展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

MATRIX PRECISION CO., LTD.

製品の説明 :

ZHS-3040 combines FANUC controller and PC, it applies linear motors and direct drive motors, developing out the six-axis-control and four-axis-move high-precision grinder. ZHS-3040 can sharpen the blade of straight and helical hobs, it can also sharpen shaper cutters and Power Skiving cutters by options. Self-developed intelligent conversation window software is easy for operation. It meets the brilliant high-precision and high-efficiency performance. One machine with multi- purpose, ZHS-3040 is your best choice.

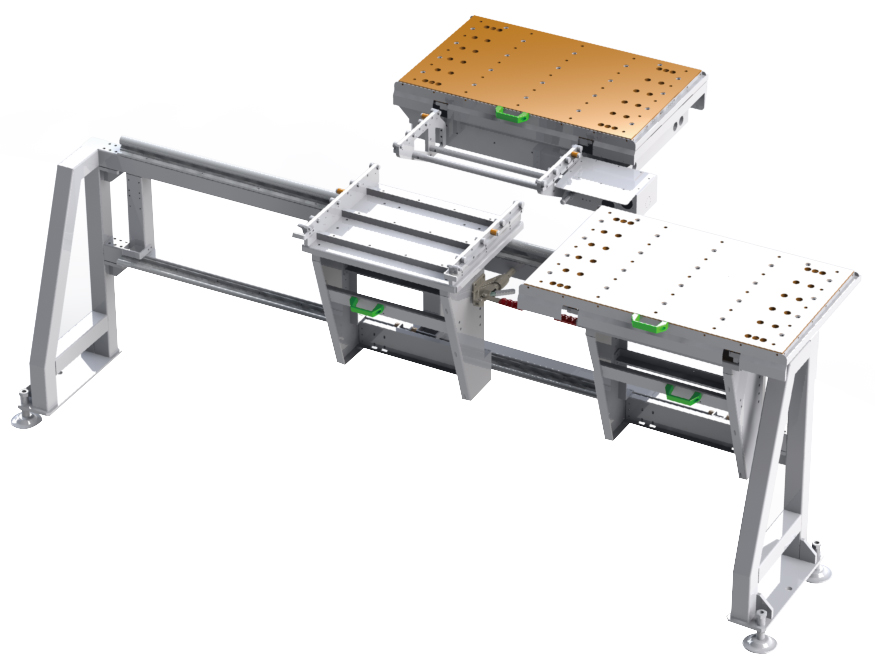

GUANDA INTERNATIONAL MACHINERY CO., LTD

製品の説明 :

Specifically designed for steel beam / structural steel processing. STD 105 equips with 3 spindles working simultaneously. Each spindle works with a BT-40 ATC, which increases the working efficiency and flexibility.

We apply MQL (minimum quantity lubrication) not only to improve the working environment but also to reduce the operation cost.

We provide various automation solutions to meet your needs.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

XYZ axes travel: 500x400x185mm (20"x16"x7") inch

U axis travel: 300mm (12") inch

Z axis single travel: 400 mm (16") inch

Work table: 800x450 mm (31"x18") inch

Max. Workpiece: 1250x650x390 mm (49"x26"x15") inch

Max. Workpiece weight: 1400 kg

Max. Electrode weight: 185 kg

Machine net weight: 2100 kg

Oil level: 110-360 mm (4"-14") inch

Packing Size(LxWxH):2340x2320x2500 mm (92"x91"x98") inch

Work Table to platen:

1. Z axis single travel: 230-630 mm (9"x25") inch

2. UZ axis: 230-715 mm (9"x28") inch

Filter: 1

Paper filter:2

Capacity:550 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.

