展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

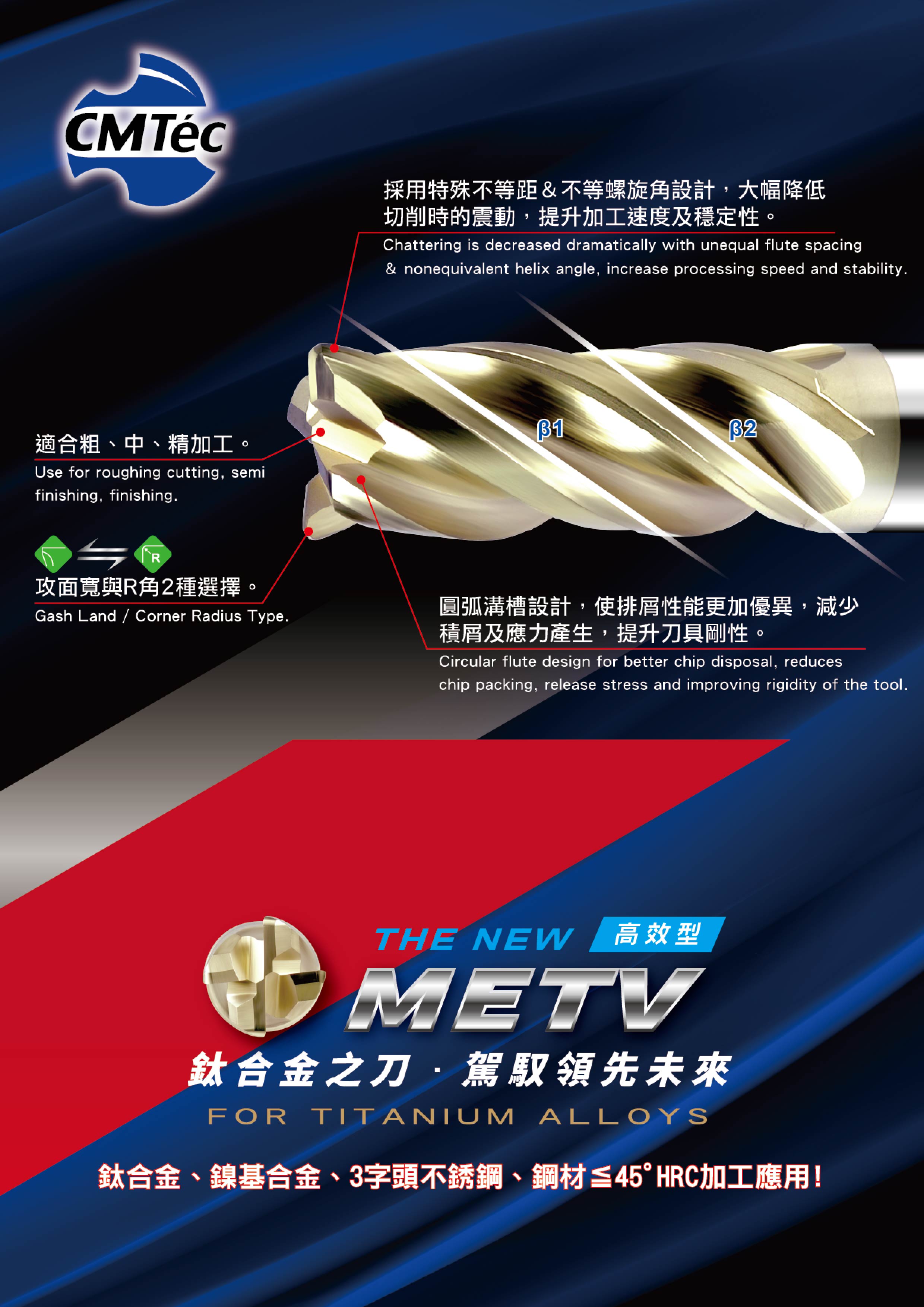

CHIN MING PRECISION TOOLS CO., LTD.

