展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

3DPRINTING

製品の説明 :

各個行業中的3D 列印- 消費產品設計師、汽車製造工程師、牙科實驗室和無數其他的專業人員都在使用 Stratasys 3D 印表機。 我們的技術正在改變和加快全球設計和製造的發展。 Stratasys 3D Printer 3D印表機正在改變和加快全球設計和製造的發展,3D列印技術的出現是對生產方式的一種革新,它擁有高訂製化模式,能夠為複雜設計降低成本,同時也能提供更低成本的零部件,使企業獲取更高利潤。 各個行業中的 3D列印 3D Printers- 航太汽車製造工程師、醫療創新領域、各類商業用具開發、消費性產品測試、建築模型設計、客製化牙科實驗室、各學程教育推廣和無數其他的專業人員都在使用 Stratasys 3D印表機。 從建模到材料都是關鍵,洽詢普立得科技得知如何正確選擇3D印表機! 及各種列印機、掃瞄機、打標機種類比較與產業應用。

TAILIFT CO., LTD.

製品の説明 :

Taiwan’s leading manufacturer of sheet metal working machines. Tailift CNC turret punch presses are outstanding machines for punching and forming. Our company offers a variety of models with a wide working size ranging to 4980mm. They are ideal for manufacturing a variety of products such as precision enclosures, control cabinets, and aerospace parts.

E-TECH MACHINERY INC.

製品の説明 :

ECG series high precision centerless grinder is different from other competitors, we use spectrum analyzer to precisely the machine base inner ribs and casting thickness for greater rigidity. We offer hydrodynamic alloy bearing spindle with best rotation accuracy, suitable for heavy duty jobs, and drastically increase the spindle longevity.

TOP POWER MACHINERY ENTERPRISE CO.

製品の説明 :

The oil-water separator can separate the slide oil and cutting oil from the water in the water tank of the machine tool, thereby realizing the centralized discharge of waste oil while maintaining clean oil and water for circulating filtration. Features: It can be used without horizontal calibration and has a built-in double-layer impurity interception device to ensure efficiency and safety during operation. It is easy to install and use, and can easily extend the service life of the cutting fluid. It adopts pneumatic drive, which is safer and more reliable. The product has zero consumables and no additional burden.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

X axis travel:

Single movement: 2550 mm (100") inch

Dual movement: 1275 mm (50") inch

YZ axes travel: 850x600 mm (33"x24") inch

※Y axis can be increased to 1300 mm(51") (Option)

※Z axis can be increased to 1000 mm(39") (Option)

Work table: 3100x1600 mm (122"x63") inch

Max. Workpiece: 4100x2050x1250 mm (161"x81"x49") inch

Max. Workpiece weight: 22000 kg

Max. electrode weight: 500 kg

Machine net weight: 29410 kg

Oil level: 110-1000mm (4"-39") inch

Occupy size(LxWxH): 6480x6600x4600 mm (255"x260"x181") inch

Work Table to platen:

600mm Z travel machine: 1138-1738mm (45"-68")

1000mm Z travel machine: 740-1740mm (29"-69")

Filter: 4

Paper filter:8

Capacity:11300 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

TOP POWER MACHINERY ENTERPRISE CO.

製品の説明 :

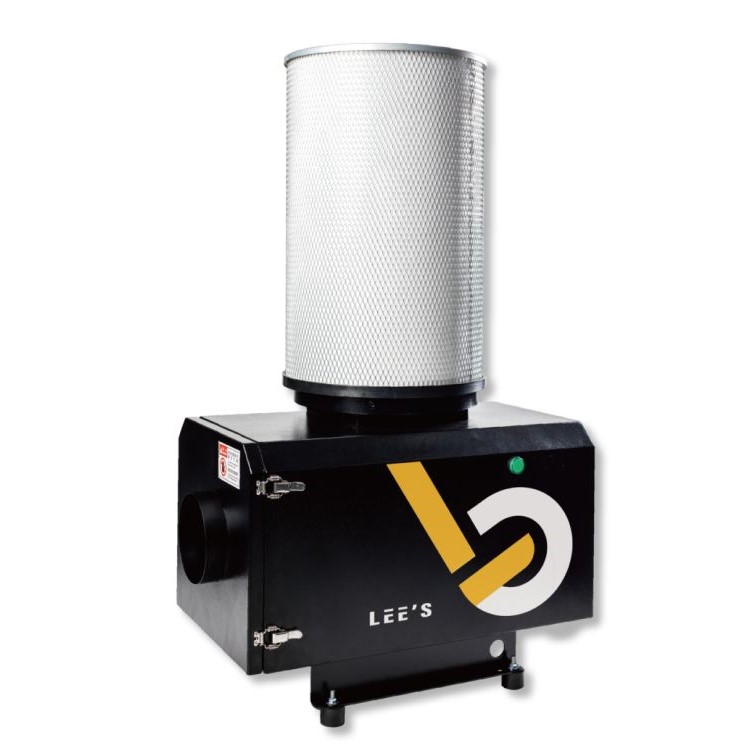

We exclusive patented technology and is committed to developing and producing products that meet global environmental protection goals. The machine is made of all metal and stainless steel materials. From the perspective of environmentally friendly equipment, it realizes the concept of net-zero and low consumables. Using the principle of physical centrifugation, a unique oil throwing device is designed, which can effectively extend the maintenance cycle and increase the filtration rate of oil smoke generated by the processing machine to more than 85%. In addition, the new generation design improves the performance of the machine with the same horsepower by 50%. Under the same efficiency, the power saving rate can be as high as 200% to 400%.

