展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

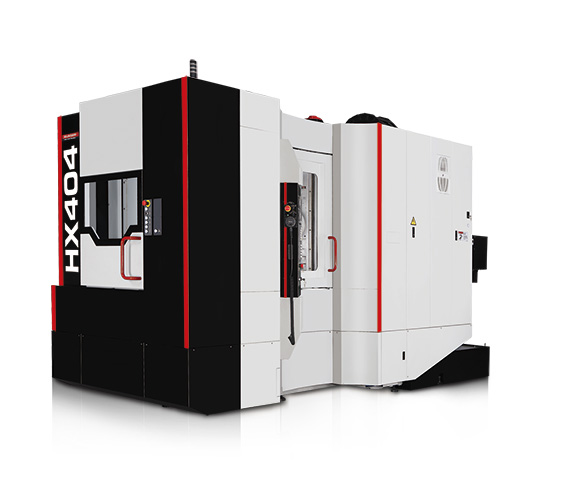

QUASER MACHINE TOOLS, INC.

製品の説明 :

The large Z axis span of HX404 allows the machine to deal with high work pieces and to strengthen machining stability with high rigidity.

The HX404 utilizes W-shaped Z axis telescopic covers to deal with stacked chips, combined with the integrated coolant wash, internal chip augers and external lift up chip conveyor, enhances the management of chip disposal.

In addition, the easy operation and ergonomic accessibility for HX404 allow s operator easily to reach machining work piece, spindle and load/unload station. The HX404 also features small floor space, which makes the best space utilization for clients.

TAIWAN 3AXLE TECHNOLOGY CO., LTD

製品の説明 :

. Processing size: 1300*900mm.

. Metal cutting configuration with Raycus fiber laser, laser wattage 1000W

. Non-metal cutting configuration 320W Co2 laser tube + professional thick plate cutting head

. Professional cutting system, "one-key switch button" on the machine, can easily switch between metal cutting function and non-metal cutting function.

. This equipment is specially designed for cutting a variety of materials, whether metallic or non-metallic.

. We combine the top-standard Co2 non-metal laser cutting machine configuration with the most popular fiber laser cutting configuration currently used in one machine

. Metal cutting head, 10mm focus Z axis direction adjustment, wide cutting range; excellent and stable beam quality, perfect water-cooled structure, advanced dustproof design, effectively avoid dust intrusion.

. Co2 non-metallic laser cutting performance can perform acrylic cutting with a thickness of 30mm. Because the laser head of this model is specially designed, it shows a bright clean surface without ripples after the acrylic cutting of thick plates.

. Optical fiber laser metal cutting performance Stainless steel can be perfectly cut to 3mm without post-processing. For carbon steel, it can also be cut to a degree of 6~8mm. It is the same grade for professional cutting applications.

