展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

PALMARY MACHINERY CO., LTD.

製品の説明 :

For various eccentric circle or non-round shape workpieces grinding purpose, PALMARY develop CNC Cylindrical Grinder Cam Type with CAD/CAM software for easily transfer from workpiece drawing to grinding program. The workhead could offer precise angle control upto 0.1 micron resolution due to the C axis has accurate angle encoder. The infeed axis is driven by linear motor with linear guideway & close loop linear scale, it could avoid the backlash in order to reach high machining precision. Also, it could prevent the reaction force causing by linear motor under the large acceleration and deceleration motion, it could stabilize the grinding process.

MENG YI INDUSTRIAL CO., LTD.

製品の説明 :

The dimension of Drill with Inner-outer Chamfer Tool is from Ø3.0 to Ø25.0. Drilling and chamfering are process on the machine once. The material of drill is tungsten carbide and it could be customized. Replaceable insert could be sharpened.

Video: https://youtu.be/kTbYR3u_lfo

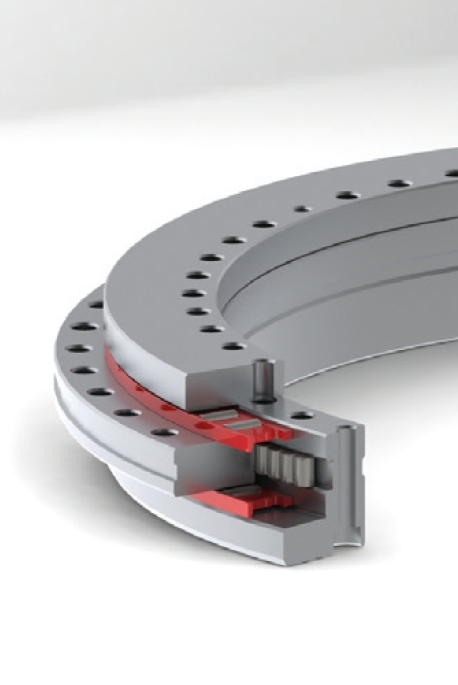

KCW ETERNAL ENTERPRISE CO., LTD.

製品の説明 :

Features: High rigidity, high rotational accuracy, high geometric quality

Compatible with market standard products, short delivery time

The perfect solution for high positioning accuracy requirements:

Rotary tables and indexing plates, integrated processing machines, Milling machines, drilling machines, Machining Center

VISION WIDE TECH CO., LTD.

製品の説明 :

GSF Series 5-axis Gantry Type Machining Center, provided excellent 5-axis simultaneous accuracy performance for 5-axis machining in mold cutting, highly precise contour finishing, milling, drilling, and tapping. Vision Wide manufactured the 5-axis machining center to shorten tool displacement travel and cutting process effectively, and to extend tool lifetime and offer the best choice for composite angle machining. GSF Series had excellent dynamic performance on one-piece structural and equipped high accuracy 2-axis head to achieve 5-axis simultaneous accuracy performance.

•Continuous 2-axis head

•5 axis dynamic rotation synchronization accuracy (TCPM) 0.04mm.

•Built-in Spindle Direct-Driven on B&C axis, 12,000~24,000rpm spindle speed.

•Backlashless driving on B/C axis,Rotation Positioning accuracy ±5”.

•Low table height, closer operating zone, wider door width are convenient design for user.

•Chain type chip conveyor (standard) is able to remove iron chips efficiently.

CAMPRO PRECISION MACHINERY CO., LTD.

製品の説明 :

Campro manufactures a family of Double Column Machining with size up to 5,200 x 3,100 mm travels. The machines offer the highest accuracies of any bridge mill on the market and can machine large parts efficiently with its rigid design. The extended Y-axis has full supported and constructed with a base/bed casting. The PV-XX16 (1,600 mm travels on Y-axis) is one-piece monoblock column structure that is bolted to the bed, delivers rigidity and stability. The PV-xx21 and PV-xx26 have wider door span and bigger machining range, the optional 1,000 mm Z-axis travel is best for attached head requested user.

