、滾切與攻牙等多功性能,可減少無效率工時的等待,大大提升加工效率。

另外節能方面,平均耗電顯著降低,無液壓油的消耗,是環性保護需求的綠色產品,這也是機身基座採O型龍門式架構設計,經世界級頂尖實驗室使用結構有限元素分析後,完成機身機座各部結構之靜性結構分析、剛性結構分析、暫態分析等應力結構性資料。

在構造機身基座之材料上,選用高強度鋼材焊接,引進尖端熱處理技術,消除焊接產生的熱內應力,使機身金屬結構完成統一機身機座,在精加工前更再經過高張力測試、正常化處理與震

動應力消除等三道防線嚴格把關,使機身組裝精度維持一致性。