展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

COMETECH TESTING MACHINES CO., LTD.

製品の説明 :

If you are looking for a low-cost but with great function performance motor driver, then the C2A series will be a great bargain. This series is suitable for motors below 150W, and the small size occupies no space. Besides adjusting the motor speed, users can set up detailed motor-related data settings with our C2 series driver. Its multifunctional integrated design is the main feature and advantage for saving costs and reducing external components.

Users can connect directly to the dedicated software for easy parameter tuning and configuration with the built-in Wi-Fi module. An over-the-air firmware update without assembling the driver from devices can improve maintenance efficiency and convenience.

Moreover, the driver features a modular expansion design that allows flexible extensions of communication formats, wireless screen modules, and more to meet various user needs.

※Specification

-Rated Voltage: DC 12~48V

-Rated Output: 150W

-Rated Current: 7.5A

-Applicable Motor: BDC, BLDC

-Motor Feedback: Hall Sensor, Sensorless; Encoder input signal is available

-Communication Interface: Built-in Wi-Fi module and RS-485

-Speed Control: Analog input, Command sources

-Display: 2.8" wireless color touch screen for options

-Software: Equipped with dedicated motor monitoring software which is available to connect with mobile devices (smart phone, pad, notebook, etc.) through Wi-Fi.

※Features

-Compact size

-Integrate multiple functions to reduce the external components' cost

-Monitor the motor's status such as voltage, current, speed, etc. through dedicated software

-Data setting and devices' status monitoring by dedicated software through Wi-Fi connection

-Support different motor control modes (revolutions, distance, operation speed, etc.) and multi-step programmable settings

-Modbus-compatible driver for various host controllers.

-Over-the-air firmware update

-Multiple I/O (open collector) for flexible expansion of different applications

PRECISION MOTION INDUSTRIES, INC.

製品の説明 :

In order to meet the market demand for high-speed and high-precision performance in the machinery industry, it is necessary to increase the motor speed and axial feed speed. Therefore, PMI developed a high-speed V-type ball screw to meet this stringent demand.

Feature:

► The Dm.n value has been highly improved.

► lower vibration and noise.

► The size of the nut is reduced by 10 ~ 20 %.

► Improved the smoothness and stability.

HOLD WELL INDUSTRIAL CO., LTD.

製品の説明 :

1.It divides into Axial & Axial Offset & Radial Offset & Angle Adjustable Type

2.Driven Coupling Type divides into DIN1809, DIN5480, and SPUR MT TOEM (Baruffaldi), DIN 5482, HAAS, Mori Seiki…

3.The accuracy is within 0.003mm

4.It can be applied on left and right hand turret.

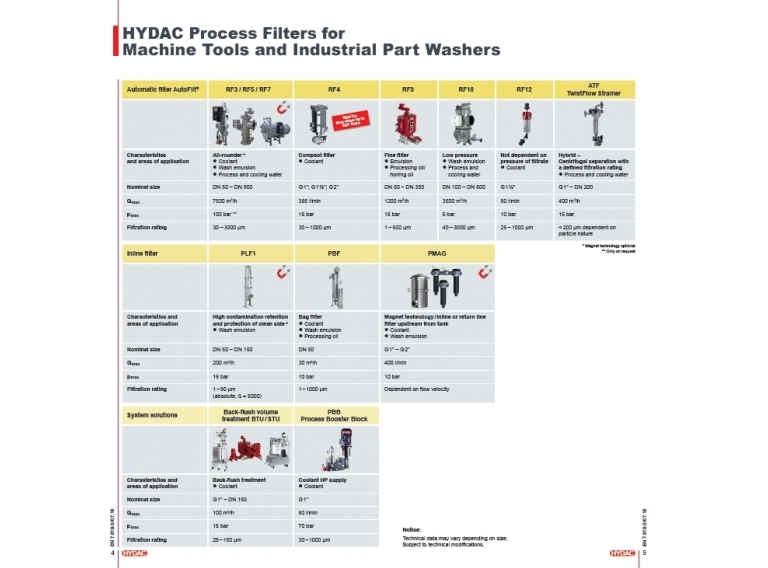

HYDAC TECHNOLOGY LTD.

