展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

DYNA COMPRESSOR CO., LTD.

製品の説明 :

2 STAGE ROTARY SCREW

Powerful two stage compression performance surpasses one stage compression.

For this series of new designs, we use two-stage compression. The compression efficiency creates the most energy-efficient air compressor, keeping the flow rate, power consumption and temperature in the best condition, making the screw air compressor more energy-saving, more power-saving, and more suitable for your use. Improve your production efficiency, and also greatly save power consumption. Our design and manufacturing technique has always been being the quality guarantee.

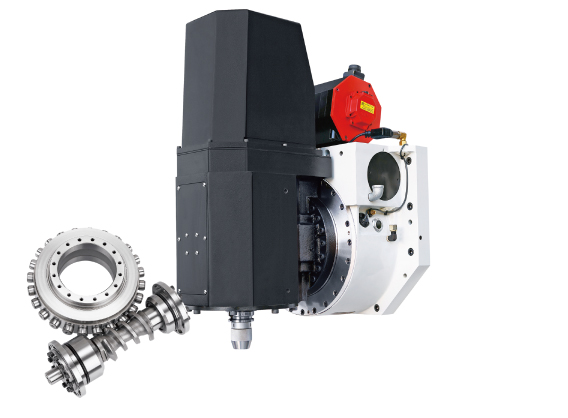

Hantop Intelligence Technology

製品の説明 :

Tool Holder Spec. provided:

BT30, BT40, HSKA63, HSKE25, HSKE32, HSKE40, CAT40

1. High Speed, high efficiency ultrasonic machining solution for high precision advanced materials machining(can reach 38000 rpm)

2. Plug and Play design for convenient and flexible Installation

3. Effective Intelligent Tracking System for advanced materials machining, finding the suitable resonance between tools and modules

4. Non-Contact transmission Design doesn't limit the high spindle rotation and reduce the impact from cutting heat, enhancing tool life and quality to next level.

VISION WIDE TECH CO., LTD.

製品の説明 :

GSF Series 5-axis Gantry Type Machining Center, provided excellent 5-axis simultaneous accuracy performance for 5-axis machining in mold cutting, highly precise contour finishing, milling, drilling, and tapping. Vision Wide manufactured the 5-axis machining center to shorten tool displacement travel and cutting process effectively, and to extend tool lifetime and offer the best choice for composite angle machining. GSF Series had excellent dynamic performance on one-piece structural and equipped high accuracy 2-axis head to achieve 5-axis simultaneous accuracy performance.

•Continuous 2-axis head

•5 axis dynamic rotation synchronization accuracy (TCPM) 0.04mm.

•Built-in Spindle Direct-Driven on B&C axis, 12,000~24,000rpm spindle speed.

•Backlashless driving on B/C axis,Rotation Positioning accuracy ±5”.

•Low table height, closer operating zone, wider door width are convenient design for user.

•Chain type chip conveyor (standard) is able to remove iron chips efficiently.

ACCUTEX TECHNOLOGIES CO., LTD.

製品の説明 :

Linear Shaft Motor

Rapid servo control, enhancement of sensitivity in discharge gap control. Improving cutting speed up to 8~10%

1/1000 High Resolution Signal Process

High resolution in linear scale, achieve more smooth velocity control, and enhance the stability of position control, best match up contouring accuracy.

Stable Discharge Board (SD-Master)

Irregular Thickness Cutting

The AccuteX intelligent discharge unit is capable of dealing with the changing conditions in workpiece thickness and water flushing situations, featuring high cutting speed, and free from wire breaking problems.