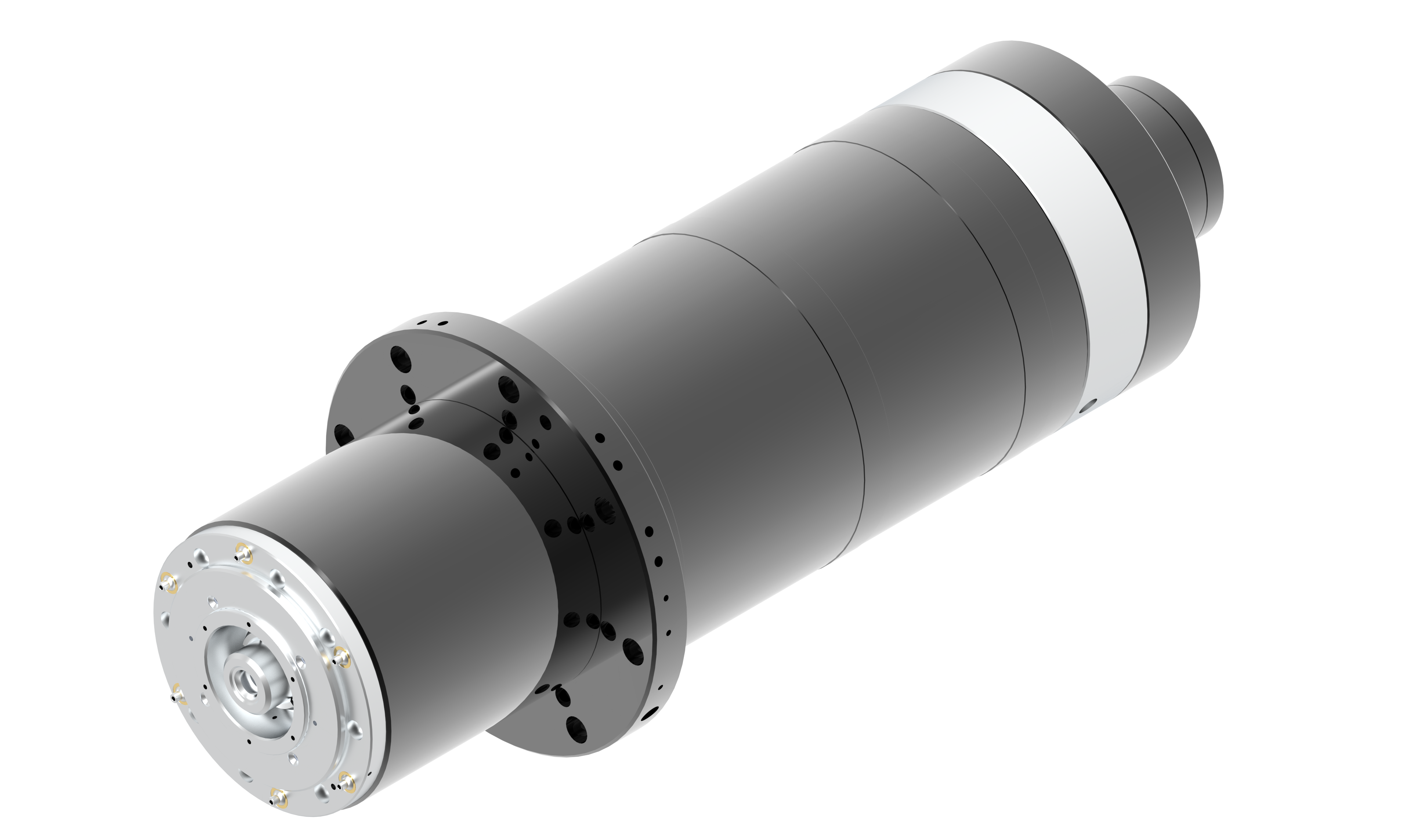

GP MACHINERY CO., LTD.

製品の説明 :

Built-In Spindle

◆ Lightweight design.

◆ After the mandrel is cryogenically treated, the heat variable is small and the machining accuracy is excellent.

◆ The internal cooling system adopts spiral circulation to achieve high-efficiency operation.

◆ The spindle adopts ceramic ball bearings from Europe to achieve optimal power and excellent rigidity.

◆ With standard accessories bearing temperature sensor PT-100.