展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

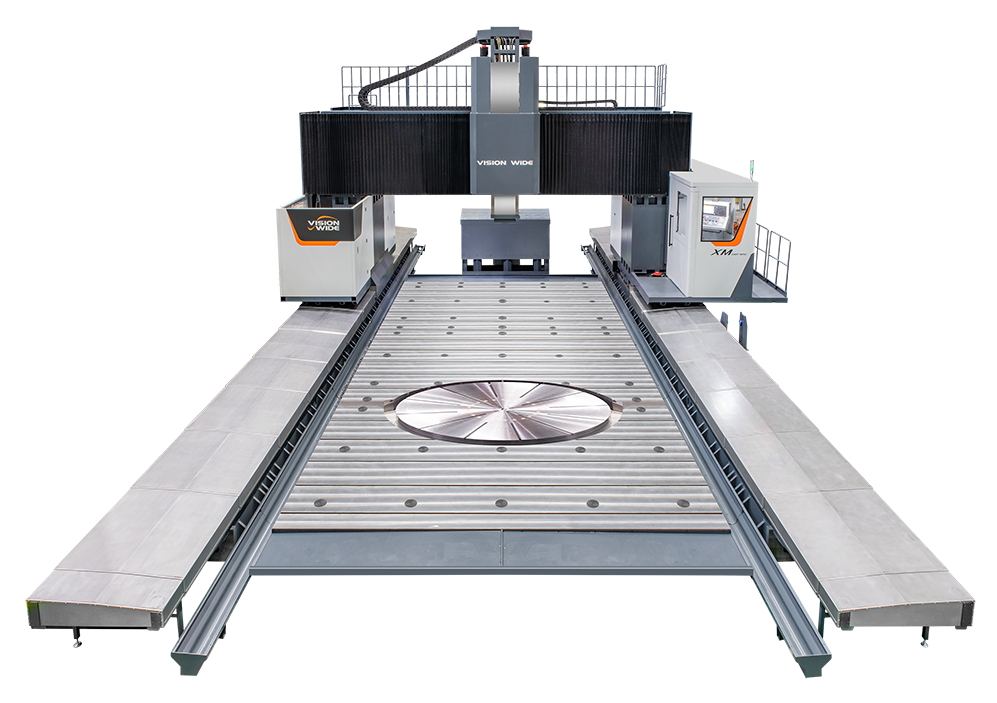

VISION WIDE TECH CO., LTD.

製品の説明 :

High Performance and Wide Application

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

• High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

• Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

• Fully automatic multi-face machining: This moving column machining center can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

• Milling and turning compound multitask: This moving column cnc milling machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.

SHENG FENG TECHNOLOGY CO.,LTD

製品の説明 :

Cross roller bearings consist of inner rings, outer rings, spacer retainers and cylindrical rollers cross arranged on the V-shaped 90° groove between the inner and outer rings. This structure can withstand radial, axial and moment loads in all directions because the rollers'line contact with raceway surfaces achieve a large load-bearing area despite the minimum dimensions. Therefore these bearings are widely used on the rotating parts of industrial robots, machine tools, precision rotary tables, measuring instruments and IC manufacturing machines.

Cross Roller Bearing Features:

High rigidity

Large load capacity

High rotation accuracy

Compactness

Easy to install and handle

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

X axis travel:

Single movement: 2550 mm (100") inch

Dual movement: 1275 mm (50") inch

YZ axes travel: 850x600 mm (33"x24") inch

※Y axis can be increased to 1300 mm(51") (Option)

※Z axis can be increased to 1000 mm(39") (Option)

Work table: 3100x1600 mm (122"x63") inch

Max. Workpiece: 4100x2050x1250 mm (161"x81"x49") inch

Max. Workpiece weight: 22000 kg

Max. electrode weight: 500 kg

Machine net weight: 29410 kg

Oil level: 110-1000mm (4"-39") inch

Occupy size(LxWxH): 6480x6600x4600 mm (255"x260"x181") inch

Work Table to platen:

600mm Z travel machine: 1138-1738mm (45"-68")

1000mm Z travel machine: 740-1740mm (29"-69")

Filter: 4

Paper filter:8

Capacity:11300 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

TAIWAN MACHINE TOOL CO., LTD.

製品の説明 :

TMT TG series with meticulous design, is your best choice in precision finishing. Multi-performance, while satisfy different machining demand. Work table can be mounted with APC, 5 Axes or fix table.

-High cutting rigidity with ganty type structure design.

-Compact design less floor occupation.

-Without carring ATC system on moving parts to make it lighter, make sure cutting without vibration.

- Cutting area isolation to ensure the transmission system life longer and easier to install linear scale.

-High efficiency servo drive ATC system, C-C(T1-T2)only 4sec., with high stable performance.

-ATC install at the center of basement to reduce the width of machine to save the walking steps to loading and unloading workpiece.

