展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

YEONG CHIN MACHINERY INDUSTRIES CO., LTD.

製品の説明 :

■ The unique IDD spindle design provides power, speed, and stiffness required for the most adverse machining applications while providing long spindle life.

■ Ceramic bearings help to minimize heat and provide thermal stability improving overall machining accuracy.

■ High precision rotary encoders in the B and C

axes as a standard feature, allowing for the most demanding machining accuracies.

■ ø650 mm table provides stable machining performance with a wide machining area and trunnion support.

WALRUS PUMP CO., LTD.

製品の説明 :

Immersible vertical multistage centrifugal pump, self-priming, co-axial pump/motor design, impellers mounted

on extended motor shaft. Main working parts made by stainless steel.

HON JAN CUTTING TOOLS CO., LTD.

製品の説明 :

● low resistance to prevent vibration and works efficiently

● Various applications for profiling, ramping, and face milling.

● with many cutting edges to save the cost

● Precision coolant design enhances the insert life

diameter: 16mm~50mm

HWE DER MACHINERY AND HARDWARE PTY LTD.

製品の説明 :

Super Micro Grain 0.3u m/m Co8% ,ith high heat resistance and high wear resistance NB coating.

Especially suitable for Alloy Steel、Die Steel、Heat Treatment HRC45~HRC68

MATRIX PRECISION CO., LTD.

製品の説明 :

GHP-3540 applies the FANUC controller and high speed grinding spindle, through the in-house developed intelligent conversation window software, it can flexibly output the required tooth profile and grinding parameter. The machining workpieces include the involute gears and cycloidal gears, the high efficiency and high precision expressed from the product are equivalent to worldwide top brand's ones. GHP-3540 is your best choice.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

X axis travel:

Single movement: 1125 mm (44" )inch

Dual movement: 560 mm (22") inch

YZ axis travel 700x500 mm (28"x20") inch

Work table: 1850x850 mm (73"x33") inch

Max. Workpiece: 2800x1400x700 mm (110"x55"x28") inch

Max. Workpiece weight: 5800 kg

Max. electrode weight: 400 kg

Machine net weight:8350 kg

Oil level: 110-550 mm (4"-22") inch

Packing size(LxWxH): 5430x4600x3090 mm (214"x181"x122") inch

Work Table to platen: 700-1200 mm (28"-47") inch

Filter: 4

Paper filter:8

Capacity:3400 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

THETA PRECISION CO., LTD.

製品の説明 :

產品型號 : THG-120.14<br />

主軸外徑 : 120mm<br />

最高轉速 : 42,000rpm<br />

kW (S1) : 13kW<br />

kW (S6-40%) : 16.9kW<br />

扭力 Nm (S1) : 3.5Nm<br />

扭力 Nm (S6) : 4.5Nm<br />

刀把介面 : D22/38<br />

軸承潤滑型式 : 油氣潤滑<br />

主軸冷卻 : Liquid<br />

主軸長度 : 388.5mm<br />

主軸重量 : 25kg<br />

閉迴路控制 : 客戶選配<br />

中心出水功能 : 客戶選配

SIGMA CNC TECHNOLOGY MACHINERY CO., LTD.

製品の説明 :

Expertise, Innovation, Performance

S5A-4732HH, Special for Difficult-to-Cut Materials processing, Titanium Alloy processing.

Features:

High-Rigidity structure design. Mechanical-type Simultaneous Two-Axis rotary spindle. Warm and gear transmission for B and C axes. With self-made heavy-cutting two-stage gearbox design (Gear Ratio by 1:1.75 and 1:7). Maximum Torque: 1155 N-m.

Unique patented design of the Z-axis spindle rail structure - vibration restrain in machining. It can largely reduce the vibration in machining hard-to-cut material, enhance the machining efficiency, reduce the surface roughness, and prolong the tool’s life. (Model S5A-HH exclusive)

Fully Splash Guarding design. Super large and wide working door design. Fashionable aesthetic and ergonomic safety design.

Specific design of safety guardrail upon the cross column. Convenient for machine maintenance.

Height-adjustable manipulation control box. Suitable for people of different height.

HON JAN CUTTING TOOLS CO., LTD.

製品の説明 :

Our grooving tool and parting-off tool holders are both used with the indexable carbide insert. The selection is determined by the width and depth of the groove and parting-off.shank: 10mm~32mm . cutting width: 2mm~5mm

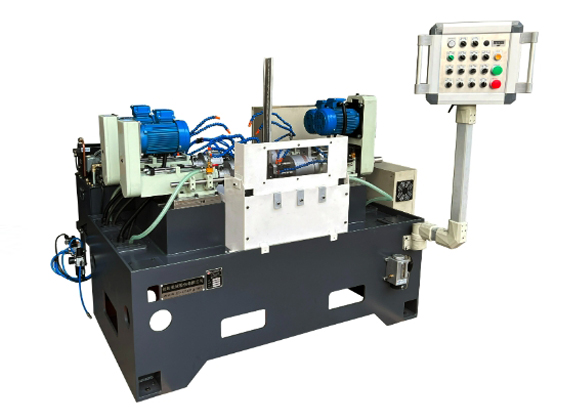

YI CHANG MACHINERY CO., LTD.

製品の説明 :

Linking a made horizontal Unith drilling machine and tapping machine with a hydraulic sliding table, assemble with an automatic loading and unloading system, enables rapid completion of drilling, tapping, and double-sided chamfering tasks.

This setup saves labor and allows precise control of relative positions.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!