展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

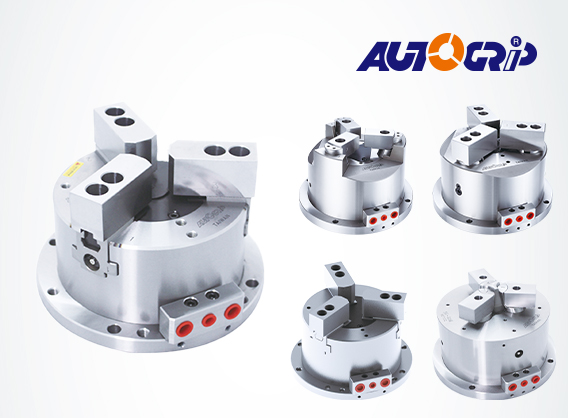

AUTOGRIP MACHINERY CO., LTD.

製品の説明 :

For stationary chuck, there are pull back, pull lock, thru-hole/non-thru-hole stationary chucks in the category.Multi-plate.4-plate(MP4)=>

For milling machine / machine center.

Allow simultaneous machining with up to 4 grippers.

(Order can be customized for 2,3,6 grippers).

Work with SP/SD/SU/SE vertical chuck.

Driven by Hydraulic or Pneumatic.

Individual circuit for each chuck.

Special design and reduce the height of working surface.

Lock valve unit (option).

Air tight detection function(option).

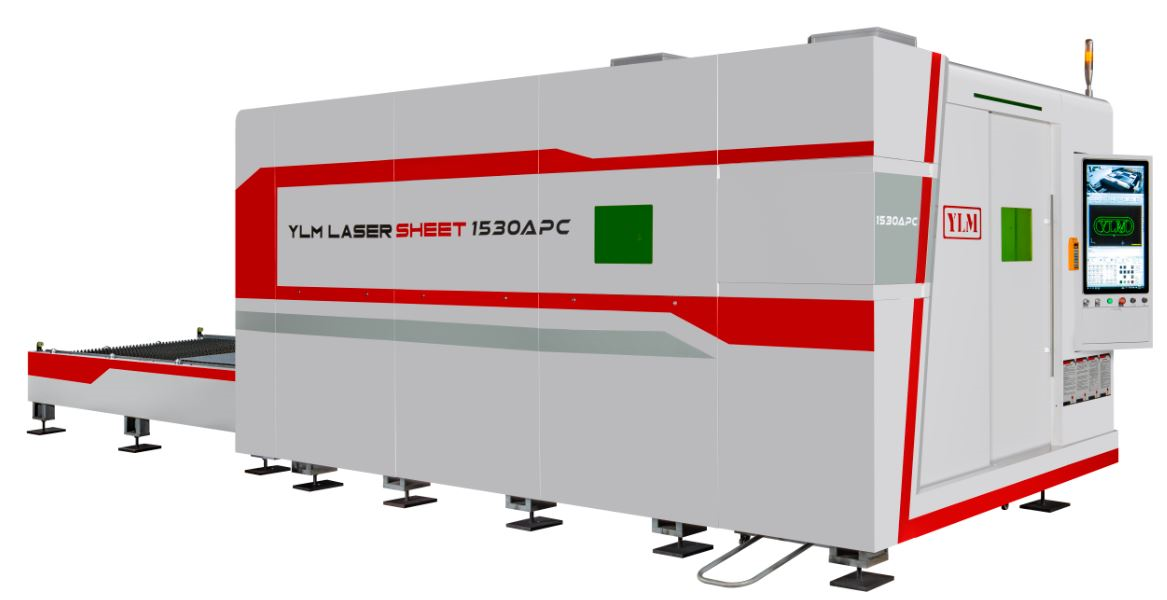

YING HAN TECHNOLOGY CO., LTD.

製品の説明 :

Suitable for cutting various metal sheets

■Maximum cutting thickness of metal sheet varies with the laser power.

■Upon customer request, the machine can be designed with a work piece platform as mechanism(optional). It helps to reduce work piece loading/unloading time, which in turn upgrades operation efficiency.

■Large laser power, high efficiency and high productivity.

■Equipped with an intelligent digital controller featuring humanized control, which is easy to learn and operate.

■The specially designed software allows the operator to design the graphs on characters with ease, then machining can be conducted immediately.

■Enclosed splash guard

■Fast machining, power saving, outstanding safety protection, low trouble and easy maintenance.

