展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

BENIGN ENTERPRISE CO., LTD.

製品の説明 :

• Heavy duty mill for wide range of applications

• Machine body is made of Meehanite casting.

• 5 HP inverter driven spindle, variable speeds

• X & Y axes automatic feeds driven by 1⁄2HP 12P motor and inverter

• Z axis rapid up-down driven by 1⁄2HP 6P motor.

• ISO 40 spindle, quill diameter 105mm

• Y & Z axes square ways

• Turcite-B coated on X & Y saddle.

• Hardened table and all slide ways.

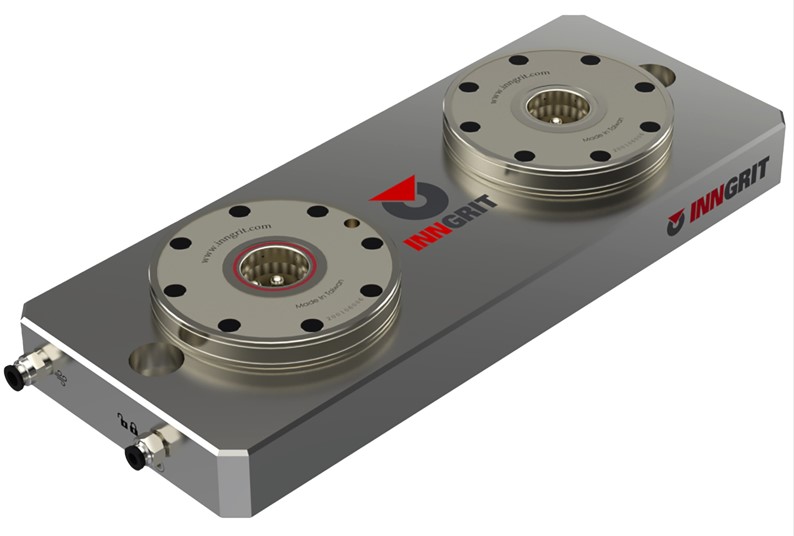

Inngrit Co., Ltd.

製品の説明 :

• 特殊專利具有吹氣清潔/氣流迴路,可提高操作效率,進而提高生產力和安全性。

• 實現驚人的<0.005 mm重複精度

• 夾持力為2,000KG(油壓)和1,000KG(氣壓)

• 上浮功能,取放方便,維護方便

• 英貴爾原點定位系統配合機械手臂和控制系統,可利用自動夾取、吹氣、檢知功能,透過程式控制實現快速、準確的工件夾緊和取放,實現自動化智慧生產

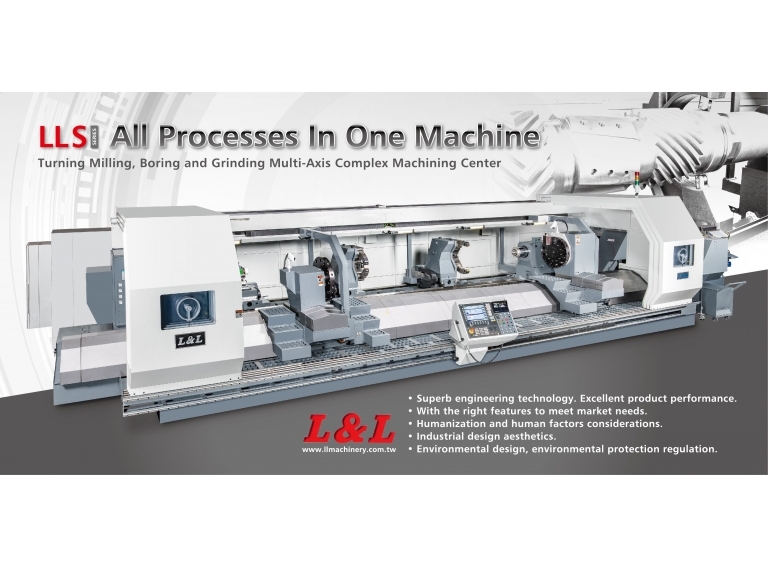

L & L MACHINERY INDUSTRY CO., LTD.

製品の説明 :

L&L LLS multi-axis composite cutting center machine, targeting the plastic rubber machinery industry, the application function exceeds customer demand:

a. Reduce the number of times of machining twice, reduce tool interference, and reduce work time by 50%.

b. Bed structure patent, one-piece casting, μ-level scraping process to ensure accuracy and stability.

c. Programmable tailstock, hydraulic center frame, independent chip removal device, programmable automatic door, high speed splash screen, full cover sheet metal design.

d. Full-cover design reduces the leakage of coolant, the design of the coolant collect plate for bed base, and the addition design of oil mist collector to reduce oil and gas pollution.

