展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

SCN MACHINERY CO., LTD

製品の説明 :

深絞(深抽)成型油壓機 - SYT series<br />

<br />

Tonnage: 100 - 3000 ton<br />

Bolster Area: 800 x 700 - 4500 x 3000 mm<br />

<br />

SYT 深絞成型機 - 機身採用高張力,中鋼一級鋼板,頂座,底座,形成門型機架精加工.90°導軌八面滑合設計,滑塊上下運動,導向性好,精度好,強度高,滑合面自潤銅襯材質,導軌高週波硬化,研磨加工,永保精度不變.<br />

油壓動力系統,設計於機台後方採用管路板式集積回路設計,並附冷卻系統,效率能完全發揮,保養簡潔。<br />

油溫超過設定55度,馬達自動停止運轉,並發出警報聲,提醒操作者冷卻水異常,確保油封使用壽命<br />

配備獨立式操作控面板,吋動,下降.慢速加壓.快速上昇.等操作按鈕,前方附有緊急停止按鈕,操作容易安全,由壓力表設定出力大小、行程位置調整於微動開關設定。<br />

<br />

符合ISO9001:2015認證

JARNG YEONG ENTERPRISE CO., LTD.

製品の説明 :

1. High rigidity body structure, machine base casting is integrally formed and high rigidity linear guide way, providing stabler, faster and higher precision.

2. Built-in main spindle is with C-axis function, high speed, big power, high precision and low vibration which can make surface of workpiece smoother.

3. Optional:Synchronous rotary guide bushing device, it's suitable for processing long workpiece which can reduce cycle processing time and improve production efficiency.

4. Sub-spindle is with C-axis function, it can work with live tooling for end side drilling, tapping and milling.

5. It can depend on different demand of machining to with or without Synchronous rotary guide bushing device.

6. Axes:Z1/X1/Y/C1/Z2/X2/C2 + 3 sets of live tooling devices (A/B1/B2)

7. Max. 23 tools, can do machining on front side and back side at the same time which can save time for processing.

8. With guide bush type travel is 180mm, min. offal is 150mm. Without guide bush type travel is 310mm, min. offal is 50mm.

CHUAN TAI HYDRAULIC MACHINERY CO., LTD.

製品の説明 :

The oil return filter is mainly installed on the oil return line of the hydraulic system. Various impurities such as abrasive particles generated during the work of various hydraulic components can be blocked by setting the oil return line to filter and avoid returning to the tank again.

G-TECH INSTRUMENTS INC.

製品の説明 :

The performance of the spindle is an important key to processing quality. When you understand the performance of the spindle, you can predict and control the quality of the processed parts. The shape accuracy, roundness, and surface roughness of the workpieces are all related to the performance of the spindle. Only when the spindle is real measuring the accuracy of the spindle at the processing speed of the machine has meaning to the control of the quality of the processed parts, so measuring and understanding the performance of the machine tool, finding the best working speed, determining the warm-up time, even confirm the accuracy of the spindle after the collision.

LION provided this SEA analysis system as early as 1993 to help spindle manufacturers, machine tool factories and processing plants to reduce workpiece defect rate and improve product quality.

★The SEA system complies with the following international standards:

✓ ANSI / ASME B5.54-2005: "Methods for Performance Evaluation of CNC Machining Centers"

✓ ISO230: Test Code for Machine Tools, 3: "Determination of Thermal Effects" 7: "Geometric Accuracy of Axes of Rotation"

✓ ANSI / ASME B5.57-1998: "Methods for Performance Evaluation of CNC Turning Centers"

✓ ANSI / ASME B89.3.4: "Axes of Rotation, Methods for Specifying and Testing"

YI HSIN TECHNOLOGIES CO., LTD.

製品の説明 :

JIHSENSE INDUSTRIAL37JS F200 TOOL HOLDER PULLING FORCE MEASURING DEVICEJS-F200 拉刀力計係結合本公司力量感測器及掌上顯示器而成之高精度拉刀力測試器,使用應變規為感測元件,變形量小,精度高。適用於 7/24 錐度刀把。一體式的設計,簡潔美觀,免除拉線的煩惱;顯示器使用 LCD 顯示螢幕,省電美觀,具高點保持、自動歸零功能,並可設定三種顯示單位,特別設計的省電線路及自動斷電功能,增長電池使用壽命。握把使用高強度鋁合金重量輕易於攜帶:JS F200 is a high-precision tool holder pulling force tester. It use the strain gauge for the sensing element, with small deformation and high precision. Applicable to 7/24 taper spindle. It integrated the load cell, signal processing unit and LCD display, to a compact measuring device. No connector and cable on it, simple and beautiful. Specially designed auto power off function, increase battery life.

