展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

DAH LIH MACHINERY INDUSTRY CO., LTD.

製品の説明 :

T型結構床台設計。<br />

X, Y, Z軸滑軌均採用鑄鐵批覆合金鋼方式一體鑄造成型,以提昇硬度、耐磨性、吸振性及防鏽性,以重切削能力為訴求。<br />

三軸皆採用預拉式滾柱導螺桿,可減少熱變形,提高定位精度。<br />

齒輪傳動,有二檔變檔功能,在302rpm時即可達到全馬力輸出。<br />

主軸及傳動齒輪採強製冷卻,可降低溫度,提申精度。<br />

主軸頭部與立柱滑道面為8面接觸,以提高剛性,在重切削時獲得最高的穩定性。<br />

主軸頭部為左右兩側對稱設計,可將溫度產生的熱變形降至最低的程度。<br />

穿梭式自動交換工作台,腳踏迴轉裝置。<br />

油壓系統,刀臂夾持自動刀具交換裝置(A.T.C),鍊式雙向迴轉刀盤結構,就近選刀。<br />

浴池式自動交換工作台(6 A.P.C)。<br />

<br />

TAIWAN ASAHI DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

* Processing Method|Cutting Tools

* Applications|Die and Mold

* Customized tool design, lower cutting resistance and torque and better lifetime compared to conventional tools. Reduces the times of tool changes; Suitable for production-related molds.

* Processing Material | NAK80, SKD61, STAVAX, DC53, ELMAX, PD613, HSS, DRM, YXR3, SKHHAP

Graphite, aluminum alloy ADC12, carbon fiber reinforced plastic CFRP, glass fiber GFRP, chemical nickel, copper, oxygen-free copper, various plastic materials PU, etc.

HC FENG CO., LTD.

製品の説明 :

Replenishing Fluid automatically, accurate cutting fluid concentration. One equipment to multiple CNC machining centers. The supply line can be as long as 20 meters.

#Filtration by 3 filters #Sterilization by ozone # Oil-water mixer to precise mixing 0-10% cutting fluid #Stirring device avoid cutting fluid become stagnant water. #oil tank level meter for 50 gallon barrel low level detection.

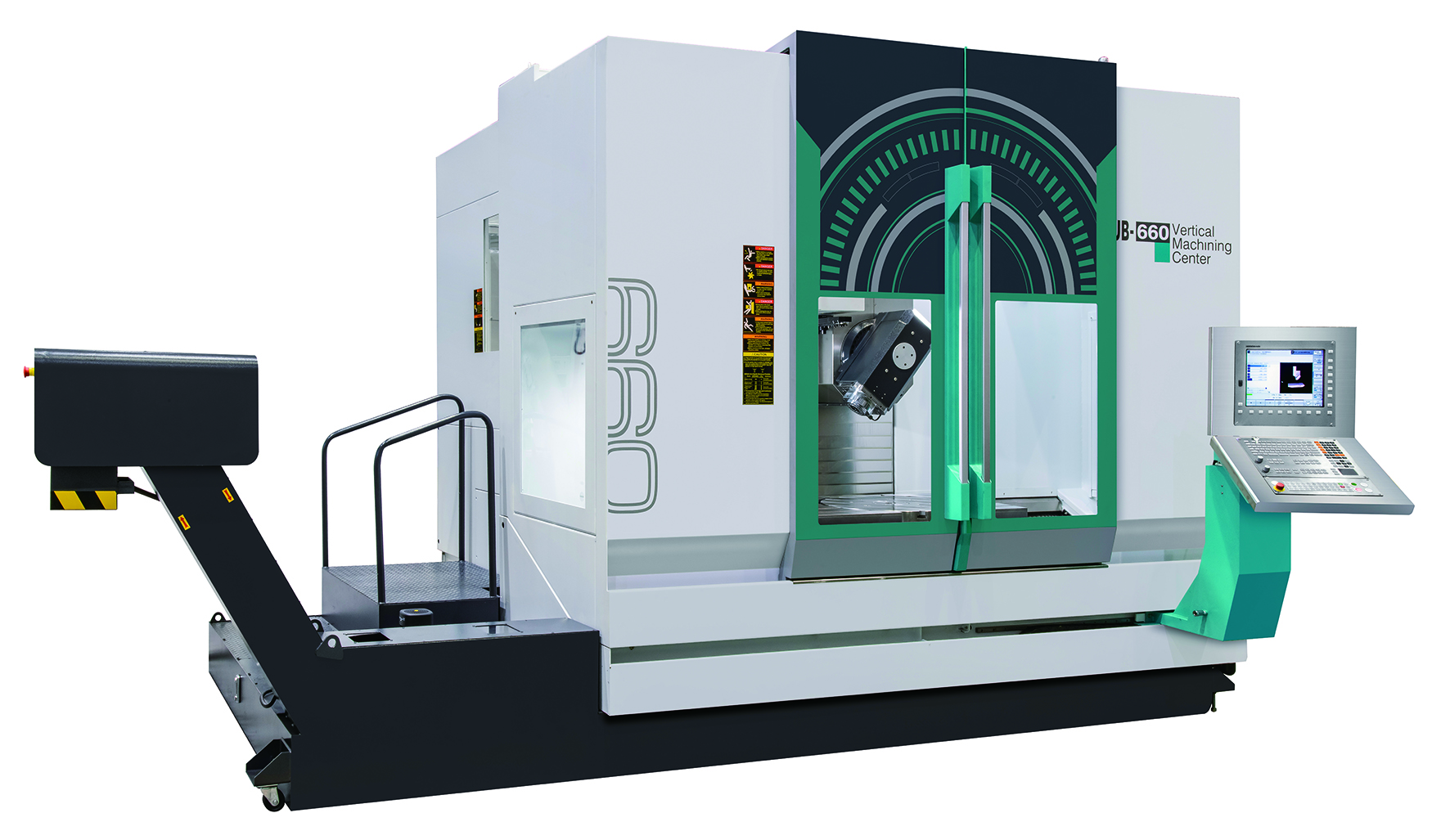

FAIR FRIEND ENTERPRISE CO., LTD.