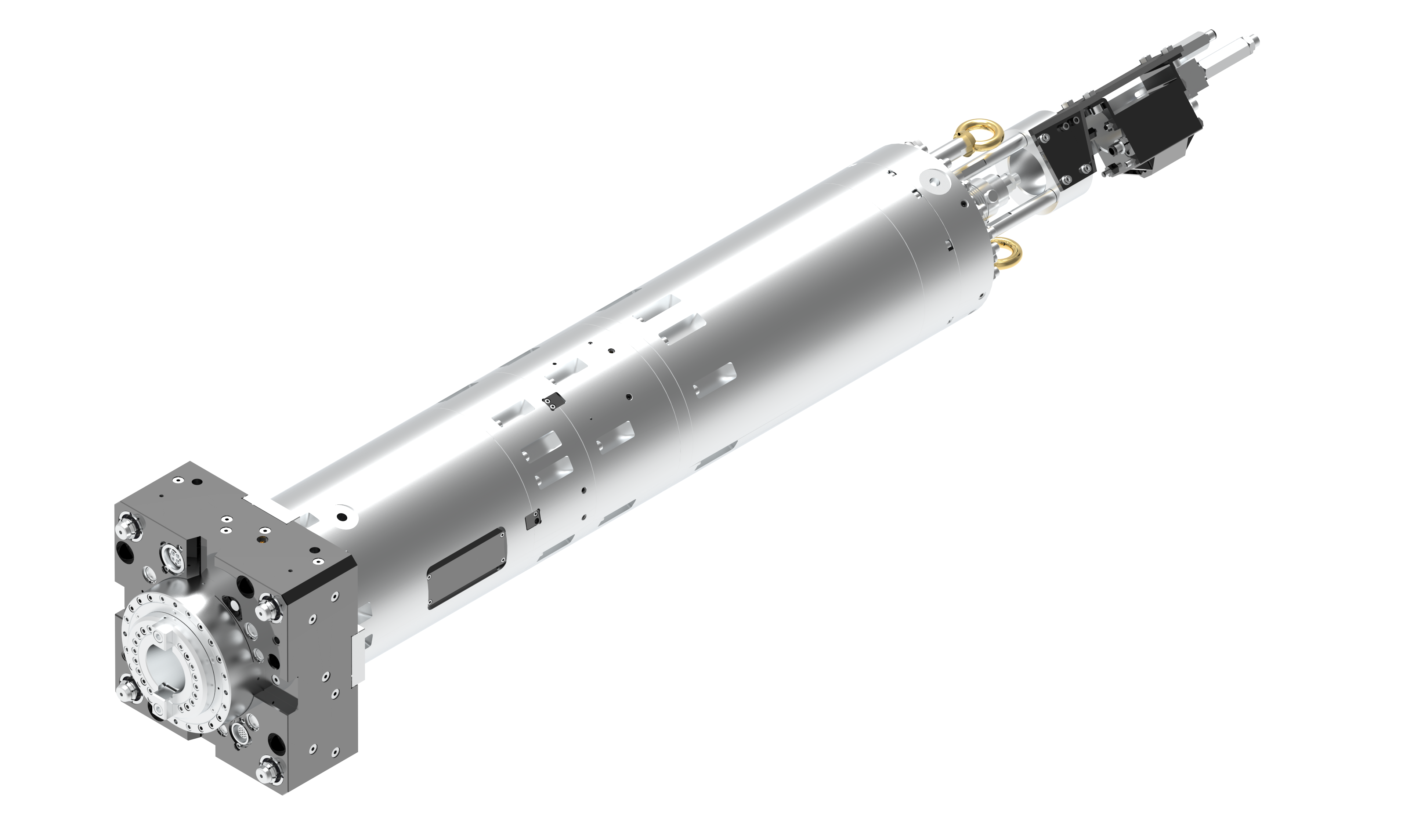

GP MACHINERY CO., LTD.

製品の説明 :

Features:

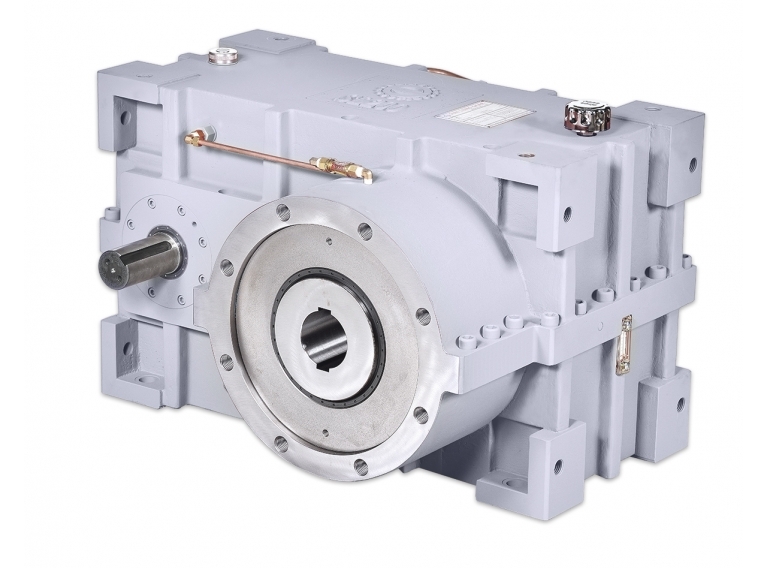

The RGB system (Ram Gear Box) is the most complete solution within this family, with important technological contents, that combines high torque performance in small dimensions particularly appreciated for vertical (gantry or double column) and horizontal axis machine tools. The general characteristics are similar to the RTS

Products:

.Automatic attachment system for the accessories (like heads or extensions)

.Multitasking machining operations.

.Easiness of assembly and maintenance on the machine with:

.Quick connections and couplings positioned at the top of the RAM

.Possibility of easy and quick extracion of the spindle from the front of the RAM.