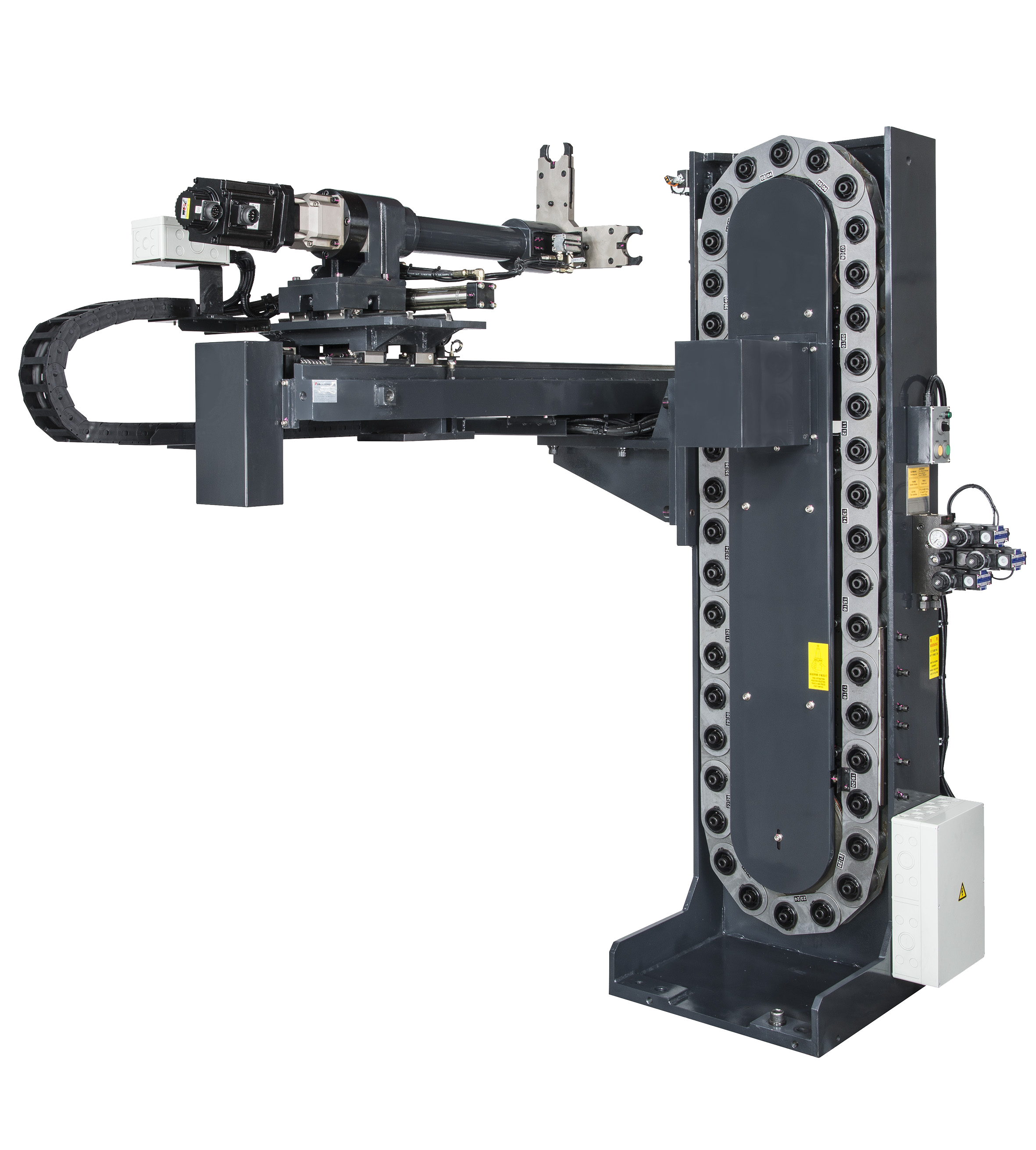

GIFU ENTERPRISE CO., LTD.

製品の説明 :

Applicable Specification:

BT40/CAT40/DIN40/HSK63/CAPTO6

Applicable Model:

Multi-Tasking Machines

1.L-shape arm allows speedy tool changing with short sequence. Besides, low swing loading makes long product service life.

2.The main chain wheel is driven by servo motor, which achieves accurate positioning, fast tool selection and multi-tasking tool management.

3.The long-distance movement is driven by servo motor, which achieves fast and accurate positioning.

4.Expandable tool storage.

GT MARKETING Co., LTD.

製品の説明 :

Designing Is to Deliver A Better Life Experience

Experience design is a coherent journey of using, from exploration and research, innovative concepts to design implementation, the whole process should be taken seriously. In order to achieve this kind of experience design, GTMC has established a UX design team with talents including user research, information architecture, interactive designers, visual designers, web designers, and front-end engineers. The team is diverse, full of enthusiasm, and also paranoid about design.

SHARP ONE CO., LTD.

製品の説明 :

M26AB is of good quality and meets market needs. It solves the

incomplete design of the traditional end mill grinding machine on the

original market. Compared to other brands, M26AB features are as

follows.

Single piece grinding wheel can grind different end gash, first to none.

It can grind variable index and spiral.

Positioning is visible. Grinding intensive and powerful blades is

adjustable.

Grinding carbide flat drill bit.

Grinding chip flutes positive angles.

Standard vacuum can decrease chips spreading, good for health and

machine.

M26AB multi-function machine greatly reduces the cost of end mills

and increases the efficiency. It is the first end mill grinding machine with

standardized positioning, standardized & friendly operation, and multifunction

on the market. These advantages attract users to test our

machines and prove that M-26-AB can help their daily work.