展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

SGCAM TECHNOLOGY CO., LTD.

製品の説明 :

國內市佔率最高的CNC車床CAD/CAM軟體<br />

全中文畫面,簡單易學、繪圖快速,最符合加工業使用的CAD/CAM軟體<br />

可由AutoCAD製圖畫出工件外形,再匯入DXF圖檔,轉換為CNC程式碼。<br />

3D動態實體切削模擬,可預先檢視切削路徑避免刀具干涉及過切。<br />

可設定架刀的安全角度,減少刀刃整面接觸工件而抖動,使刀具壽命延長。<br />

自動檢查、過濾、斷線、刪除重疊線段。<br />

準確的計算加工時間和工件重量,給予客戶精確的報價訊息,即時的爭取客戶的信任與訂單,決解你接單報價的困擾。<br />

支援完整切削複合循環功能G71、G72、G74、G75(不規則形狀也可使用G75) 。<br />

智慧型沿輪廓加工,節省加工時間(G73改良型) 。<br />

智慧型自動挑刀、斷屑、分層,直線、圓弧皆可自動做斷屑或暫停的動作,再也不用為斷刀而傷透腦筋了。<br />

人性化的刀庫設定,可依每位使用者設定不同的常用刀具。<br />

可做特殊造型螺紋切削、連續螺紋多牙嘴 。<br />

刀具路徑圖形化,刀具路徑也可直接作編修,編修完成G碼立即更改。<br />

弧長、角度、斜度比自動換算功能。

EQP SERIES CO., LTD

製品の説明 :

General-purpose, low-cost vibration sensor with an integrated sensor and amplifier, and an output current ranging from 4 to 20 mA. This low-cost and straightforward vibration monitoring sensor is ideal for controlling and monitoring rotating machinery. It offers three measurement modes: displacement measurement, velocity measurement, and acceleration measurement.

Due to the 4-20 mA DC output, it can be directly connected to recorders, displays, timing circuits, and other equipment. The integrated design of the sensor and amplifier eliminates the need for a separate vibration meter amplifier. It operates on a 2-wire system, comprising power and signal lines, with no polarity considerations during connection.

By connecting to a dedicated monitor or instrument relay, it can be used as a vibration meter or vibration measuring instrument. It is also compatible with Fuji Electric's MVM series.

※Can be used in conjunction with the Model-2590C display.

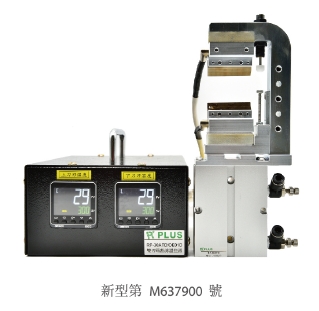

R PLUS TECHNOLOGY CO., LTD

製品の説明 :

Rplus pneumatic thermal cutters are designed for plastic molding and specified configuration. A designed pair of thermal knifes with a suitable heating rate, the unique design will reduce the heating time and reach the setting temperature in few seconds. The shearing is driven by a dual rod cylinder with 0.15~1Mpa range pressure.

Knifes are made by alloy special steel with heat-treatment. The heating capacity is 150W within 8mmx35mm heating bars , the range is 60~350C. The dual rod cylinder drives the thermal knifes will lead to a stable shearing effect, as well as higher efficiency, reduce the loss, faster shearing and depends on different type of plastic can be set variable heating temperature.

For modern manufacturing, we can integrate on a robot arm and automatically processing line.

Examples of widely application as head lamp of automobile,optical lens, acrylic products and Polycarbonate,etc. We forward to offer a safer , easier and efficiency tools.

