展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

GT MARKETING Co., LTD.

製品の説明 :

A professional video not only aims to bring a visual impact, but also can shape the audience's image for the company and the product, thereby generating more benefits.

GTMC has always introduced the most advanced shooting equipment and with the most professional and dedicated service team to assist Taiwan's small and medium-sized enterprises in the production of multimedia videos. From planning, copywriting and scripting, executive production, photography, lighting, post-production editing, 3D animation design to 2D special effects design, etc., we have recruited various professionals across fields to assist companies for different video shooting needs and styles. Creating the most insightful company image video and product introduction video combining with GTMC online marketing experiences carries out the most efficient promotions for customers.

The use of 4K high-quality video recording system combined with 3D computer animation can clearly and completely present the most complete information of companies, products, and services, crossing the distances and limitations of time and space, allowing global buyers to immerse themselves and deepen their impressions.

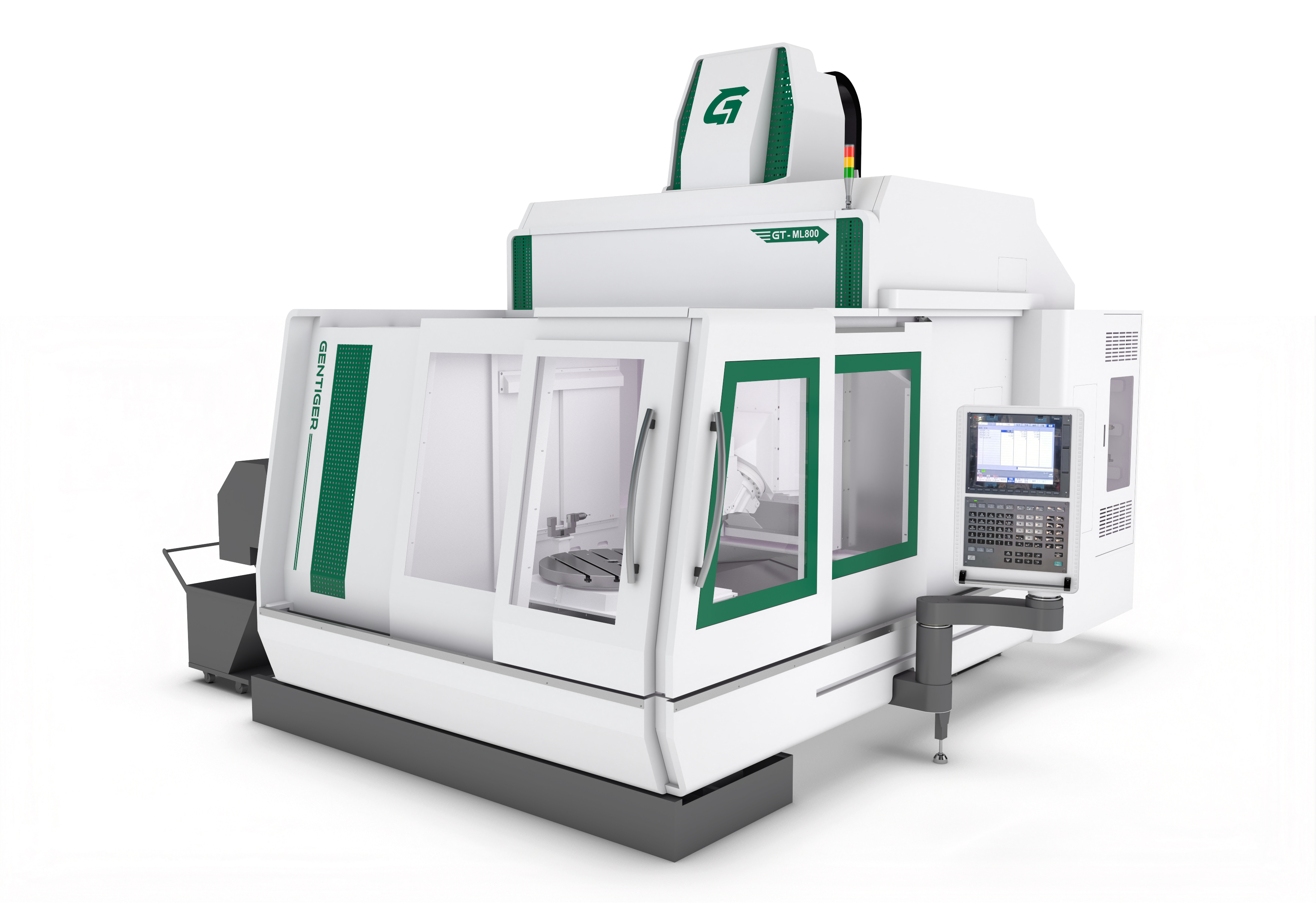

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

製品の説明 :

• Closed-type double-column structure, it increases structure dramatically increases the structural rigidity of the machine and maintains extraordinary stability at all times.

• Roller-type linear guideway on three axes, it achieves high loading resistance, high rigidity, long service life, low thermal growth, and low noise.

• Three linear guideways on the Y axis, it provides more stable support for the spindle head, which contributes to upgraded stability in machining.

• The 45° vertical horizontal swiveling head is applicable for both vertical and horizontal machining, increasing flexibility in machining applications.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

X axis travel:

Single movement: 1125 mm (44" )inch