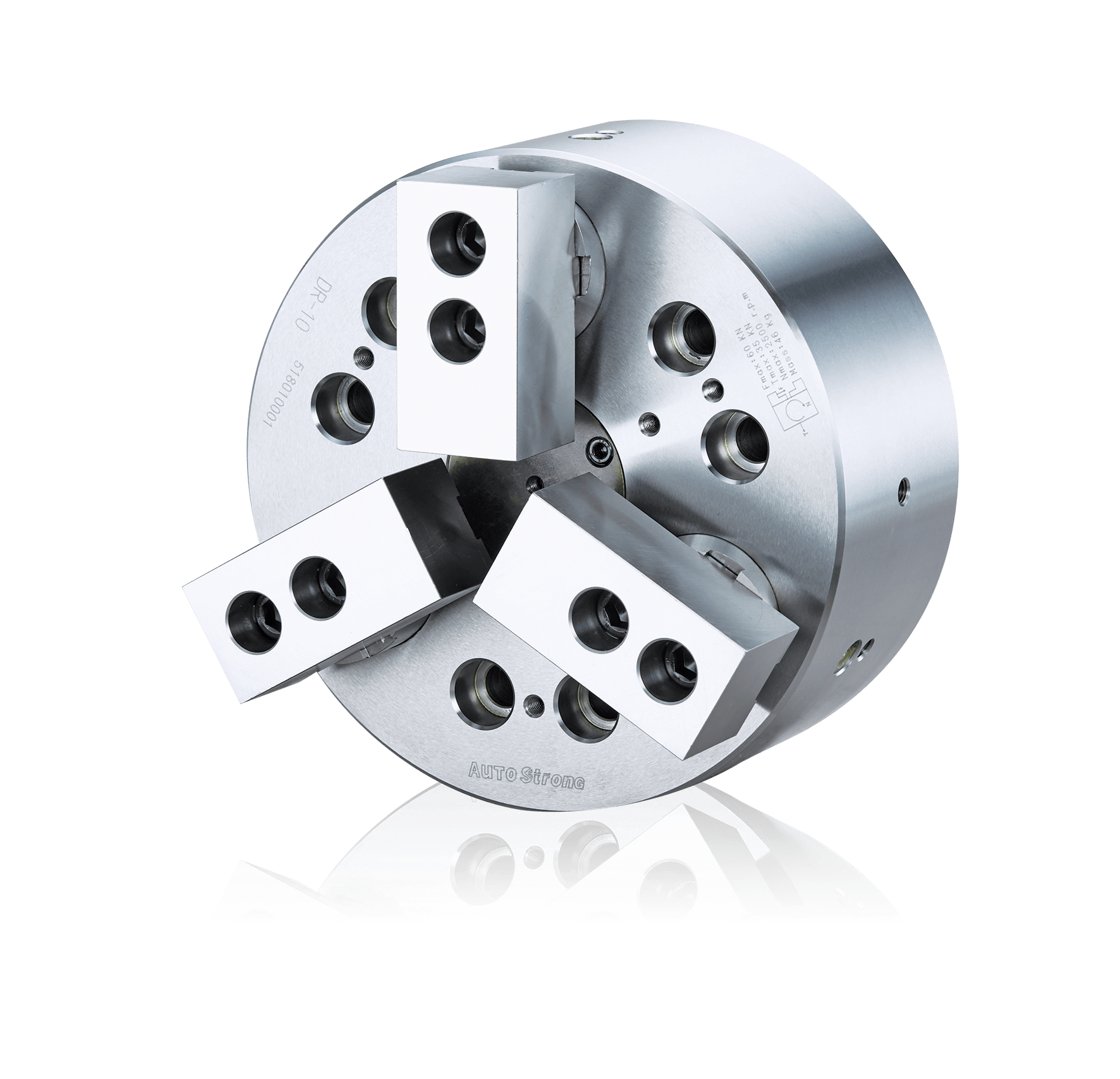

DI CHUN IRON WORK CO., LTD.

製品の説明 :

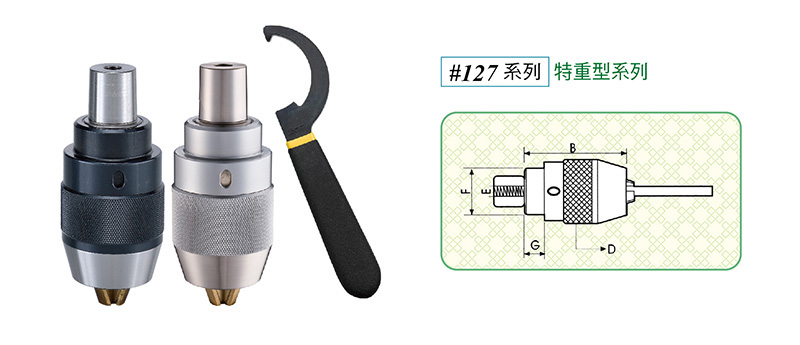

Drawdown power chuck feature of radial clamping will lead to almost no workpiece uplifting displacement; for machining casting and forging part:

1. For the clamped workpiece is oppressed to the surface, chucks are suitable for heavy machining.

2. Chuck Actuators with the cylindrical structure is durable and ensures high clamping repeatability.

3. Accurate self-centering and pull back features are adequate or precise length control machining requirements.

MATRIX PRECISION CO., LTD.

製品の説明 :

GVP-8040 applies the FANUC controller and high speed grinding spindle, through the Matrix developed intelligent conversations window software, it can flexibly output the required tooth profile and grinding parameters. The machining workpieces include involute gears, large-module hobs and cycloidal gears, the high-efficiency and high precision expressed from the products are equivalent to worldwide top brand’s ones. GVP-8040 is your best choice.

MING YANG MACHINERY CO., LTD.

製品の説明 :

This multi-tasking turning center is an advanced machine designed to process precision complex parts in one setup.

Power & Versatility: It has Double Spindles, a VDI/BMT 12 station Turret and a 2nd Y-Axis for back machining with 14 tools for a total capacity of up to 38 tools. This solution with superimposed cutting is a powerful combination of precision and two Y-axes for machining of complex workpieces with extremely fast cycle times.

Front Machining: BMT45 12-Stations, Up to 24 tools, 7.5/11 kW Spindle Power, 55 mm Through Hole.

Back Machining: Gang Tools Slide: 14 Tools, 3 Cross Live Tools, 3 Face Live Tools, 3 OD & 5 ID Tools.

COMETECH TESTING MACHINES CO., LTD.