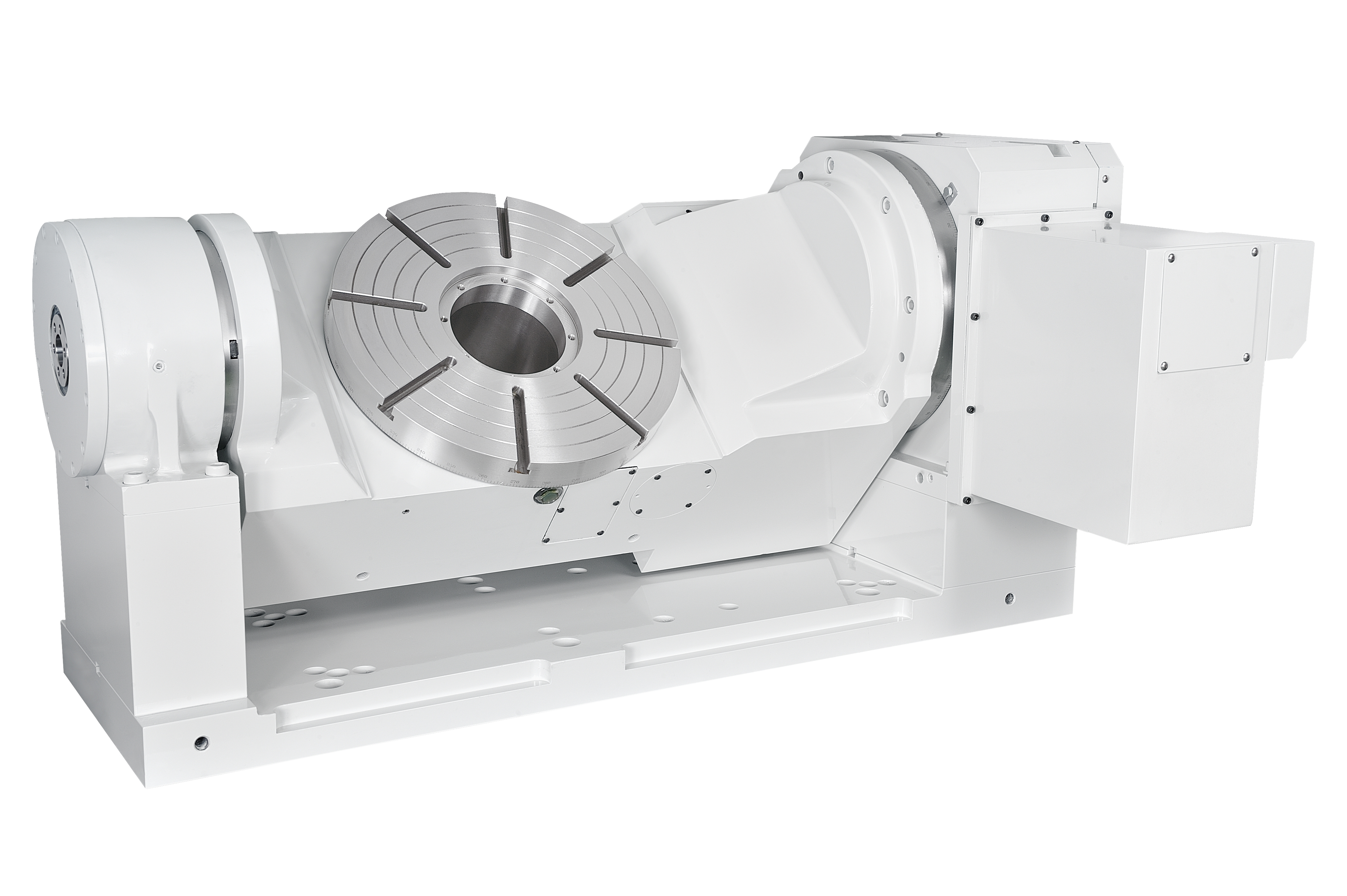

JARNG YEONG ENTERPRISE CO., LTD.

製品の説明 :

This model can work with two axes gantry loader to transform CNC lathe be automation which is in order to accomplish automatic catching single blank material, uploading, unloading and clamping manufacture progress to increase physical labor productivity.

The most advantage is we can stand on the customer’s machining demand to choose the different types of feed stations.

INNOSERV FA INC. TAIWAN BRANCH (BVI)

製品の説明 :

Micro Dynamics Vertical Machining Center Line opens a new era in multi-purpose and versatile machining centers. Compact, durable, powerful, strong and accurate, the MEGA/TERA Series starts a revolution in the market: the smallest C-frame machines provide powerful and precise results for manufacturers of dies and molds, aerospace, automotive, semi-conductor, job shops and general machine sectors.

The MEGA/TERA Series has been designed with the latest in technology being utilized throughout the machine with productivity in mind. From its EtherNet/IP architecture for easy automation and integration into systems and cells, to its Motion Control for fast and smooth operations used in all industries, the MEGA/TERA Series has quickly become one of the industries leading machine tool lines of Vertical Machining Centers.

The MEGA/TERA Series has been refined through years of research and development of new technologies that greatly enhance the machines for the rigors of the Mold and Die industry.

All series are equipped with

■ 15,000 rpm Built-In Spindle

■ Thermal Compensation (DYPEC)

■ Micro Dynamics HMI