展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

HOMGE MACHINERY IND. CO., LTD.

製品の説明 :

1) Patented stud bolt seat design can efficiently calibrate the clamping center.

2) It is recommended to operate with a Master Plate on a five-axis machine.

3) Compatible with Robotic Arms.

Product Data:

1.Vise body is made of High quality Steel (S50C) and its slideways gone through high-frequency hardening to achieve HRC50, which makes the whole part durable.

2.Detachable jaws are made of High quality Tool Steel (SCM440) and gone through carburizing to achieve HRC55. Since both sides are fixed size and able to be used as a datum, users can reverse them to increase clamping range.

3.The vise's clamping force can achieve 1300KG, the repeatability positioning precision of its clamping center is within ±0.02mm.

4.Users can calibrate the clamping center of vise by adjusting the screws on both ends.

5.The 45° dovetail structure with teeth on the upper jaw ensures the bottom of the workpiece to be firmly clamped.

6.Applications: precision machining of four-axis, five-axis, CNC indexing table and vertical and horizontal CNC milling machines.

VICTOR TAICHUNG MACHINERY WORKS CO., LTD.

製品の説明 :

.One piece 30˚ slant bed with large swing diameter

.10" Power chuck / 3500 rpm (A260)

. Z-axis travel 750 mm

.High thrust force by small pitch ballscrew

.High rapid feed 24 m/min (Z-axis)

.Shortened belt driven spindle

.Digital tailstock

.8” chuck for subspindle (opt.)

LEADWELL CNC MACHINES MFG., CORP.

製品の説明 :

Twin spindle & twin turret design, it can turn the different parts on the spindle and identical parts on both spindles at the same time. Integrated with 3-axis robot arms, to reach different OP and automation requested. Considering the turning efficiency, with automation high-speed robot reduces the loading/unloading time, with a high rigidity stricture design to increase the stability. On the other hand, the multiple types of robot arms will be able to satisfy the different demands of the client.

Max. swing: 290mm

Max. turning diameter: 290mm

Max. turning length: 220mm

X-axis travel: 195+5mm

Z-axis travel: 300mm

Spindle speed: 3500rpm

Spindle nose: A2-6

Chuck size: 10"

Spindle motor power: 11/15kw

Number of tool stations: 12T

ICOP Technology Inc.

製品の説明 :

DMP Embedded Mini PC series helps companies improve product quality and reliability, lower manufacturing costs with affordable price. EBOX Mini PC Series in 100 x 100mm and 75 x 75mm VESA Standard and DIN Rail designed, perfect platform for IoT, M2M, Industry 4.0, Home Automation, Security, Public transportation, Medical, Industrial controls, Point-of-Sales, kiosk, Thin Client, telecommunication, mobile surveillance, environmental monitoring, intelligent transportation systems, automated parking control systems and many other more.

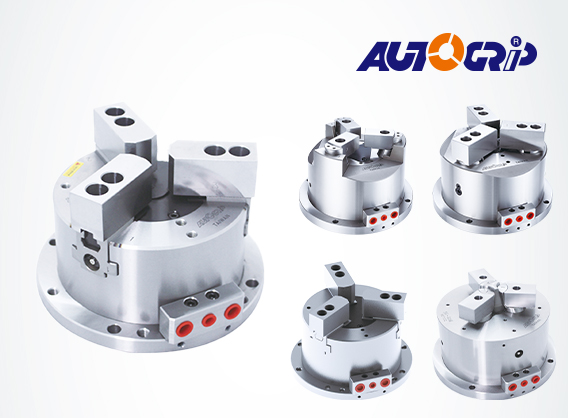

AUTOGRIP MACHINERY CO., LTD.

製品の説明 :

For stationary chuck, there are pull back, pull lock, thru-hole/non-thru-hole stationary chucks in the category.Multi-plate.4-plate(MP4)=>

For milling machine / machine center.

Allow simultaneous machining with up to 4 grippers.

(Order can be customized for 2,3,6 grippers).

Work with SP/SD/SU/SE vertical chuck.

Driven by Hydraulic or Pneumatic.

Individual circuit for each chuck.

Special design and reduce the height of working surface.

Lock valve unit (option).

Air tight detection function(option).

DYNA COMPRESSOR CO., LTD.

製品の説明 :

PM MOTOR

With powerful driving core, it is more energy-saving and energy-saving

The biggest advantage of permanent magnet variable frequency air compressor is energy saving by 10%~35% in average. It depends on the working condition of the air compressor and the setting of the frequency converter.

If the air consumption fluctuates, the energy-saving effect is better. Using a high-efficiency and energy-saving control system, the starting current is small and reduce the impact on the motor and electrical components; the life of the motor is extended, and the impact on the equipment and machinery is relatively reduced.