展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

XMAC Global Co., Ltd.

製品の説明 :

德國雷神牌完整的產品線,從高階的全自動刀具補正系統(Tschorn 4.0)、3D探測頭,到普遍使用的偏擺式尋邊器、光電式尋邊器,以及Z軸定位器等產品,打造一站購足的服務。艾克斯馬克公司自德國原廠引進全套3次元維修設備、技術及零件,以提供客戶低廉的維修服務。指定公司貨,維修保固免煩惱,本系列產品已成為業界熱銷產品。<br />

<br />

德國雷神牌總裁Mr. Ralf Tshorn,為表示對台灣客戶的重視將抵台,主持發表會,並對支持的客戶致上誠摯的謝意。<br />

<br />

展覽期間,將舉辦探頭舊換新折扣、長針買就送等活動,詳洽艾克斯馬克公司(03-3779855)。 <br />

HWE DER MACHINERY AND HARDWARE PTY LTD.

製品の説明 :

Aluminum Alloys、Copper Alloy、For processing Copper and Aluminum Alloys

HUI BAO ENTERPRISE CO.,LTD

製品の説明 :

1. Different length nozzles for different purpose.

2. Aluminum body light weight and durable.

3. Maximum flow for easy clean-up and blow off even the heaviest shavings and chips.

4. Meets or exceeds OSHA regulations.

PRAISE PRECISION IND. CO., LTD.

製品の説明 :

Characteristics

1.Body is made of "S45C" with heat treatment.

2.Body and Center is under precise grinding process.

3.Application to lathe and grinder.

4.Morse Taper complies with DIN806 standard.

Taiwan Auto-Design Co.

製品の説明 :