For cutting commonly used metal sheets such as:

■Carbon steel sheets

■Alloy steel sheets

■Galvanized steel sheets

■Stainless steel sheets

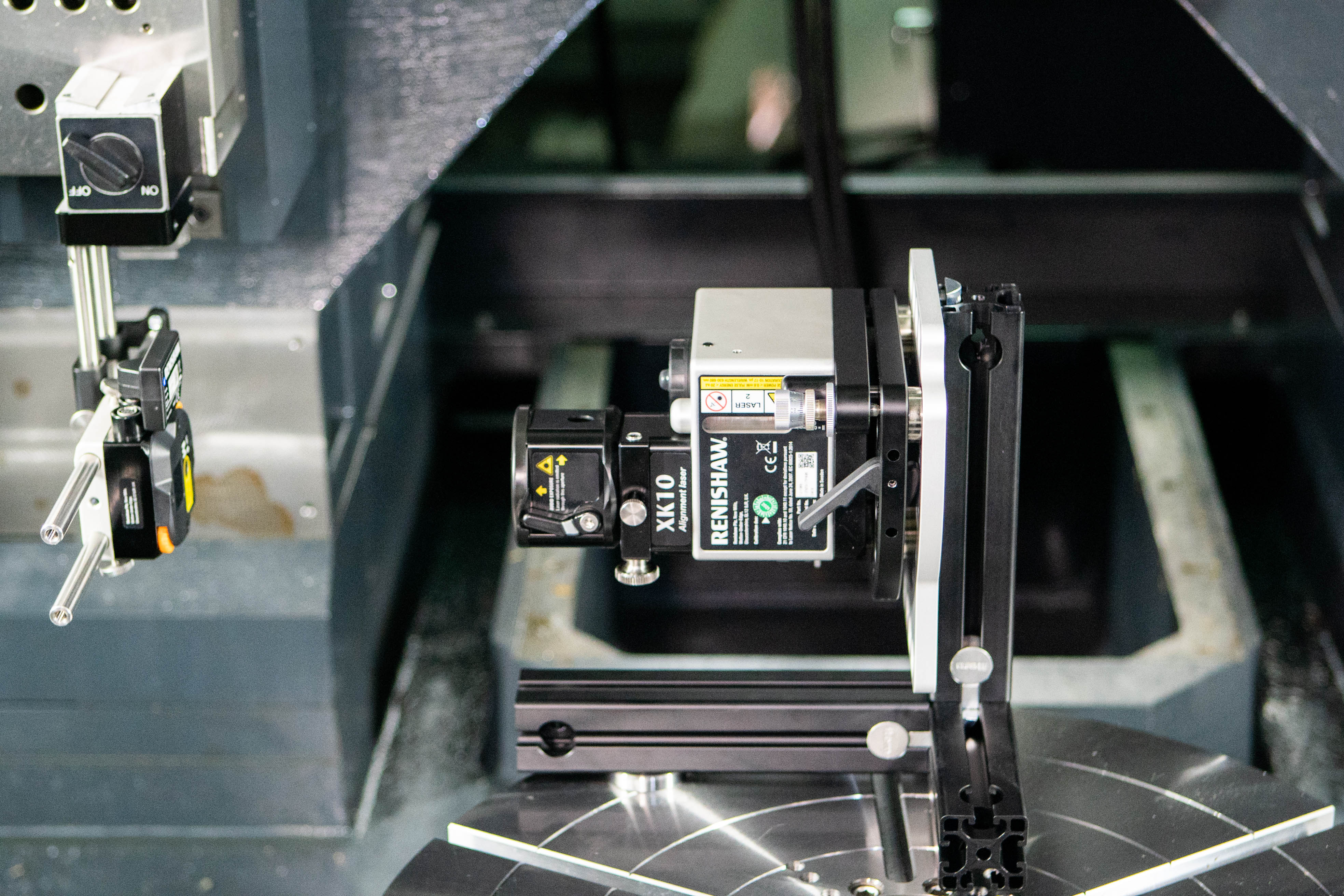

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

X axis travel:

Single movement: 2550 mm (100") inch

Dual movement: 1275 mm (50") inch

YZ axes travel: 850x600 mm (33"x24") inch

※Y axis can be increased to 1300 mm(51") (Option)

※Z axis can be increased to 1000 mm(39") (Option)

Work table: 3100x1600 mm (122"x63") inch

Max. Workpiece: 4100x2050x1250 mm (161"x81"x49") inch

Max. Workpiece weight: 22000 kg

Max. electrode weight: 500 kg

Machine net weight: 29410 kg

Oil level: 110-1000mm (4"-39") inch

Occupy size(LxWxH): 6480x6600x4600 mm (255"x260"x181") inch

Work Table to platen:

600mm Z travel machine: 1138-1738mm (45"-68")

1000mm Z travel machine: 740-1740mm (29"-69")

Filter: 4

Paper filter:8

Capacity:11300 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

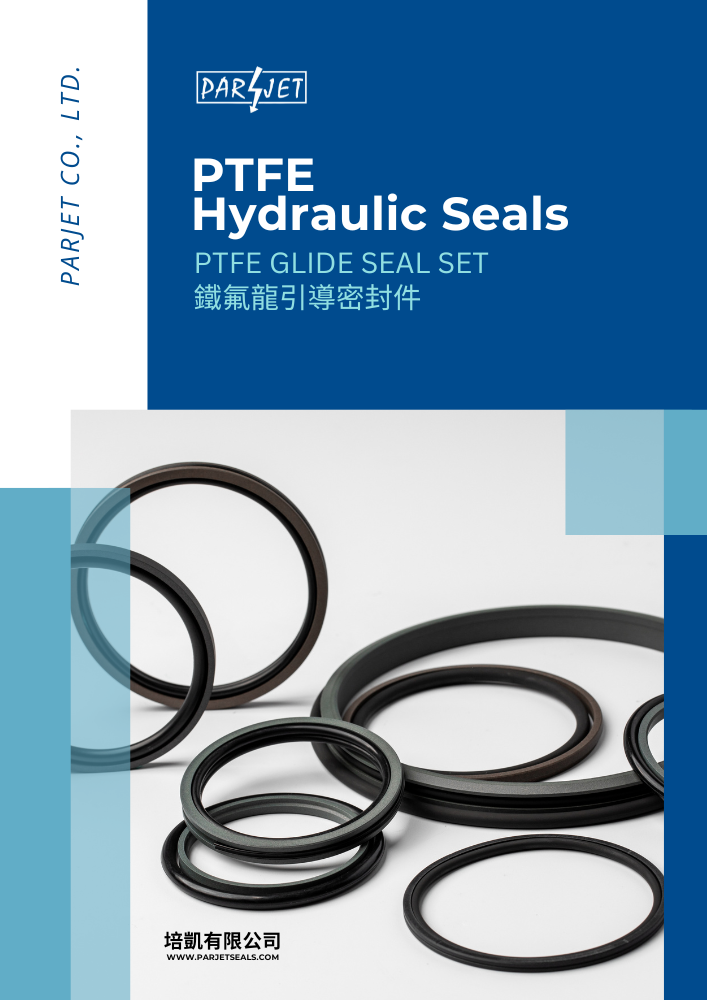

Parjet Co.,Ltd.

製品の説明 :

PTFE Glide seal sets consists of a PTFE sealing element with a rubber O-ring functioning as elastic energizer. This type of Teflon seal is mainly used to seal reciprocating rods, pistons, and plungers, commonly found in hydraulic and pneumatic applications. The required sealing effect is achieved by radial pressure, produced by the preloaded element and system pressure, on the lip against mating surface. The elastic energizer pushes the PTFE ring against the mating surface which provides the initial sealing force for the PTFE seal.

ENSINGER ASIA HOLDING PTE. LTD. TAIWAN BRANCH

製品の説明 :

Polyetheretherketone (PEEK) - TECAPEEK natural is a high performance, high temperature, semi crystalline thermoplastic manufactured by Ensinger and may use Victrex® PEEK 450G or Solvay‘s KetaSpire® KT-820 polymer. The most well known and important member of the polyaryletherketone group combines excellent wear, and very good mechanical properties, even under thermal load. Outstanding chemical resistance and a high operating temperature (up to 260°C) round out its profile, and make TECAPEEK an almost universally appropriate material for highly stressed parts.

Skeye Machinery co.,LTD

製品の説明 :

The appearance and structural dimensions of the YRTS high-speed turntable bearing (referred to as YRTS turntable bearing) series are the same as the YRT series, but the internal structure is different from the YRT series. This determines that the YRTS turntable bearing series has a higher limit speed than the YRT turntable bearing series. The friction torque is lower and more uniform than that of the YRT turntable bearing series. Therefore, this series can be selected for applications that require relatively low friction but relatively high speed, such as bearings used for shafts driven by direct drive motors.

The radial rollers use nylon retainers, so that the YRTS bearing has the characteristics of high limit speed and low and stable friction torque, so this kind of bearing is suitable for engines with torque.