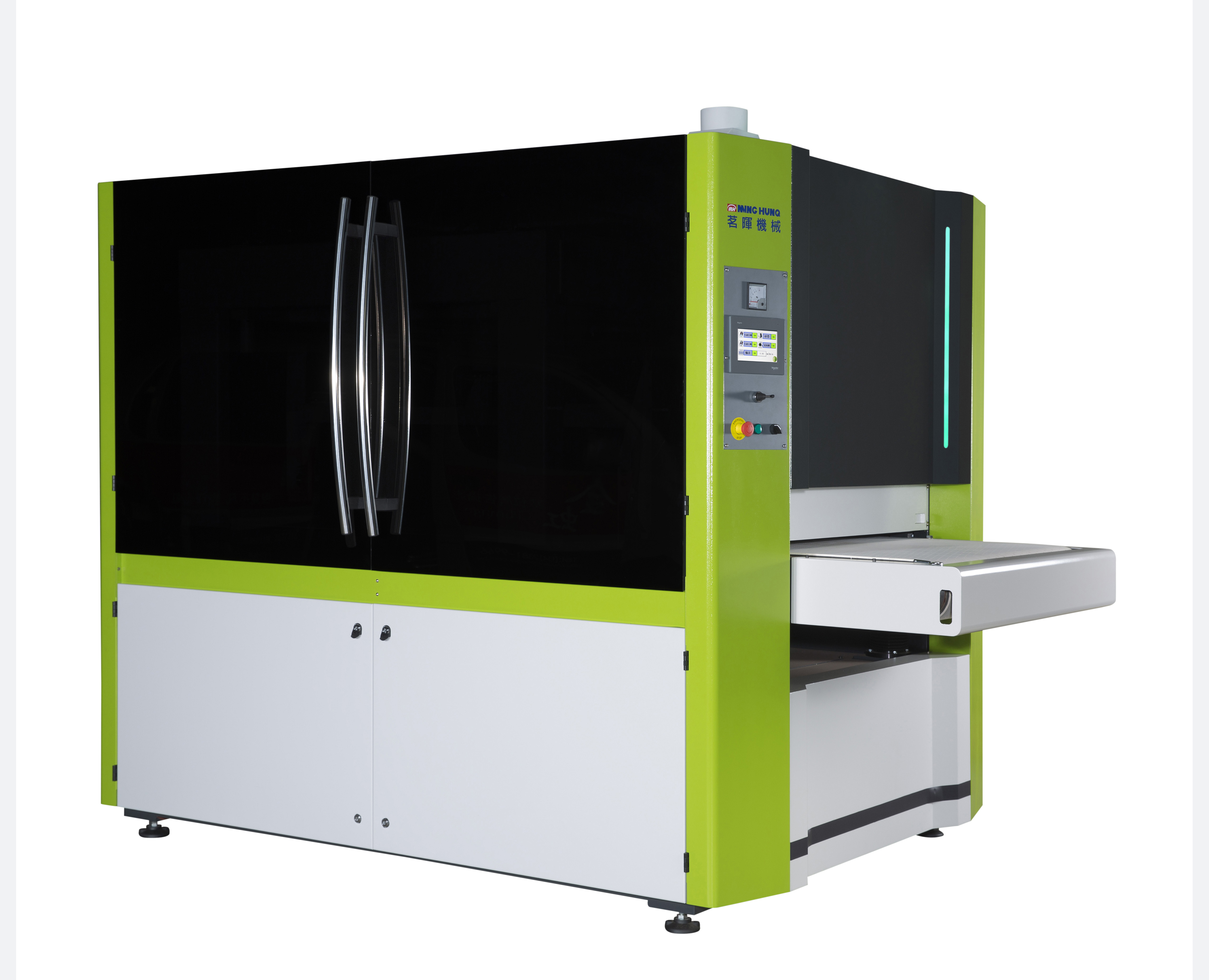

MING HUNQ MACHINERY CO., LTD.

製品の説明 :

GD-100 is a device that can serve your need for grinding and chamfering of sheet metal. Such as flame cutting, laser cutting, punching of the residue and bristles after stamping. All of the sharp angle of the edges and inner holes can easily be done on this machine.

NINE-9 CUTTING TOOLS CO., LTD.

製品の説明 :

Nine9 chamfer mill is designed for chamfering and countersinking with an indexable insert.

The insert is a specifically designed for use in high speed machining ; the multiple flutes

provide for increased feed rate, optimizing performance and reducing cutting time.

High performance chamfer tool for upgrading your machining process.

For front and back chamfering. Eliminates 2nd operation or deburring time.

● Excellent Repeatability

• Smallest Indexable counter sink, diameter ø7 mm.

• The insert is dual-relief angle, specially edge honning and optimized coated for high cutting speed.

• Optimized the number of teeth on the holder to achieve higher feed rate.

● Economical

• Each insert has 4 cutting edges.

• Long tool life.

● Applications

• For front and back chamfering.

• 90° counter sink and 45° chamfering.

• For counter sink, circular chamfering, contour chamfering and face milling.

YA LIANG INDUSTRIAL CO., LTD.

製品の説明 :

S-TYPE Special heavy duty model #122

Extremely high accuracy and precision design, suitable for CNC machining and machining center. All parts are ground, heat treated, surface treated and under specific QC condition.

H-TYPE Heavy duty model #123

Industrial design especially for milling machines and drilling machines.

All hardened parts ensure long life and safety while in operation.

VICTOR TAICHUNG MACHINERY WORKS CO., LTD.

製品の説明 :

.One piece 30˚ slant bed with large swing diameter

.10" Power chuck / 3500 rpm (A260)

. Z-axis travel 750 mm

.High thrust force by small pitch ballscrew

.High rapid feed 24 m/min (Z-axis)

.Shortened belt driven spindle

.Digital tailstock

.8” chuck for subspindle (opt.)