SESAME MOTOR CORP.

製品の説明 :

Sesame Motor has engaged in offering excellent quality planetary gearboxes, gearheads and gear reducers to our valuable clients for almost 30 years. Multiple designs, models, performance levels and customized motor brackets to offer different ranges of power transmission solutions. Precision gear design and processing incorporate one-piece planet gear carrier and output shaft to provide higher radial load, increased service life and low backlash.

Visit https://www.sesamemotor.com/products/en/

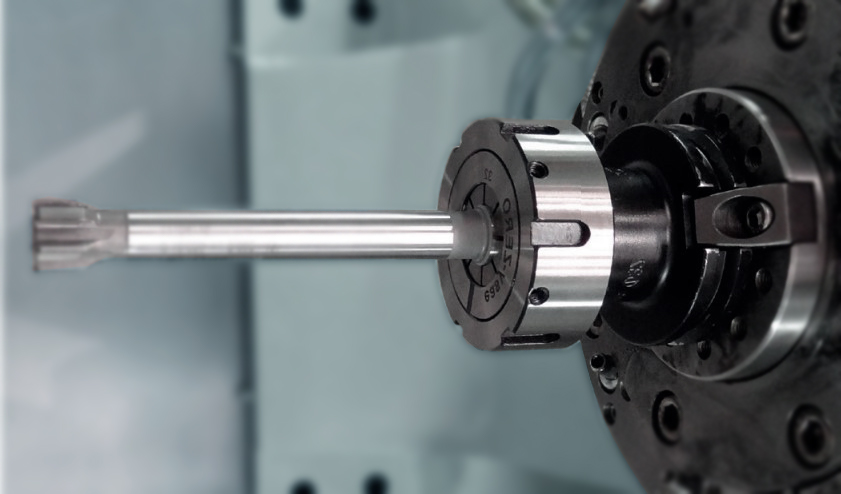

MONGTEC PRECISION INC.

製品の説明 :

Product Features

◎ Correction of runout errors and misalignment

◎ For metallic sealed and normal collets as per DIN 6499 / ISO 15488

Product Advantages

◎ Easy to set

◎ Maximum process capability due to correction of runout

◎ Extended tool life due to perfect runout

◎ Highest quality of bores due to correction of runout

FALCON MACHINE TOOLS CO., LTD.

製品の説明 :

Improved grinding performance, precision and stability

Chevalier's FSG-20/24ADIV Series of surface grinders now includes four new machine sizes, along with several newly designed features: a traveling column structure to further reduce vibration and achieve higher accuracy; a spindle that can withstand heavy load grinding; and a double-V guideway for smooth, stable longitudinal movements. Fully supported worktable design. Maximum table speed: 30 m/min (98.4 fpm), increases processing efficiency. Integrated machine-body temperature control system greatly improves accuracy and stability.

These four larger sizes, along with the entire FSG-20/24ADIV Series, offer several design features to shorten processing and non-processing preparation while delivering high-precision workpieces: iSurface control, variable speed spindle, constant surface speed, smart grinding path and in-machine manual dynamic balancing.

The driving forces behind this series pave the way to smart manufacturing by meeting the current grinding demands and standards required by the automotive, electric vehicle, mining, aerospace and job shop industries.

CHIEN CHENS MACHINERY CO., LTD.

製品の説明 :

Specification

Table size: 2600 x 650 mm

Longitudinal travel: 2400 mm

Cross travel: 800 mm

Y slide way width: 1980 mm

Z Slide high: MAX 800 mm

Z Slide way width: 500 mm

Spindle taper: NT#50(BT)

Spindle motor: 7.5HP / 4P

Spindle speed: 70~1200 RPM

Feeding speed: 10~6000 mm/min

Ballscrew: Ø40 mm P=8 C3

Net weight: 6800 kgs

KING NICE TECH.CO., LTD.

製品の説明 :

It can effectively separate the slide oil,foreign matter oil,etc.on the surface of the water tank.Reduce the foul smell produced by the fusion of cutting fluid.

Reduce oil mist and liquid fly rafts causing grease on machinery and workpieces.Free from skin irritation and allergies.

No need to discharge,can reduce the amount of waste oil and wastewater treatment.

Reduce workpiece corrosion,rust,improve machining accuracy and extend tool life.

Purify cutting fluid to stabilize its quality,extend life and improve processing efficiency.

Filter impurities such as suspended solids to prevent backlash form affecting the surface of the motor and theworkpiece.

Stop theproduction of anaerobice bacteria and reduce the frequency of changing cutting fluid.

Reduce the failure rate of pipe and motor blockage.

Reduce labor costs and cleaning time for cutting fluids .Save processing costs for waste oil recovery.