製品の説明 :

★Moving column structure :

The M-shaped structure increases anti bend and anti-torsion of the column The counter-weight is supported by the pneumatic cylinder. The shape of the column is similar to the pyramid to increase the stability for moving.

★One piece base structure :

The rigidity of structure is good. The outer shape is not complicated, it is easy for machining. The internal structure adopts the box type design to increase the bearing capacity.The round shape hole is easy to clear sand and increase force flow. The work tableadopts the high and low rail design to increase the rigidity.

★Rotary spindle head structure:

Reduce the interference machining area.

★Modular design :

By changing the column head of the column, etc., the customer can have a variety of opportunities to choose from.

★Turning and milling function(OPT)

Shorten the product manufacturing process. To improve the production efficiency, accuracy and reduce the clamping times and floor space. It can be used in aerospace parts and medical equipment precision molds.

CIMer Tech co.,Ltd.

製品の説明 :

Distributed data management

Store, protect and deliver your most important messages

CIMer is a system specially built for the period from product development to mass production. From business orders, CAD product design, material creation, process review, and project management, it can be tracked and searched through any device. As long as you have a browser, you can Can participate in inspection and review of product design and development work.

system structure

Each region establishes its own Vault Server, and files will be synchronized between Vault Servers. Users can access the local Vault Server when accessing files. Users do not need to obtain the original CAD drawing files. CIMer provides converted graphics viewing formats (3D HTML/2D PDF), which can reduce the consumption of web page resources during viewing and improve transmission efficiency....

project management

Provide dynamic information on multi-project management at each stage during product development, such as Gantt charts, to assist the product development team in focusing on product development and improvement, and provide relevant timetables, human resources, output overview and distribution development periods during the period. , achieve better planning and utilization.

Design data and graphics management

Multi-CAD integration platforms, including drawing configuration, properties, versions, version management, combined drawing structures, parts and specifications/file associations of AutoCAD, zwCAD, Creo, Solidworks, Solid EDGE, Inventor, ZW 3D, NX, CATIA, etc., such as Approving documents, document version management, HTML format model viewing, 2D PDF document viewing, sharing drawings, BOM information based on design combination drawings...

Material Management Parts BOM/EC

After the product drawing design is completed, it enters the engineering proofing stage and related material information collection and management. Drawing files, material number correspondence, material attribute management, version management, association and viewing of materials and files, material BOM, automatic generation of material numbers, shared materials, etc...

Sign-off process management

Provide process system customization, and allow multiple people to collaboratively review all work that requires mutual notification, recognition, and review during the product development process. It is used at the review and notification level of the process and can be flexibly applied to the work processes of different departments and personnel.

Network collaboration

CIMer Web provides data viewing in non-Windows environments and implements the basic principles of ESG. Any device with a browser can participate in online process progress, such as inspection and review of product design and development work, paperless factory, post-engineering EC design change management from direct access of design drawings to manufacturing cells...

Message Center

Similar to the Outlook mail management function, it provides a message management center to manage notification messages, quickly jump from messages to related project work, and at the same time send emails to the mail server...

Over 20 years of experience in CIMe system development.

Over 300 case studies.

Visited more than 1,000 customer needs.

More than 200 customer satisfaction cases.

The CIMer system helps shorten your product time to market and significantly saves production costs and hidden losses.

TONGTAI MACHINE & TOOL CO., LTD.

製品の説明 :

‧The VP-12 combines the advantage of a smaller footprint with a large internal machining space, equipped with a high-speed spindle to meet the requirements of efficient and precise machining.

‧Direct-drive spindle BBT-40 provides a high rigidity and high efficiency.

‧The tool magazine allows for flexible tool placement and pre-selection, coupled with a high-speed ATC mechanism to reduce non-cutting time, showcasing efficiency similar to drilling and tapping machining centers.

‧High quality spindle and high rigidity structure design subject to high standards of machine accuracy to achieve good cutting performance.

‧By Tongtai production system, we check every detail process from design, manufacturing, assembly and QC.

YIH KUAN ENT CO., LTD.

製品の説明 :

The CNC Milling Head can tackle all sorts of critical processes, such as rough milling, finishing milling, boring holes, and much more. It's easily compatible with a number of different machines, like computer gantry milling machines, machining centers, and so on. Don't let small spaces or tight curves slow down your projects - the CNC Milling Head is compact enough to fit even into the most complex of workspaces. Plus its precise performance ensures that you get results exactly how you need them - every time. With the CNC Milling Head you can take your machining to the next level while saving time and money in the process.

1. The IK milling head, which fits your current milling machines and special purpose machines, can take place of your current milling heads and upgrade your machines.

2. This product with gear-type construction is very powerful and can creat a maximum machining efficiency for you

3. Spindle speed change has high and low two stage.

4. This product can be installed to a computer-controlled vertical milling machine and a special purpose machine.

5. This products doesn't include a servo motor or servo controller.

6. The IK CNC milling head series has three kinds of products.