製品の説明 :

★ For titanium alloy, stainless steel and alloy steel(≦45°HRC) machining.

★ Chattering is decreased dramatically with unequal flute spacing & nonequivalent helix angle, increase processing speed and stability.

★ Circular flute design for better chip disposal, reduces chip packing, release stress and improving rigidity of the tool.

★ Use for roughing cutting, semi finishing, finishing.

RICH SOU TECHNOLOGY CO., LTD.

製品の説明 :

1. Automatic separating the parts and blasting abrasive, reduce the blasting time.

2. Equipped with air flushing dust collector, which automatically separate the dust. Correspond with the environment protection test and avoiding pollution problem.

3. Diagonal type blasting method. The operator can work and check the parts directly, which can avoid the parts missing.

4. Simulating the blasting angel and intersect blasting by CAE computer in order to achieve the surface blasting action more efficiently.

5. Suitable for bicycle and auto mobile parts, blasting efficiency increase and reduce the producing cost.

FALCON MACHINE TOOLS CO., LTD.

製品の説明 :

Chevalier has added the FRG-400/600 rotary surface grinder to our grinder series. This series features several excellent designs, ensuring a smooth and stable ribbed high-rigidity column structure, capable of handling heavy-load grinding with a fully enclosed hydrostatic rotary table.

Ample interior grinding space and a double door design contribute to ease of access for workpiece loading and unloading. The drainage system easily removes swarf for cleaning. The machine is fully enclosed with a sealed, waterproof metal guard.

This series of grinders meets the high-efficiency productivity requirements and the demand for creating smart factories in industries such as aerospace, automotive, energy, medical, and semiconductor.

iSurface control feature

Surface dressing

Surface grinding, step grinding, stair grinding

TSYR TZUN INDUSTRIAL CO., LTD.

製品の説明 :

PRODUCT FEATURES

With circuit protection of breaking for motor, once any wire of three phases power source is broken off, this unit could cut off current to motor to prevent motor from being burn out.

Drill sleeves、tapping adaptors and borer holder are with rapid adaptors, very convenient for replacement of cutters.

Tapping adaptors with torsion control, tap bits are protected from being twisted off.

The rotation speed of the MTM-930A can be changed quickly during running.

It's very convenient for the operator, and the efficiency is increased accordingly.

EUMACH CO., LTD.

製品の説明 :

HSM-5X系列是最新的機器與萬能的應用,完美回應數控五軸加工與工件的定位與刀具軸空間要求,為複雜零件的加工提供了廣闊的應用範圍。

本機採用C型架構,機床為高剛性完全支撐結構,機械經久使用,能長時間維持穩定狀態,旋轉銑頭B軸與旋轉工作臺C軸為獨立分開無重迭之兩旋轉軸,便利於工件、刀具及夾制具等設計及擺放,尤其相互干涉現象較旋轉兩軸重迭之銑頭或工作臺大幅減少。並可選用車銑主軸及高速旋轉工作台,達到車銑複合綜合加工。

HSM-5XC是大型高效切割和加工應用的最佳解決方案,無論您的重點是靈活的單元生產還是大批量精密製造,如航空工業的渦輪葉輪,葉盤等,或醫療的心臟瓣膜,人工關節或牙齒等,當然,一般加工,如模具加工或僅5面或多面加工都非常容易!

本機採用實的米漢娜鑄鐵結構,三軸為重型滾柱直線導軌進給系統,能很短時間內加速到48m/min,三軸行程1020/610/610mm,力矩電機驅動B軸連續擺動銑頭0.001角度分割,旋轉範圍-30~120゚,裝進口電機主軸26&32Kw / 124&154Nm / 18000RPM/HSK-A63設計及標準長工作台崁入φ610mm由力矩電機驅動的旋轉工作臺(C軸),最大轉速50RPM承重500KG,搭配HEIDENHAIN TNC640,15”螢幕的五軸連動控制器,HEIDENHAIN高精度三軸光學尺,刀臂式60把刀,該加工中心用於多面高性能加工和最智能的加工概念提高了生產力。