CHING HSYANG MACHINERY INDUSTRY CO., LTD

製品の説明 :

1. This machine is designed for internal and external shaving of round

tubes.

2. The center line of the processed object and the insert head is accurate.

3. The clamping die and the insert head are designed to be uniform, and

the work piece can be processed uniformly at one time.

4. The insert head is specially designed, the blade is standardized, and the

adjustment tool is simple and fast.

5. Feeding by manual, automatic advance and retreat blade, fast speed,

suitable for material steel pipe, iron pipe, aluminum pipe, copper pipe,

stainless steel pipe, plastic pipe, non-metal material and carbon fiber

pipe.

6. The machine is randomly matched with the multiple clamp, which can

be applied to different pipe diameters, saving time and cost for

replacing the clamp.

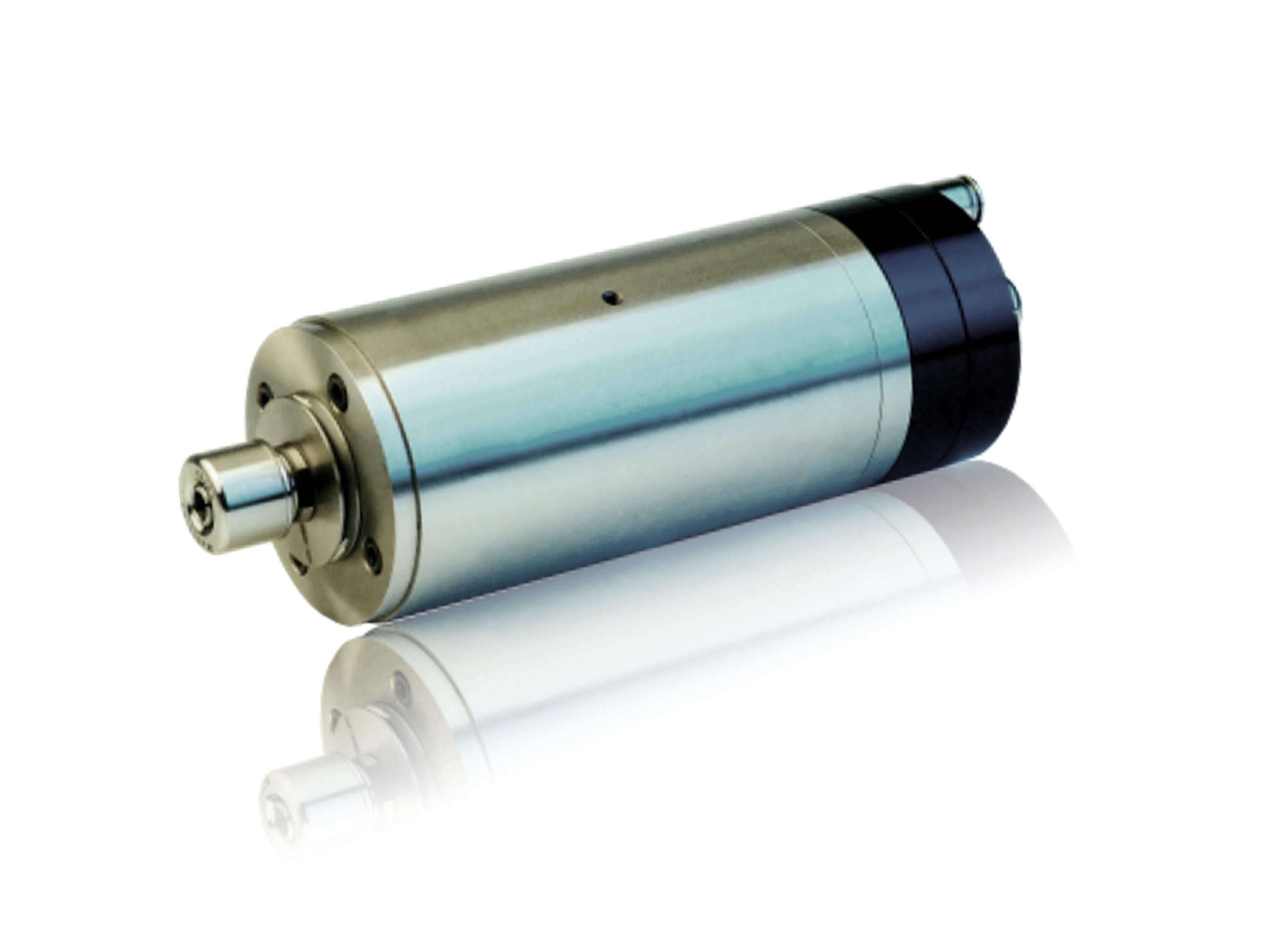

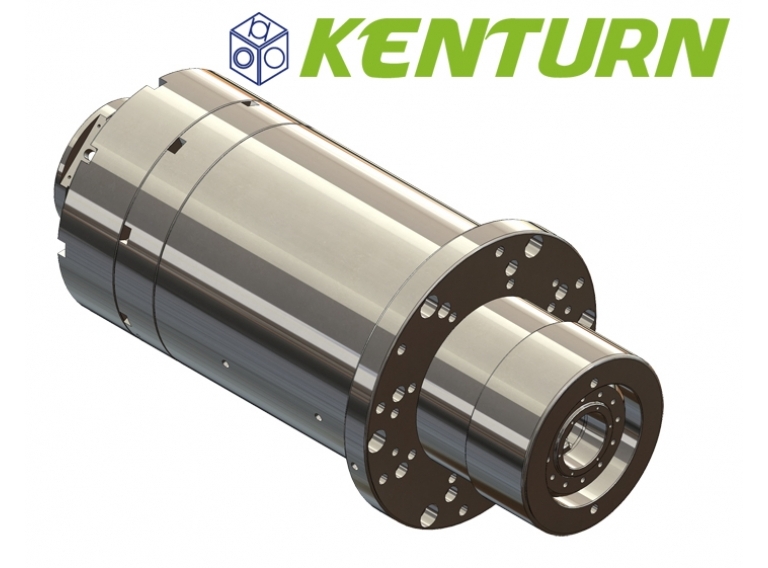

KENTURN NANO. TEC. CO., LTD.

製品の説明 :

