展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

JEFFER MACHINERY CO., LTD.

製品の説明 :

ASG-800 is an Automatic Carbide Saw Grinder. Original design idea and goal is by the user-friendly, clear operation panel, the PLC numerical control and stores up huge tooth patterns inside it. The machine could grind different kinds of TCT saw blades and can store up common tooth patterns up to 100 groups. It has automatic compensation program to set up grinding wheel compensation. It also can adjust grinding speed and has automatic lubrication system. This is a multi-purpose Automatic Carbide Saw Grinder.

ASG-800 Feature :

1. Using Servo dividing on grinding wheel angle is fast

with high accuracy.

2. It can adjust high and low speed on grinding wheel up

and down movement, which can save working time.

3. Servo used on fixing position for pushing tooth with

precise and fast orientation.

4. With automatically right-left moving on grinding wheel

while working, this can reduce grinding noise and can

sharpen knives well.

5. Grinding capacity : dia.120~800

Saw blade bore diameter: dia. 10~85

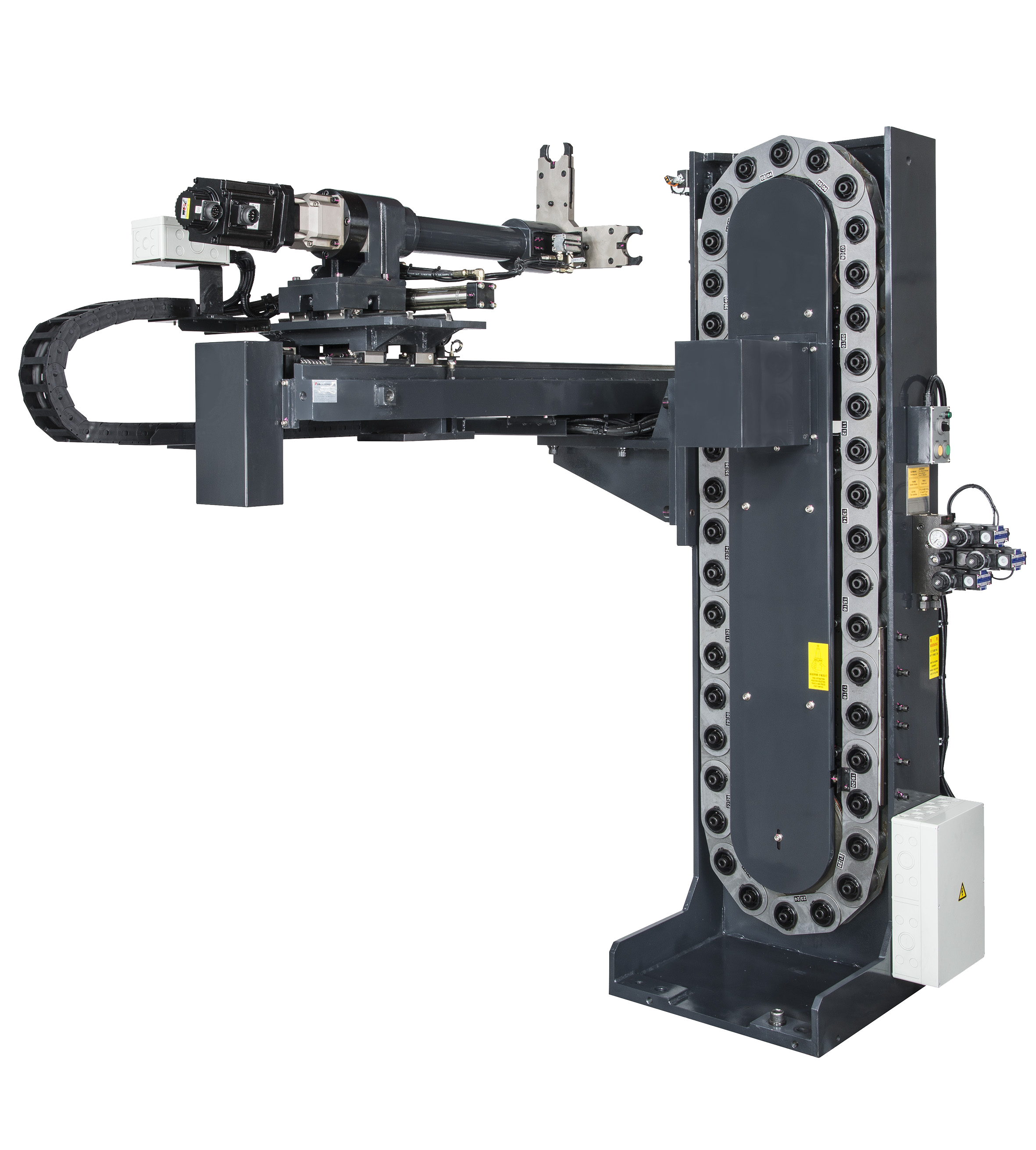

GIFU ENTERPRISE CO., LTD.