Dual movement: 560 mm (22") inch

YZ axis travel 700x500 mm (28"x20") inch

Work table: 1850x850 mm (73"x33") inch

Max. Workpiece: 2800x1400x700 mm (110"x55"x28") inch

Max. Workpiece weight: 5800 kg

Max. electrode weight: 400 kg

Machine net weight:8350 kg

Oil level: 110-550 mm (4"-22") inch

Packing size(LxWxH): 5430x4600x3090 mm (214"x181"x122") inch

Work Table to platen: 700-1200 mm (28"-47") inch

Filter: 4

Paper filter:8

Capacity:3400 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

ASMITH MANUFACTURING COMPANY

製品の説明 :

Asmith is a Taiwan professional industrial hardware manufacturer in R&D / Manufacturing / Marketing. Asmith's present facilities are certified for ISO 9001:2015 International Standard. We insist to use the original raw material from Taiwan or Japan, not to use recycling material, and produce RoHS-compliant and high-quality industrial hardware components. Product items are Hinges, Lock latches, Draw latches, Leveling feet, Casters, Lid stay holders, Door gaskets, and Digital(electronic) torque wrenches. Applicable to the semiconductor industry, ultrasonic spray machine, sheet metal, food Machinery, electronic machinery and equipment, machine tools, industrial power cabinets, rail vehicles, chassis cabinets, etc.

YIH KUAN ENT CO., LTD.

製品の説明 :

The CNC Milling Head can tackle all sorts of critical processes, such as rough milling, finishing milling, boring holes, and much more. It's easily compatible with a number of different machines, like computer gantry milling machines, machining centers, and so on. Don't let small spaces or tight curves slow down your projects - the CNC Milling Head is compact enough to fit even into the most complex of workspaces. Plus its precise performance ensures that you get results exactly how you need them - every time. With the CNC Milling Head you can take your machining to the next level while saving time and money in the process.

1. The IK milling head, which fits your current milling machines and special purpose machines, can take place of your current milling heads and upgrade your machines.