製品の説明 :

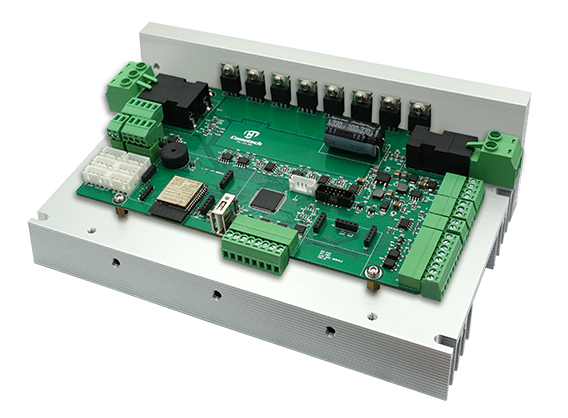

Besides adjusting the motor speed, users can set up detailed motor-related data settings with our C2 series driver. Its multifunctional integrated design is the main feature and advantage for saving costs and reducing external components.

Users can connect directly to the dedicated software for easy parameter tuning and configuration with the built-in Wi-Fi module. An over-the-air firmware update without assembling the driver from devices can improve maintenance efficiency and convenience.

Moreover, the driver features a modular expansion design that allows flexible extensions of communication formats, wireless screen modules, and more to meet various user needs.

※Specification

-Rated Voltage: DC 12~48V

-Rated Output: 800W

-Rated Current: 35A

-Applicable Motor: BDC, BLDC

-Motor Feedback: Hall Sensor, Sensorless; Encoder input signal is available

-Communication Interface: Built-in Wi-Fi module and RS-485; RS-232, CAN Bus for options

-Speed Control: Analog input, Digit input, PWM, Command sources

-Display: 2.8" wireless color touch screen for options

-Software: Equipped with dedicated motor monitoring software which is available to connect with mobile devices (smart phone, pad, notebook, etc.) through Wi-Fi.

※Features

-Integrate multiple functions to reduce the external components' cost

-Monitor the motor's status such as voltage, current, speed, etc. through dedicated software

-Data setting and devices' status monitoring by dedicated software through Wi-Fi connection

-Support different motor control modes (revolutions, distance, operation speed, etc.) and multi-step programmable settings

-Modbus-compatible driver for various host controllers.

-Over-the-air firmware update

-Multiple I/O (open collector) for flexible expansion of different applications

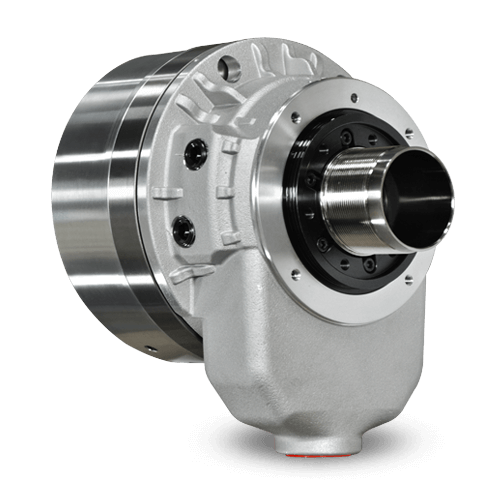

AUTOCLAWS PRECISION MACHINERY CO., LTD.

製品の説明 :

1.Through-hole design facilitates automation center feeding or long bar material processing convenience.

2. Safety Device: Whole series of our cylinders are equipped with check valve as the security device, furthermore, the back-lock design of the cylinder body can strengthen the structure rigidity and decrease the counter-force generated by thrust or pushing force, either the front-lock also can be applied to the cylinder body as well.

3.Short structure design: The short structure design will strengthen the structure,reduce the torque reaction and also decrease both the load of the spindle and the interference when assembling.

4.Light Weight: The cylinder made of high-intensity aluminum alloy and high-strength alloy steel, the structure design can lighten the weight and reduce the rotation inertial

effects,and not only strengthen the structure but also increase the cooling effect.

5.Durability: Adopting high quality steel alloy through hardening treatment and high accuracy professional grinding technology go with superior quality seals, the cylinder can achieve high intensity, high rigidity and well durability features.