Our own manufacturing spindle can fulfill the coolant of axis also inhibit the heat and thermal deformation by using the Germany original OTT HSK-A63 drawbar system. Besides, the oil-air lubricating bearings can stand long-term cutting operation. The spindle, motor power is up to 25KW, speed 18000 RPM, using dualdrive chunk, can be used in vertical machining centers and medium gantry machine.

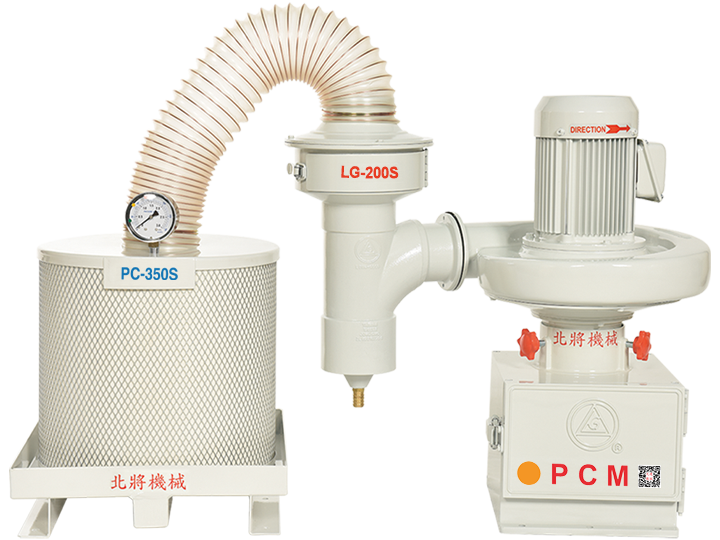

PEI CHIANG MACHINERY CO., LTD.

製品の説明 :

S系列經濟型 產品特色:

● 半油性切削液專用

針對水性切削液設計之HEPA濾材,有效過濾水霧懸浮微粒

● 高效淨化有毒物氣

再過濾油霧回收機餘氣、PM2.5懸浮微粒60%,配合二段式高壓油霧回收機,整體過濾效能達95%

油霧回收機本體特色 :

●機體材質鋁合金成型,重量輕,堅固耐用

●強力高風壓,最大可達320mmAq流量流速穩,過濾效能高

●使用感應式馬達,電量省 散熱快 適合長時間運轉

●結構式原理回收油霧,直立式設計,不震動,低噪音

●安裝容易,不佔空間,使廠內機械移位佈置更容易

●捨棄式濾網,10秒快速更換,保養容易,工安無慮

分離式油煙處理座特色

●標配之壓力錶:可輕易檢知是否有阻塞的情況 、 判斷濾材更換時間

●專利結構設計:由上往下之設計原理,以高風壓加速濾材所吸附的油氣集結快速垂降, 使壽命有效延長

●分離式之設計:因應現場需求,可直接安裝於機台上方或任意位置

●彈性多功組合:可單獨選購或配合任何有動力送風之末端空氣處理

● 免保養易更換:濾材無需保養,分離式之設計使濾材更換更加容易

適用範圍:

CNC車床、CNC铣床、CNC綜合切削加工機、CNC磨床、放電加工機、滾齒機、洗淨槽、防鏽油噴霧回收及會產生

白煙、細油氣、水霧、油霧之各種設備的回收淨化處理。

選配項目:

● 活性碳AC-650 ● 油煙處理器S-350 ●油煙處理器SH-650 ●側掛鐵架 ●直列式四腳架 ●並列式四腳架