製品の説明 :

HYDAC專精於系統過濾已累積50年以上的豐富應用經驗,近年來因應CTS中央出水系統<br />

日趨嚴苛的過濾精度要求、壓力自動調節及自動化生產的趨勢,更開發出一系列的自動逆洗<br />

過濾系統、無段比例控制調壓閥並整合成PBB中央出水增壓模組,可大幅縮小安裝空間及減化<br />

配管的複雜度。<br />

<br />

相關系統已經廣或世界知名汽車大廠採用,例如Ford, Chrysler, Fiat, IVECO, GEMA, Linamar, Teksid, Hyundai, KIA.<br />

工具機業者則有COMAU, ETXE-TAR, NTC...等公司採用。<br />

<br />

歡迎在TMTS展覽期間蒞臨HYDAC的攤位(4館德國區-4C145攤位)就近參觀指導。

MATECH INDUSTRIAL CO., LTD.

製品の説明 :

本數控橢圓車床係為解決汽油機與柴油機活塞的中凸變橢圓裙部之加工而設計的。

本機特性

*本數控橢圓車床採用線性伺服橢圓產生器,配合非接觸式0.0001mm超高解析度

回饋系統,具備高響應頻率、高精密度、高剛性等特點。

*由於此設備採用高效能控制核心及極短取樣時間的新一代控制器,可以獲得更快速

且精準的切銷路徑控制。

*本機部份採用全閉環式0.001mm光學尺回饋系統,近一部確保最家定位精度,並能

有效的消除熱干擾。

*新一代整合式橢圓控制器,由於不在需要資料傳輸,因此可以避免因為傳輸而導致的

雜訊干擾或資料遺失。

*編程軟體採用(看圖輸入法)編寫,操作者無須再耗費長時間學習,只要依照活塞圖面

標示的尺寸,輸入安加橢圓控制器即可,型線及相關橢圓路徑則全由控制器處理。

KO-YAN PRECISE MACHINERY CO.,LTD

製品の説明 :

GO-356 CNC Cylindrical Grinding machine combines plunge feed grinding angular feed grinding in one with high investment efficiency. The GO-356 exhibits extraordinary machining accuracy with circularity reaching 0.8 um. It is compactly constructed, occupying a small floor area. Outstanding machine features also include high efficiency, high precision and high productivity.

Machine Features

-Plunge and angular feed grinding.

-Highly rigid machine structure ensures the best possible stability during grinding.

-X, Z-axis are designed with ¡¨V¡¨ and flat slideways.

-Equipped with DITTEL audio sensor for monitoring the grinding quality.

-The tailstock has air floating function.

-Helical grinding and non-circular grinding (optional).

-Grinding speed can reach 50

m/min.

-Circularity accuracy: 0.8 um.

-This machine is equipped with a FANUC Oi-TF CNC controller.

-Selection of various parts loading / unloading devices (optional).

-Measurement system on machine (optional).

-Automatic balancing system can display the unbalanced condition of grinding wheel (optional).

