展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

ASMITH MANUFACTURING COMPANY

製品の説明 :

★Handle: FRP has high stiffness and high loading. Load capacity 60 kgf, it is very light and an insulator to electronics. Users will not be frostbitten when the operating temperature is frozen.

Holder: The hole pitch can be adjustable within 18mm, easy to install. Waterproof (IP66). Working temperature is -20℃~150℃, resistance to acid, alkali, and greasiness.

Two ways for install: 1. Inner stationary type. 2. Outside stationary type.

In accordance with RoHS.

➤Material-Handle : Fibre-reinforced plastic(FRP), Black or Silver

➤Material-Holder : Polyamide(PA6-GF33), Black or Silver.

HC FENG CO., LTD.

製品の説明 :

Replenishing Fluid automatically, accurate cutting fluid concentration. One equipment to multiple CNC machining centers. The supply line can be as long as 20 meters.

#Filtration by 3 filters #Sterilization by ozone # Oil-water mixer to precise mixing 0-10% cutting fluid #Stirring device avoid cutting fluid become stagnant water. #oil tank level meter for 50 gallon barrel low level detection.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

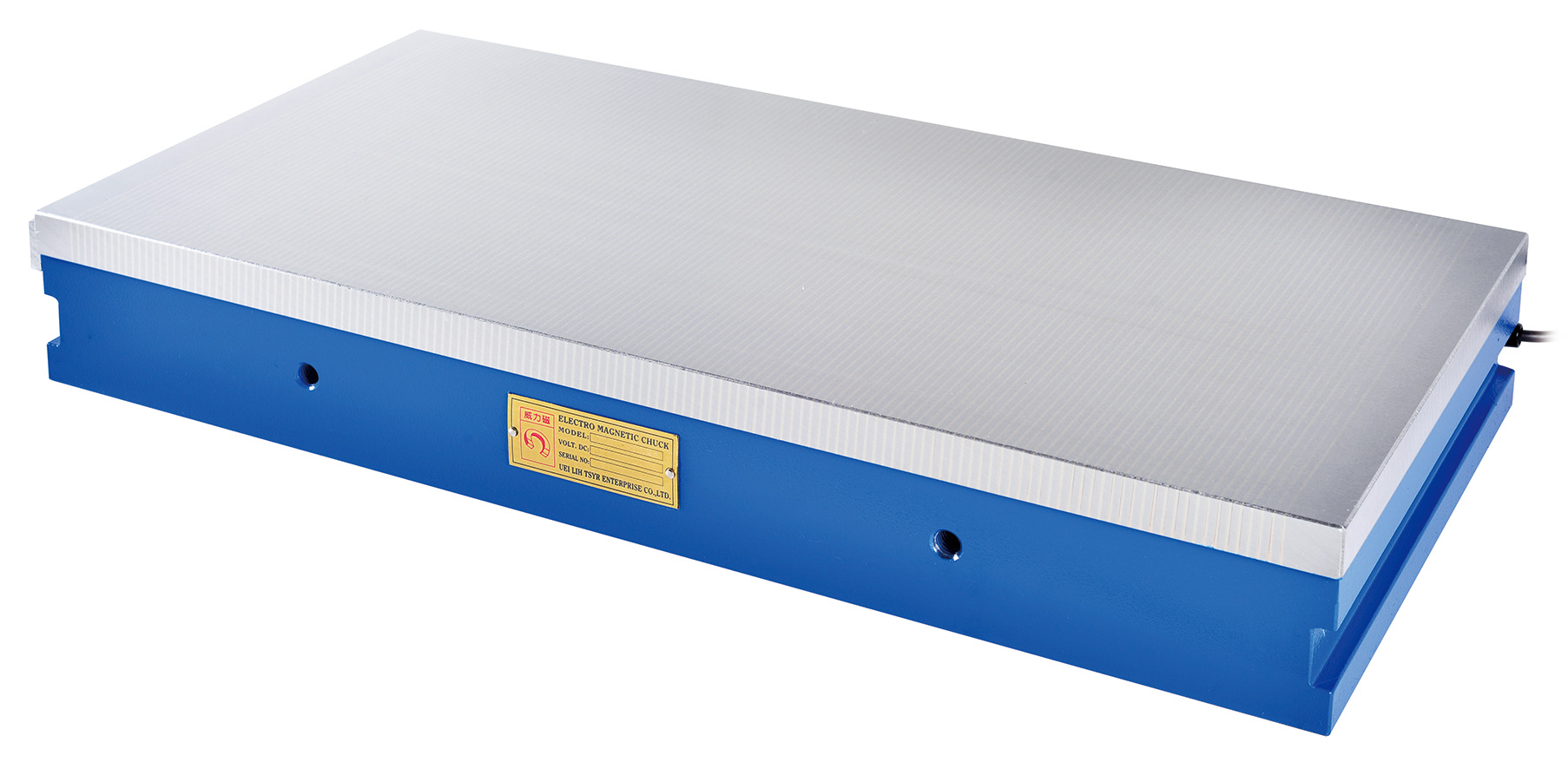

製品の説明 :

X axis travel:

Single movement: 2550 mm (100") inch

Dual movement: 1275 mm (50") inch

YZ axes travel: 850x600 mm (33"x24") inch

※Y axis can be increased to 1300 mm(51") (Option)

※Z axis can be increased to 1000 mm(39") (Option)

Work table: 3100x1600 mm (122"x63") inch

Max. Workpiece: 4100x2050x1250 mm (161"x81"x49") inch

Max. Workpiece weight: 22000 kg

Max. electrode weight: 500 kg

Machine net weight: 29410 kg

Oil level: 110-1000mm (4"-39") inch

Occupy size(LxWxH): 6480x6600x4600 mm (255"x260"x181") inch

Work Table to platen:

600mm Z travel machine: 1138-1738mm (45"-68")

1000mm Z travel machine: 740-1740mm (29"-69")