Taiwan TeamA Tech. Co., Ltd.

製品の説明 :

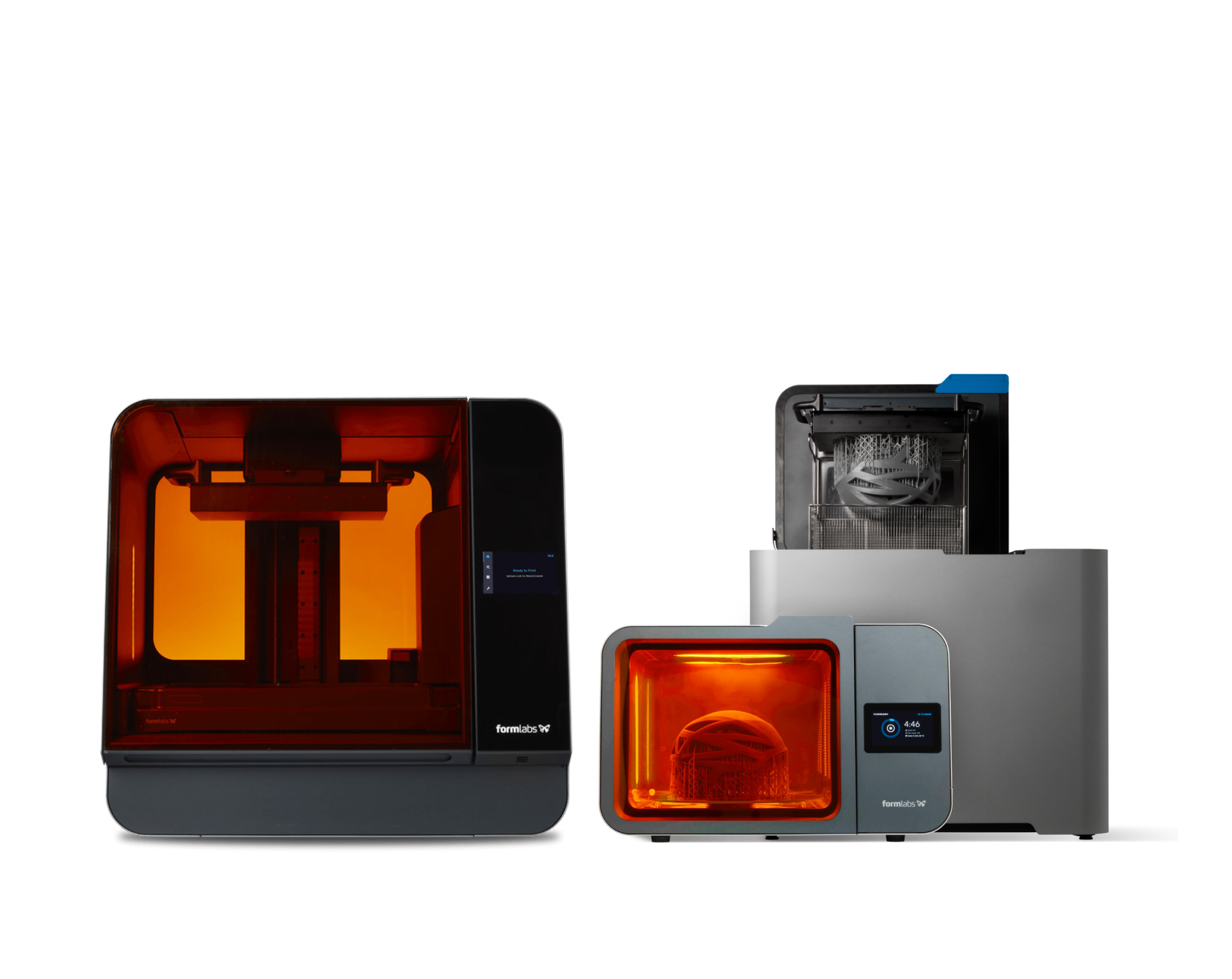

Form 3L為 Formlabs 推出的大型光固化3D列印機,是一款成型空間達擁有達33.5*20*30cm的桌面級3D列印機,讓您的想像力不受限!採用最新專利研發的低應力光固化成型技術(LFS),擁有彈性樹脂槽與封閉式光學模組(LPU)等,大幅增加了機器的可靠與穩定性,精確度、平滑度及透度都大大增加,讓您的大物件也擁有精緻細節!搭配Form Wash L自動清洗機與Form Cure L溫控光固機,以磁力迴旋可一次清洗一個Form 3L平台或是兩個Form 3平台,並使用兩個500W加熱器與大功率紫外線燈全方位高度強化,發揮材料最佳性能!

Form 3L特色包含

1. 33.5*20*30cm 超大列印空間

2. 大型物件也有大大的細緻度

3. 彈性成型槽印大型實心物件也不怕

4. 專利LFS技術配合光學模組使透度平滑度大幅提升

5. 雙卡匣智能給料,安心列印不中斷

6. 高達20多種樹脂滿足外觀、功能驗證需求

7. 輕觸支撐材,好拆不麻煩

8. 繁體中文切片軟體PreForm超好用