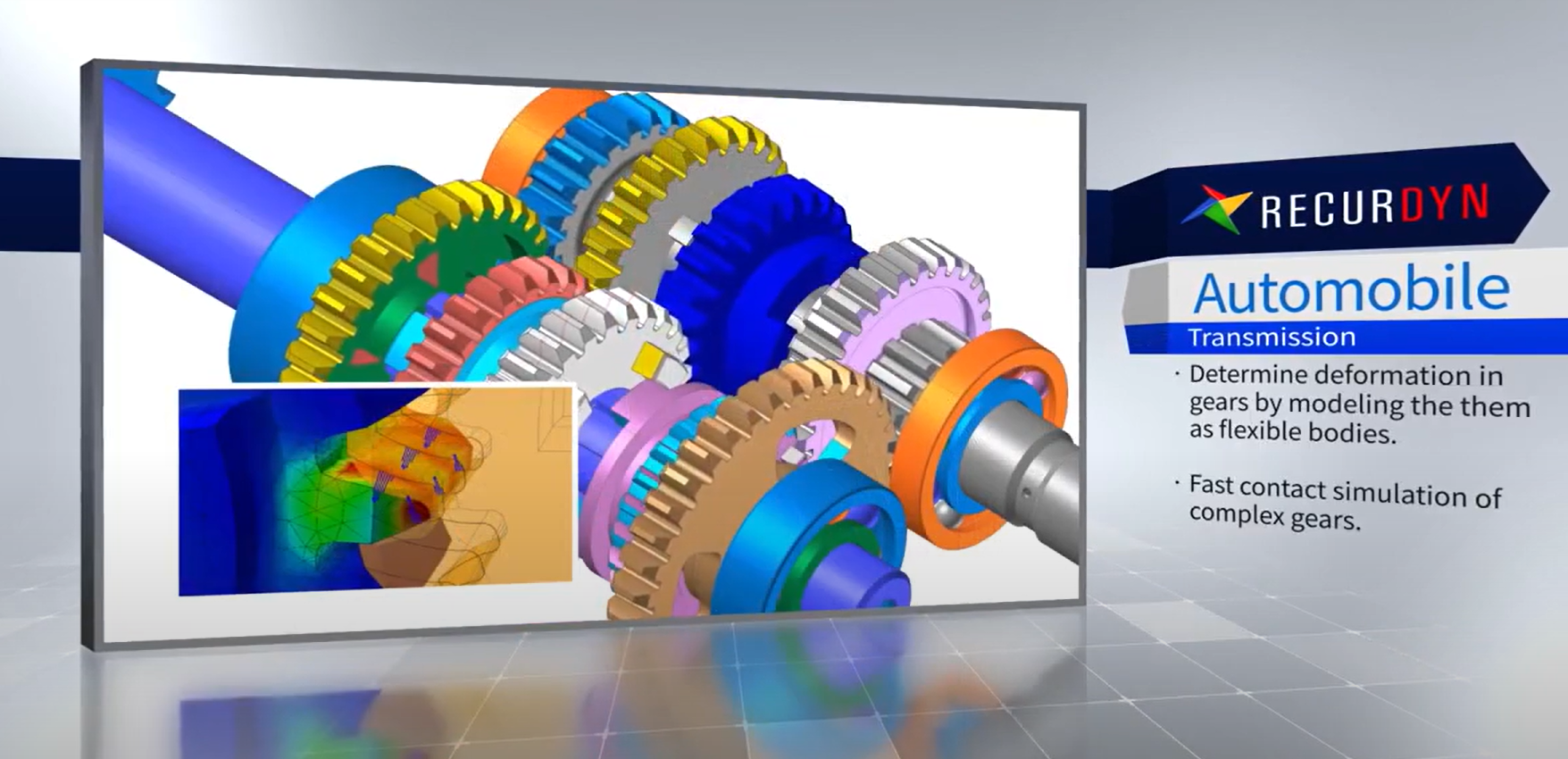

RecurDyn is an interdisciplinary CAE (Computer-Aided Engineering) software based on Multi-Body Dynamics (MBD).

It provides fast and efficient solvers, an intuitive interface, and various libraries.

RecurDyn simulates both rigid and flexible body dynamics by combining traditional rigid MBD with cutting-edge

finite element technology for modeling flexible bodies. In addition to MFBD (Multi Flexible Body Dynamics), RecurDyn

also includes a tightly integrated controller design tool, design optimization, and durability and fatigue analysis.

RecurDyn also supports co-simulation with various other CAE software tools. It enables a seamless co-simulation

environment (Particleworks Interface) for coupled simulations with computational fluid dynamics solver, Particleworks,

allowing for detailed analysis of the interaction of fluids and multi-body systems.

FUTECH PRECISION CO.,LTD.

製品の説明 :

Wedged 3-jaws type of hook with large through hole.

Hardened, ground and directly lubricated matching surfaces of all parts.

Construction of high rigidity, and high accuracy of clamping.

TAIWAN 3AXLE TECHNOLOGY CO., LTD

製品の説明 :

Created to meet the demands of modern welding, MAXWELD combines a stylish appearance with outstanding performance. Focused on space optimization, it makes your workspace more spacious and efficient. MAXWELD is the world's first model to adopt a large-area airflow design, specifically designed for high-temperature environments within factory facilities. This unique airflow design ensures that the equipment maintains effective cooling even under high-temperature conditions. Additionally, MAXWELD comes equipped with dust-proof cotton to effectively prevent dust from entering, ensuring the stable operation and extended lifespan of the equipment.

MARPOSS CO., LTD.

製品の説明 :

BLÚ是馬波斯在磨床及其他機床的過程優化管理應用中五<br />

十多年經驗的结晶。<br />

BLÚ是一个模擬化系统,由一系列功能節點组成。通過由<br />

主控節點控制的單一總線,所有節點互相聯接,從而形成<br />

一个獨立網络。系统主控節點通常放置在机床電控櫃裡。

CHIEN CHENS MACHINERY CO., LTD.

製品の説明 :

Specification

Table size: 1515 x 470 mm

Longitudinal travel: 1300 mm

Cross travel: 600 mm

A axis travel: 370 mm

Y slide way width: 720 mm

Z Slide high: MAX 700 mm

Z Slide way width: 420 mm

Spindle taper: NT#40(BT)

Spindle motor: 5HP / 4P

Spindle speed: 70~3600 RPM

Horizontal Spindle motor: 5HP / 4P

HorizontalSpindle speed: 70~3600 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø32 mm C5

Net weight: 3500 kgs

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

XYZ axes travel: 500x400x185mm (20"x16"x7") inch

U axis travel: 300mm (12") inch

Z axis single travel: 400 mm (16") inch

Work table: 800x450 mm (31"x18") inch

Max. Workpiece: 1250x650x390 mm (49"x26"x15") inch

Max. Workpiece weight: 1400 kg

Max. Electrode weight: 185 kg

Machine net weight: 2100 kg

Oil level: 110-360 mm (4"-14") inch

Packing Size(LxWxH):2340x2320x2500 mm (92"x91"x98") inch

Work Table to platen:

1. Z axis single travel: 230-630 mm (9"x25") inch

2. UZ axis: 230-715 mm (9"x28") inch

Filter: 1

Paper filter:2

Capacity:550 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.