Filter: 4

Paper filter:8

Capacity:11300 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

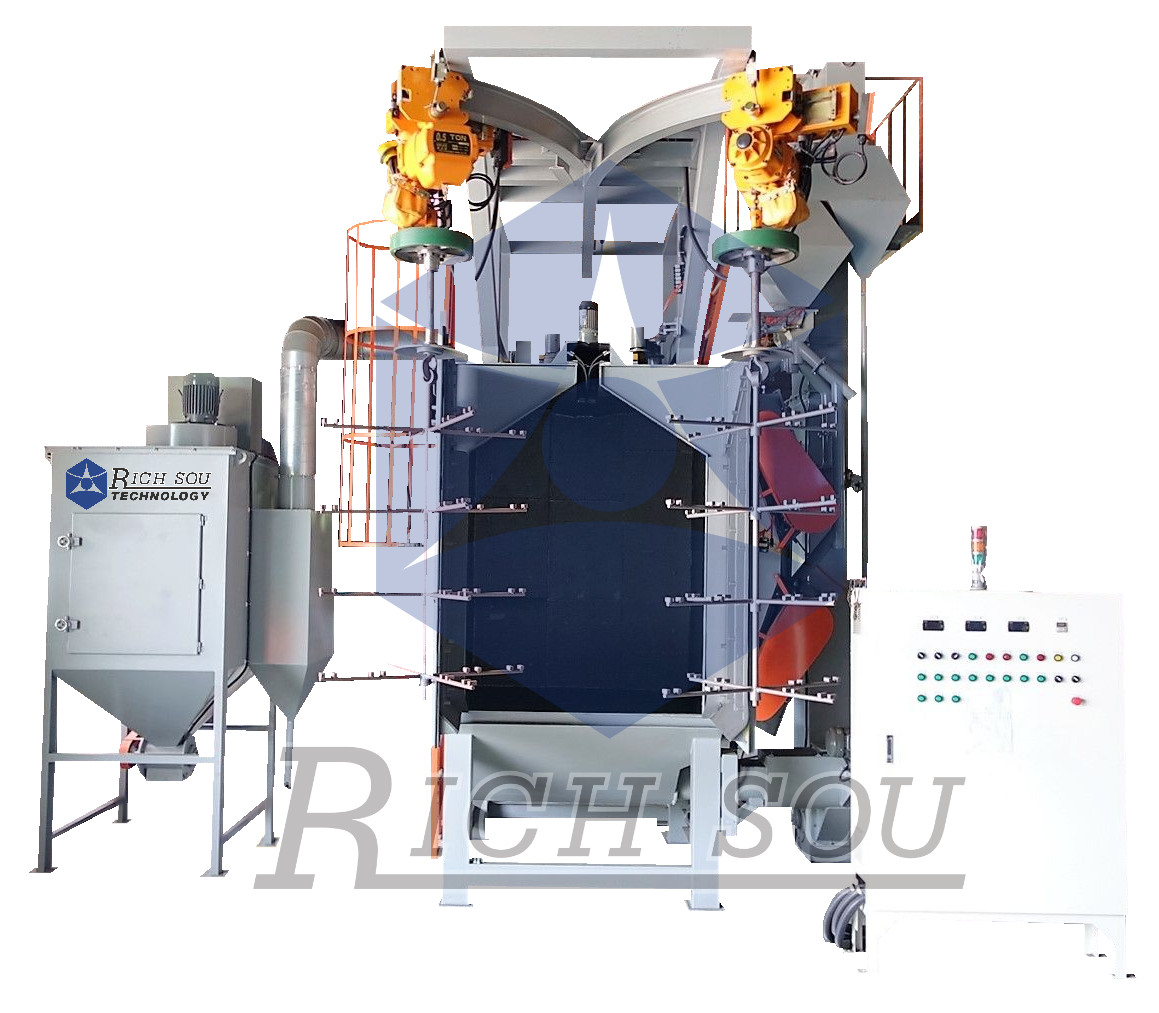

RICH SOU TECHNOLOGY CO., LTD.

製品の説明 :

The door equipped with PENUMATIC valve safe door opening and closing.

The double bevel mechanism has has rail exchange function.When one shaft is performing parts replacement at the outside for saving time.

Steel shot recycling system: Screw Conveyor is equipped with a sieving screen for separating big grits,which will be emitted automatically.

An air operated steel shot separator built on the top of elevator,fully separates steel shot from heavy grits and dust to reduce the consumption of water resisting parts.

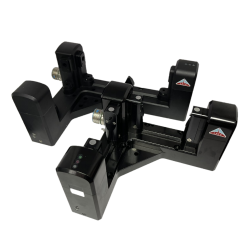

HOLD WELL INDUSTRIAL CO., LTD.

製品の説明 :

1.It can be automatic tool changed. Save time; increase efficiency.

2.Precision P4 class bearing provides accurate concentricity.

3.Cutting direction can be adjusted from 0 to 360 degree. Can easily be set by indicating the datum face.

4.Avoids turning workpiece around to increase accuracy and productivity.

YEU-LIAN ELECTRONICS CO., LTD.

製品の説明 :

We customize CNC MPG pendant encoder, comprise antistatic protection, reversed voltage protection from DC5V to 24V. Rugged model with IP67 dust-proof, oil-proof and waterproof, ergonomics design is much easier to use and smooth handling. Depending on actual needs, axis and multiplication selections can be set; function buttons, emergency stop switch, enable switch, indicator light and wire length are also optionally available.The MPG pendant handwheel is easy to install with multi-conductor cables, and can print the company logo on the manual pulse generator wheel cover. Manual pulse generator box, MPG box, Handle box MPG can choose 100 PPR pull-up, 25 PPR pull up, 100 PPR line driver, 100 PPR open circuit... etc.. Support CNC system like FUNAC, SIEMENS, MITSUBISHI, FAGOR, HEIDENHAIN, LNC, SYNTEC, GSK and other industrial CNC machines.