PCD Cutting & Graphite Machining Power supply

The collapse of workpiece edge by wire cut can be controlled within minimum range along with high speed machining.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

XYZ axes travel: 600x400x400mm (23.62"x15.74"x15.74")

W axis travel: 450mm (17.71")

Work table: 650x450mm(25.59"x17.71")

Max. Workpiece: 900x500x300mm(35.43"x19.68"x11.81")

Max. Workpiece weight: 700kg

Distance from table to guide plate:25~425mm(0.98"x16.73")

Machine dimensions: 1580x1250x2740(62.2"x49.21"x107.87")

Machine net weight: 1200kg

Electrode diameter: 0.2~3.0mm

Dielectric fluid: pure water ( dielectric oil for 0.2mm or below)

Filtration: Paper filter

Controlling axes XYZW

Monitor: 15” LCD screen

Input/output unit: LAN/USB

Min. Setting Unit: 0.001mm

Min. Moving Unit: 0.001mm

Graphical display: 2D

Machine Features

1. This system utilizes Windows CE controller.

2. Able to store data through USB and internet.

3. Dialogue window, along with picture description functions.

4. Touchscreen type interface.

5. Special repaired frames to quicken the maintenance speed.

6. Close-Loop design of digital feedback on three axis of the machine, significantly increases positioning accuracy.

7. Possessing good and simple operation interfaces

Common function keys are located on the operation panel for direct use, hot key function on screen for quick access.

8. ATC (automatic tool changer) and AGC(automatic guide chnger) can be installed

9. Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to search.

10. Automatic origin search and multi-point coordinate memory capability.

11. Chinese/English versions, Metric/British system switch and quick up, quick down, and slow up and slow down capabilities, resolution can reach 1um.

12. All alarms describe the source, data and exact time of problem occurrence.

13. Able to proceed standard GM code and extra GM code

14. Able to proceed DXF file transfer to position coordinate function

15. AB axis rotate table can be installed

16. Position simulation and work route can be displayed

17. During discharge change new electrode can automatically compensate depth

18. Backlash point automatic compensate function

19. Able to do single hole drilling, multiple hole drilling and multi thickness drilling

20. Blindhole drilling function, any depth can be set

21. Initial current can set to reduced value, which can prevent workjob surface damage

22. Initial polarity reverse function, can prevent uneven electrode caused efficiency decrease

23. Six axis linear interoperate accelerate speed movement

24. Input, output, various of machine status real time display system

25. Discharge program and parameter conversion function

Accessories

《 Standard Accessories for High-speed Drilling CNC EDM 》

Tool Box*1

Brass Electrode 1.0mm*10

Electrode Guide 1.0mm*1

Standard Chuck*1

Foot Pads*1 set

Filter*1

Rubber Seal*10

Halogen Work Lamp*1

Flushing Unit*1 set

《 Optional Accessories for High-speed Drilling CNC EDM 》

ATC

Electrode Guide(Other diameters)

Brass Electrode(Other diameters)

ER Type Chuck for electrodes up to 6mm

Submerged Work Tank

75Amp Power upgrade

Filtration System with Resin Bottle

A,B Axes

Automatic guide changer 3/6

OWNNER INDUSTRIAL CO., LTD.

製品の説明 :

Standard Gang-type or Turret(optional). Gang-type permits quick tool change. Gang-type tool system can make tools change faster. Increase the external oil tank and lengthen the oil temperature cooling time.The oil temperature natural cooling principle is adopted to make the processing oil temperature more stable.

JAR HON MACHINERY CO., LTD.

製品の説明 :

1.Both cutting TAP and forming TAP are suitable.

2.Fully automatic tapping process. One operator can easily operate several machines at the same time.

3.By using proper master pitch gears(change gears A and B pair), highly accurate thread can be tapped. It is easy and quick to change different size.

4.The length of the tapping stroke can easily be adjusted for high accuracy which is suitable for tapping blind hole parts.

5.It has safe device to monitor the feeding, torque, radial, and clamping to keep TAP's long life and ensure safe working job.

6.It governed by PLC.

7.Long parts or those can't feed in vertical position are suitable.

8.Pre-work parts auto-checking and machine auto-stop if abnormal.