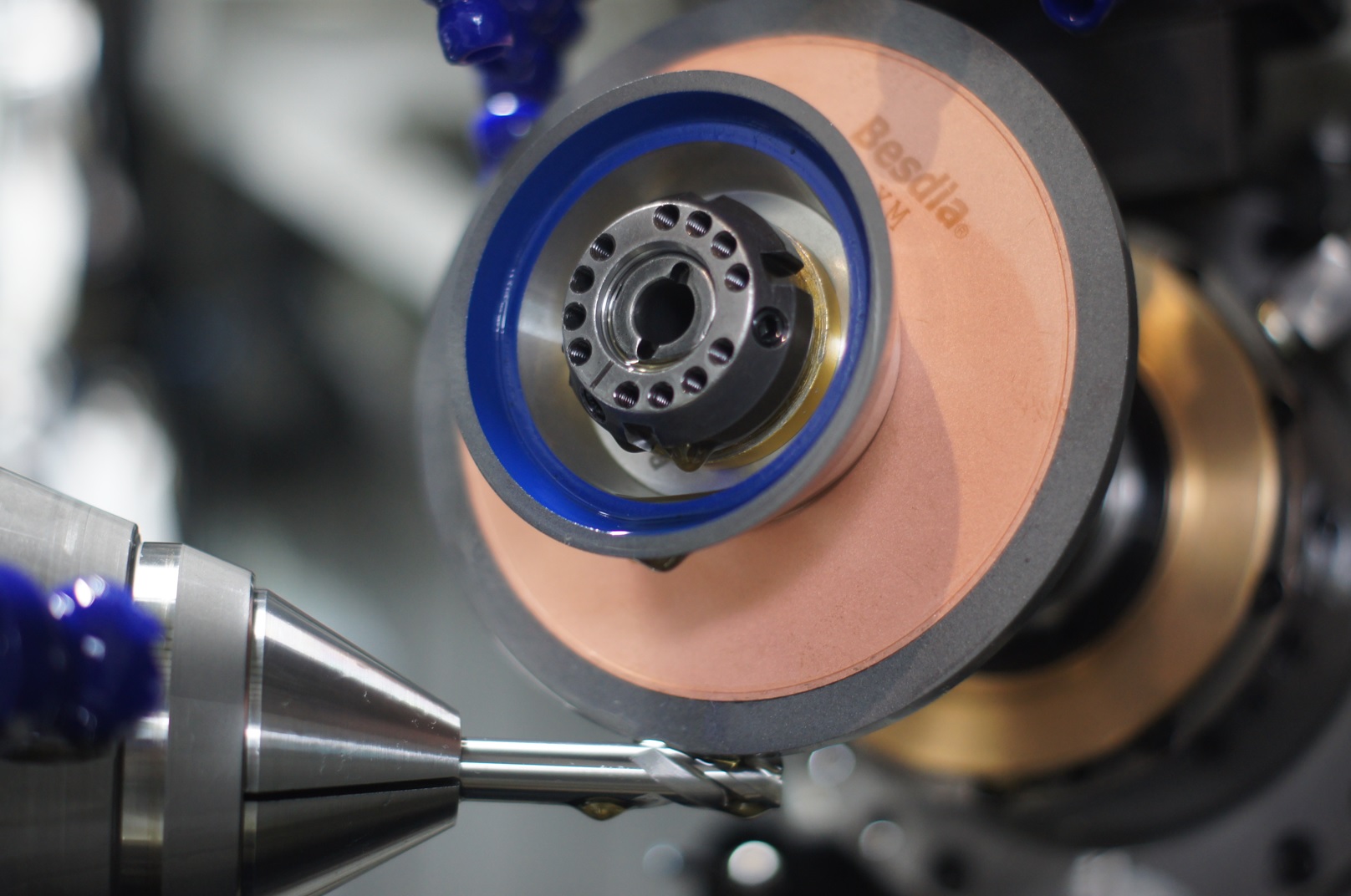

BEST DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

XM Hybrid Bond Grinding wheel (High Performance Fluting)

High metal bonding strength, good heat dissipation, good heat resistance and perfect shape retention make this material ideal for deep fluting, with high processing efficiency and stability. In terms of processing efficiency, product life, heat resistance, heat dissipation properties and wheel strength, it is comparable to imported grinding wheels from major brands. Its primary application is five-axis CNC tool grinding and slotting.

● Ultra efficiency : Exhibits exceptional cutting force. A single feed can reach over 3mm, improving processing efficiency significantly.

● Ultra durability : Fully utilizes the strength of the hybrid bonding method, exhibits good wheel shape retention and is suitable for long-term unattended processing.

● Ultra energy-saving : Displays the dual benefits of retaining cutting force and shape to reduce the spindle load, and eliminate the need for frequent grinding wheel sharpening, thereby conserving energy.

● Ultra cost-effectiveness : Consumables made in Taiwan with imported quality and extremely competitive pricing, reducing the company's costs for these items.