2. This product with gear-type construction is very powerful and can creat a maximum machining efficiency for you

3. Spindle speed change has high and low two stage.

4. This product can be installed to a computer-controlled vertical milling machine and a special purpose machine.

5. This products doesn't include a servo motor or servo controller.

6. The IK CNC milling head series has three kinds of products.

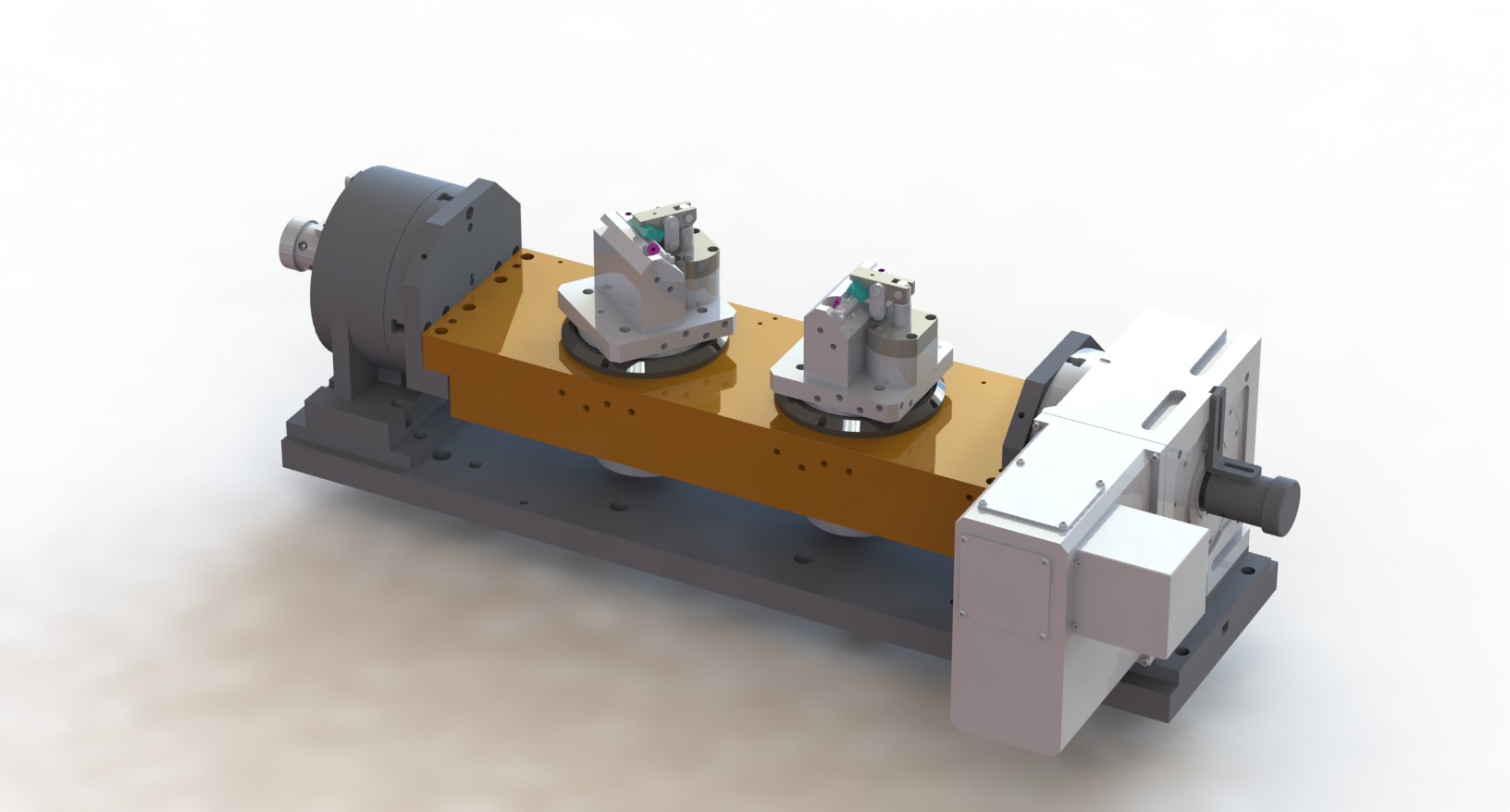

YI CHANG MACHINERY CO., LTD.

製品の説明 :

This model is a Customized Machine that integrates a cam indexer. It connects a drilling machine and a tapping machine, achieving a one-time completion of drilling and tapping.

The machine's uniqueness lies in its advanced pneumatic clamping automatic feeding system, allowing operators to easily complete tasks and reducing operational burden.

Not only does this enhance work efficiency, but it also makes work precision easier to control.

In the pursuit of efficiency in modern manufacturing, our machine ensures operational simplicity, allowing you to focus more on the precise adjustments of your workpieces.

This video demonstrates how it achieves a one-time completion of drilling and tapping, providing higher work precision.

If you have any thoughts or inquiries about our machine, please leave a comment below or call our company. We look forward to engaging and communicating with you!