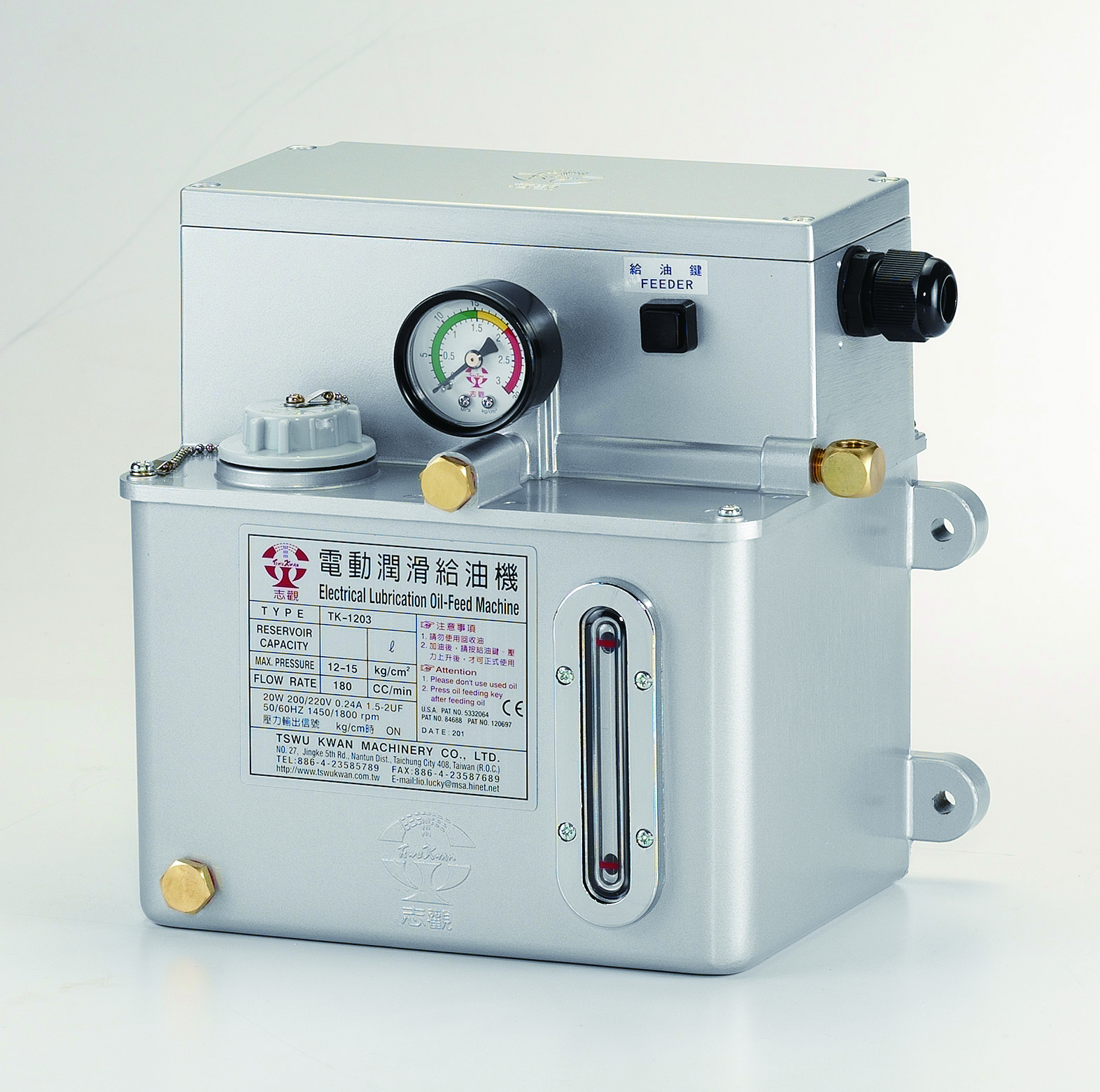

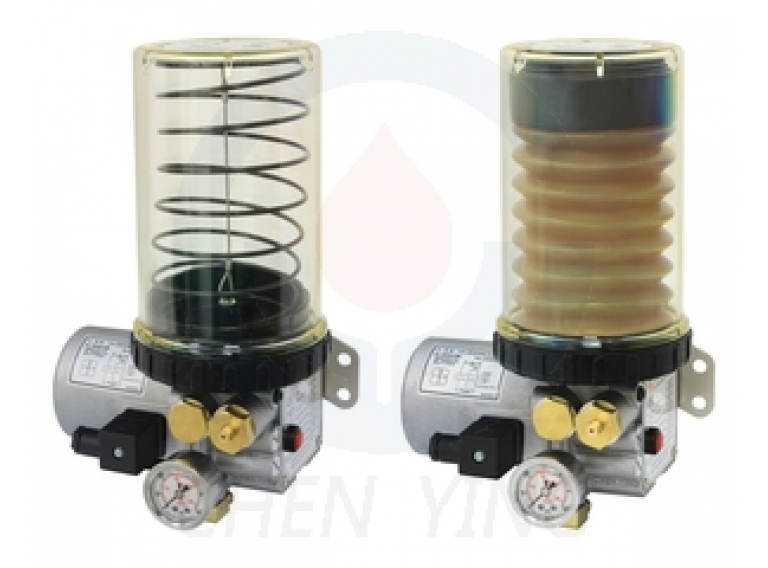

CHANGHUA CHEN YING OIL MACHINE CO., LTD.

製品の説明 :

1. KGC and KGCP types are suitable for grease NLGI grades 000, 00 and 0.

2. Recommend using a grease gun for filling with lubricant from grease inlet. It can avoid air or impurities dropping into the reservoir.

3. KGC and KGCP types are controlled by PLC (Programmable Logic Controller). It can work with CV type Progressive Feeders which can supply fixed volume of grease. CV type Progressive Feeders can assure each of lubrication point has equal amount of grease.

4. Pressure switch can be added on request for checking if the piping works normally. The standard setting is at 60 bars and the standard specification is NC (Normally Closed) contact, which means if the pressure doesn't reach the default setting, it sends continuous signals. NO (Normally Open) contact is available on request.

5. Magnet Level Switch is also an optional accessory that can be added upon request. It sends continuous signal automatically when the grease level is lower than the minimum level.

6. For the first time use, slightly press the Feed button (F button) to feed grease immediately. F button can be used as manually grease feeding for no more than 3 minutes.

7. AC110V and AC220V motors have thermal controls. When the motor temperature reaches 100℃, the sensor will be on to stop the motor continue running about 5 minutes.

8. It has a pressure gauge that the operator can check the pressure easily.