製品の説明 :

Applicable Specification:

BT40/CAT40/DIN40/HSK63/CAPTO6

Applicable Model:

Multi-Tasking Machines

1.L-shape arm allows speedy tool changing with short sequence. Besides, low swing loading makes long product service life.

2.The main chain wheel is driven by servo motor, which achieves accurate positioning, fast tool selection and multi-tasking tool management.

3.The long-distance movement is driven by servo motor, which achieves fast and accurate positioning.

4.Expandable tool storage.

BEST DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

Compared to resin bond and metal bond wheels, Electroplated Grinding Tools are noted for relatively large grit protrusion and higher abrasive concentration. This results in very free cutting properties and in high stock removal capacity. Besides, these tools are noted for:

1. Allow special shapes and profile tools to be made at short notice.

2. Cause very little change on wheel shape after used, suitable for precision grinding.

Application and Processing Material for Electroplated Grinding Tools :

1. Internal grinding: Suitable for the internal grinding of carbide and High Speed Steel. The smallest diameter of our electroplating area is 0.3mm so it could be used in drilling for fined ceramics.

2. Jig grinding: Mostly used in fined ceramics processing and precision grinding for quartz. Customized items are also provided to cater your needs. Common grit size is #80~#325, good for rough and fine processing.

3. Touchscreen Processing: Drilling and chamfering for the glass panel of the smart phone and tablet computer. In order to improve work efficiency, we could also combine different grit sizes in the same diamond mounted point.

4. Grinding for Cutting tools: Normal end-mill grinder and drill grinder go with electroplated wheel. Carbide can be ground by diamond wheel and High Speed Steel could be ground by CBN wheel. Bowl-shape wheel with standard specification is also provided, suitable for the grinding of turning tools.

5. Precision grinding: Electroplating can produce wheel of different shapes without deforming it. Therefore, it is suitable for precision grinding or trimming aluminum oxide wheel.

6. Gem grinding: shape grinding for gem, semi-precious stones, shell and jade.

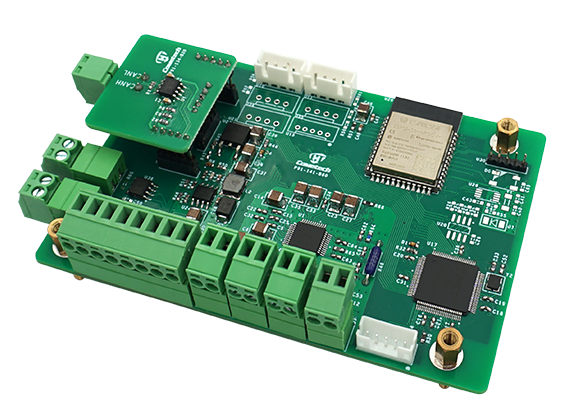

COMETECH TESTING MACHINES CO., LTD.

製品の説明 :

※Specification

-Power Supply: DC 24V

-Sensor Input: Two-wire Empire T.C. (4 sets)

-Control Output: SSR (4 sets)

-Communication Interface: Built-in Wi-Fi module and RS-485; RS-232, CAN Bus for options

-Accuracy:± 0.25% F.S. or ± 1.0℃

-Control Method:4-PID Control

-I/O(photocoupler):4 Inputs, 4 Outputs (Open Collector)

-Heater Element Burnout Detect:4 Sets for options

-Display: 2.8" wireless color touch screen for options

-Software: Equipped with dedicated temperature monitoring software which is available to connect with mobile devices (smartphone, pad, notebook, etc.) through Wi-Fi.

※Features

-Compact structure to save installation spaces

-Up to 4 heating and 4 temperature detection channels

-Data setting and devices' status monitoring by dedicated software through Wi-Fi connection

-Over-the-air firmware update

-Heater element burnout detection for easier maintenance

-Modbus-compatible driver for various host controller

-Multiple I/O (open collector) for flexible expansion of different applications

Cartell Chemical Co., Ltd.

製品の説明 :

我們的厭氧膠分為四大類:

◆螺絲固定劑:能完全填充螺紋之間的空隙,可以取代彈簧墊圈、雙螺母,及其他機械固定裝置,簡化產品的設計,並可防止螺絲扣件腐蝕、卡死、鬆動、滲漏、減少維修時間,永久確保螺絲裝配的安全,提高機械的穩固性。

◆圓形配件固定劑:主要應用於各種金屬圓柱型零組件的組裝。如:軸承、軸套、插銷、鍵槽、齒條、輪轂及滑輪等圓形配件的組裝固定,取代傳統的壓配、插銷、鍵槽等費時費力高成本的工作方式,改為簡易的輕壓配或滑配的方式。

