展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

Taiwan Laser Application Development Association (TLADA)

製品の説明 :

Established by law, non-profit social organization, that with the government to promote production

Industrial upgrading, and promote industrial upgrading professional laser application technology of energy produced by the Council and,

Government, and academia to exchange, establishment of industrial development consensus and dialogue with the government of the pipeline. "

Simultaneously through various international exchanges, and actively explore business opportunities, boost the global competitiveness of Chinese enterprises, the development phase for the case with the world。

JARNG YEONG ENTERPRISE CO., LTD.

製品の説明 :

This model can work with two axes gantry loader to transform CNC lathe be automation which is in order to accomplish automatic catching single blank material, uploading, unloading and clamping manufacture progress to increase physical labor productivity.

The most advantage is we can stand on the customer’s machining demand to choose the different types of feed stations.

SING CHIUN ENTERPRISE CO.,LTD.

製品の説明 :

Product categories include:

(1) UL WATERPROOF NYLON POWER

DISTRIBUTION HOSE

(2) STAINLESS WIRE BRADING CORRUGATED

NYLON TUBES

(3) NYLON TUBE QUICK CONNECTOR( Plastic steel )

(4) MS-PLUG/CONNECTORS ADAPTER( Plastic steel )

(5) NYLON TUBE COMPRESSION JOINT

(6) UL NYLON TUBE QUICK CONNECTORS ( Plastic

steel )

(7) UL MS-PLUG/CONNECTORS ADAPTER ( Plastic

steel )

(8) 2 1/2" NYLON TUBE CONNECTOR ( Plastic steel )

(9) NYLON TUBE QUICK CONNECTOR ( Simple type -

no waterproof )

TAIWAN 3AXLE TECHNOLOGY CO., LTD

製品の説明 :

Colour Marking Fiber Laser

Marking Machine

Good for metal materials, All polycarbonate material, plastic Stainless steel and other metal materials surface marking.

Laser safty goggles, Simple Fixture, External red light, Foot Switch.

Taiwan laser marking software

Availavle in 9 languages, English, Traditional/Simplified Chinese, German, Japanese, Polish, Portuguese, Turkish, Vietnamese, Portuguese, Turkish, Vietnamese.

Deep engraving, Metal marking, Serial number, QR code, Data matrix all in one machine.

Auto focus up to 4cm.

3D Rotary up 120º degree.

EANG LIAN CORPORATION

製品の説明 :

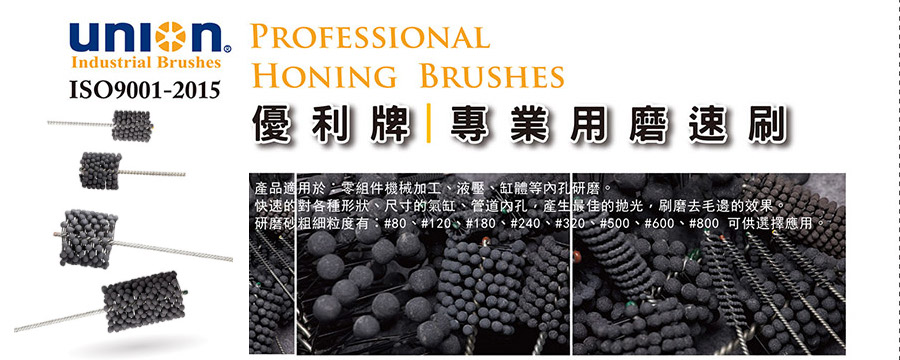

UNION Professional Honing Brushes Applications: Brake Cylinders, Hydraulics, Valve Guides Abrasive Type/Grit Size : #80、#120、#180、#240、#320、#500、#600、#800 Strong twisted wire handle for Hand or Drill use. Sizes to suit bores from 6.3 to 203mm. Ideal for surface finishing, blending and burr removal. Always use good quality honing fluid and start honing at low speed.</p>

PHB Flexible Honing BrushesF/lexible Honing Brushes