9. It can be used for the machines requiring strictly rationing grease flow. It usually works with rubber or plastic machines, press machines, machine centers, woodworking machines, etc.

G-TECH INSTRUMENTS INC.

製品の説明 :

The performance of the spindle is an important key to processing quality. When you understand the performance of the spindle, you can predict and control the quality of the processed parts. The shape accuracy, roundness, and surface roughness of the workpieces are all related to the performance of the spindle. Only when the spindle is real measuring the accuracy of the spindle at the processing speed of the machine has meaning to the control of the quality of the processed parts, so measuring and understanding the performance of the machine tool, finding the best working speed, determining the warm-up time, even confirm the accuracy of the spindle after the collision.

LION provided this SEA analysis system as early as 1993 to help spindle manufacturers, machine tool factories and processing plants to reduce workpiece defect rate and improve product quality.

★The SEA system complies with the following international standards:

✓ ANSI / ASME B5.54-2005: "Methods for Performance Evaluation of CNC Machining Centers"

✓ ISO230: Test Code for Machine Tools, 3: "Determination of Thermal Effects" 7: "Geometric Accuracy of Axes of Rotation"

✓ ANSI / ASME B5.57-1998: "Methods for Performance Evaluation of CNC Turning Centers"

✓ ANSI / ASME B89.3.4: "Axes of Rotation, Methods for Specifying and Testing"