◆管路密封劑:適用於金屬螺紋配管。它可以固定、密封金屬管路系統,填充金屬零件與螺紋之間的空隙,並防止洩漏、承受管路壓力、防止熱脹冷縮或震動引起的鬆脫和洩漏。

◆法蘭墊片密封劑:適用於各種尺寸的平面表面。它取代了傳統墊片,從而降低庫存成本。其特點包括無溶劑成分、高黏度、耐壓性和使用便捷性。相較於預先切割的墊片,其優勢在於簡化工藝、降低缺陷率、減少生產混亂,以及與多種黏著方法相容。

HEIDENHAIN CO., LTD. (TAIWAN)

製品の説明 :

In addition to milling operations, the TNC 640 also combines operations from milling, turning, and grinding processes. This sets the TNC 640 apart as a high-end control within its field of application. It is particularly well suited to HSC and 5-axis simultaneous machining, including on fully automated machining centers. The TNC 640 stands for perfect surface quality, exceptional accuracy, and very short machining times combined with shop-friendly operation and programming. On a milling/ turning machine with TNC 640, you machine the complete work piece on one machine in whatever sequence is needed. You can switch back and forth regardless of the machine and its axis configuration. The TNC 640 makes all necessary adjustments, e.g. switching to diameter display and setting the datum in the rotary table center. Batch Process Manager allows you to optimally plan and execute production jobs with great ease. With Batch Process Manager you can flexibly define the sequence of your jobs and, prior to machining, check to ensure that all of the required tools are available and that the NC program will run without errors.

A Being Kou Tools Co., Ltd.

製品の説明 :

After becoming frustrated by the existing coolant hose products on the market; all of which suffered from a variety of shortcomings, Arnold Lockwood conceived the idea for the modular hose that became Loc-Line®. The shortcomings of the existing products included, metal coolant hoses that would not stay where they were positioned and plastic hoses with metal positioning rods that broke.

In 1981 Lockwood Products was formed to develop and distribute Loc-Line®. The first products were shipped in August of 1983.

Loc-Line® quickly became the standard for coolant delivery around the world and was easily recognized by our Blue and Orange colors and consistent high quality.

Today Loc-Line® is still the leader in modular hose and continues to innovate in the modular hose field. Loc-Line® is used not only as a coolant hose but for air delivery, smoke and dust removal vacuum systems, agriculture, third arm uses including positioning cameras, lights and items for handicap assist.

We here at Lockwood Products, Inc are proud to have originated the modular hose Loc-Line© that remains the standard for the industry worldwide!

Please visit one of our distributors today and see for yourself why Loc-Line remains the best and most versatile solution in the world today!

EUMACH CO., LTD.

製品の説明 :

GVM-800U 專為高精度複雜多曲面銑削而設計,只需一次裝夾,甚至可以車削。從靜態剛性和動態質量的角度來看,每個關鍵部件的堅固框架都經過了很好的優化,以成為最高性能的天車式五軸加工中心。 雙Y軸驅動龍門型結構,絕對抑制了極高速(48m / min)加速/減速產生的振動。不僅可以提高生產前置時間,加工精度,還可以通過緊湊的設計優化工作環境,提高公司的整體管理水平。

直接驅動工作台由二個扭矩電機驅動,A和C軸各一個,最大速度50/100RPM,最大負載920/1200kg,旋轉角度A/C軸±125゚/ 360゚,達到新的高水平動態銑削和車削操作!

刀庫是由交流伺服電機驅動,以簡單,快速,無故障和極其平滑的刀具交換,標準32把刀及更多選擇。高速內藏式銑/車削電主轴18000~24000RPM可供選擇。搭配HEIDENHAIN TNC640,15”螢幕的五軸連動控制器,HEIDENHAIN高精度三軸光學尺,該加工中心用於飛機渦輪元件的加工及鋁製汽車輪圈高速表面處理提高了生產力。

JIN TAIRY ELECTRIC CO., LTD.

製品の説明 :

JPS Technical Specifications

• Input voltage regulation range: rated voltage±15%

• Output efficiency: more than 95%

• Output stability rate: rated voltage±1%

• Waveform distortion: No distortion (compared with input waveform)

• Overload capacity: Above 150% of the rated output current

• Working environment: -0C~+40C

• Induction time: less than 0.1 seconds (less than 5 weeks)

• Working humidity: 95%

JPS Features

• Intelligent logic voltage regulation method

• Self-detection function

• LED indicator on the panel

• Patented bypass device included

• Large-range over-high and low-voltage protection device

• Under-phase instantaneous power failure short-circuit protection device

• Prevent activation of over-voltage device (SOVP)

Electronic double circuit panel design

• The internal panel voltage can monitor the three-phase voltage

• The DIP switch function is easy to set up

• Separated voltage stabilization design, three-phase unbalanced 100%

• Taiwan Patent No. 60215 62577

• Mainland Patent No. 12559 5390066