展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

HOLD WELL INDUSTRIAL CO., LTD.

製品の説明 :

● With a U-Drive unit commanding the feed control of the tool slide and the tool placement even during rotation, it is made to o er the solution to a series of processes such as threading, conical threading, grooves, slots, curve surface machining and other complex pro

les. It makes it possible to

do turning operations on all machining centers.

● It is designed to be used on automatic tool changers to maximize the working e

ciency.

● Modular tool-holder slide with interchangeable design permits the various tool applications and machining.

● It is specially designed with two counter-weights for automatic balancing, which move opposite to the slide to e ectively eliminate oscillations.

TAILIFT CO., LTD.

製品の説明 :

全新推出ES-27全電伺服轉塔式沖床,採用全電系列AC伺服數控系統,具有高速、節能、高精度與低噪音的特色,加上過負載自動保護設計,是沖壓高精密薄鈑件的利器。它的集成式組裝方式,有效減少地面安裝空間。因具有沖孔、成型、滾切與攻牙等多功性能,可減少無效率工時的等待,大大提升加工效率。

另外節能方面,平均耗電顯著降低,無液壓油的消耗,是環性保護需求的綠色產品,這也是機身基座採O型龍門式架構設計,經世界級頂尖實驗室使用結構有限元素分析後,完成機身機座各部結構之靜性結構分析、剛性結構分析、暫態分析等應力結構性資料。

在構造機身基座之材料上,選用高強度鋼材焊接,引進尖端熱處理技術,消除焊接產生的熱內應力,使機身金屬結構完成統一機身機座,在精加工前更再經過高張力測試、正常化處理與震

動應力消除等三道防線嚴格把關,使機身組裝精度維持一致性。

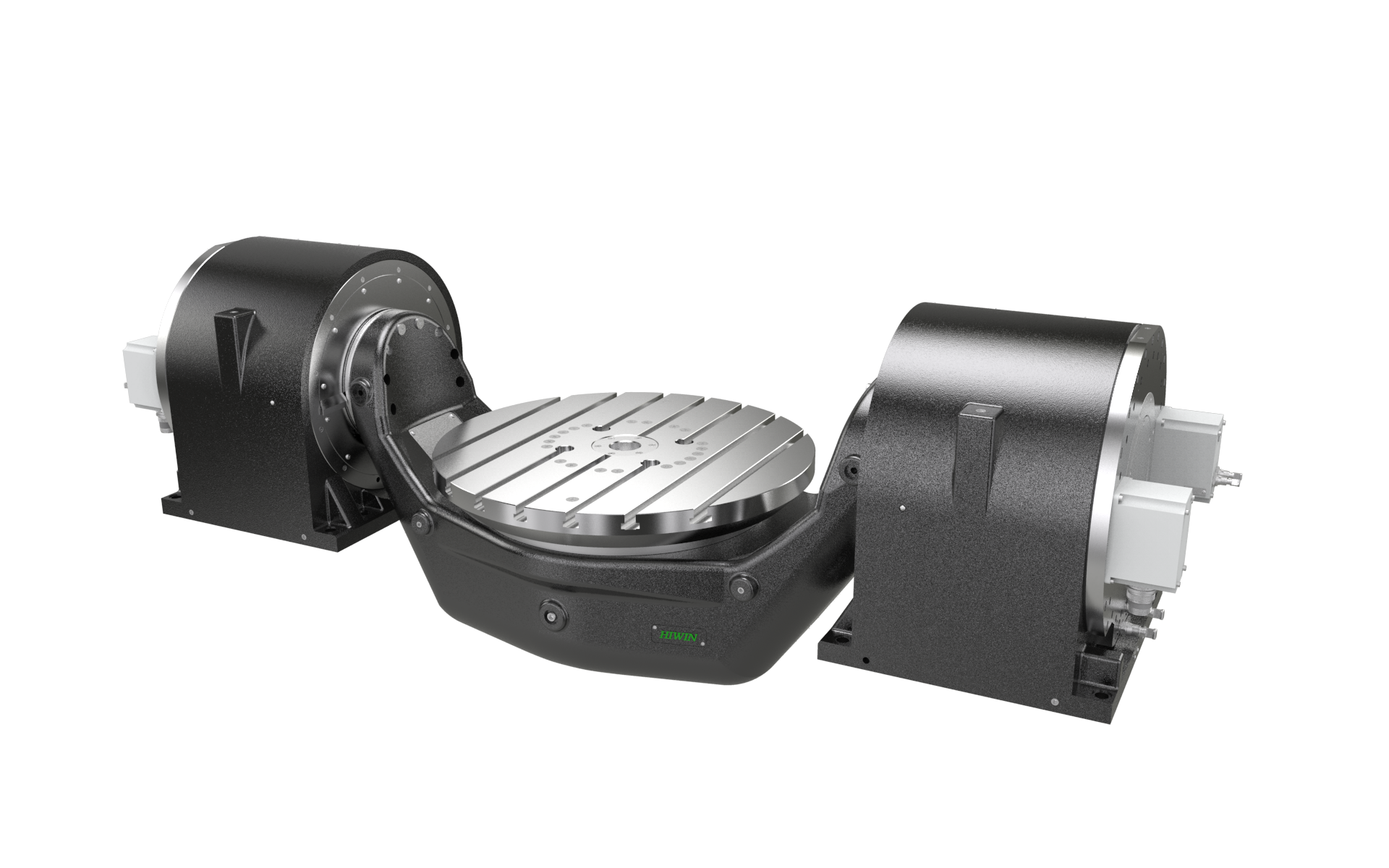

HIWIN TECHNOLOGIES CORPORATION

製品の説明 :

HIWIN Torque Motor Rotary table equips with HIWIN’s water cooled direct drive motor. With features of high torque, high precision and zero backlash including crossed roller bearings and pneumatic braking system, which plays an important role in the multi-axis machines. These rotary tables can increase the competitiveness of the machines with high speed, high performance, high precision and one time machining program reducing the errors during disassembly and clamping of components between multiple machines to complete the machining task, achieve the ability for complicate curve machining in one setup.

① The underwater rotary table (RCV-E series), lightweight insulation, up to IP 68 -rated waterproof and dustproof, suitable for discharge rotary cutting and grinding processing applications.

② Double axis rotary table (RAB/RAS Series)

Key component for high end multi axis machining center.

③ Single axis rotary table (RCV/RCH Series)

Widely used in turn-mill machining centers with speed up to 2,000 RPM.

COMETECH TESTING MACHINES CO., LTD.

製品の説明 :

If you are looking for a low-cost but with great function performance motor driver, then the C2A series will be a great bargain. This series is suitable for motors below 150W, and the small size occupies no space. Besides adjusting the motor speed, users can set up detailed motor-related data settings with our C2 series driver. Its multifunctional integrated design is the main feature and advantage for saving costs and reducing external components.

Users can connect directly to the dedicated software for easy parameter tuning and configuration with the built-in Wi-Fi module. An over-the-air firmware update without assembling the driver from devices can improve maintenance efficiency and convenience.

Moreover, the driver features a modular expansion design that allows flexible extensions of communication formats, wireless screen modules, and more to meet various user needs.

※Specification

-Rated Voltage: DC 12~48V

-Rated Output: 150W

-Rated Current: 7.5A

-Applicable Motor: BDC, BLDC

-Motor Feedback: Hall Sensor, Sensorless; Encoder input signal is available

-Communication Interface: Built-in Wi-Fi module and RS-485

-Speed Control: Analog input, Command sources

-Display: 2.8" wireless color touch screen for options

-Software: Equipped with dedicated motor monitoring software which is available to connect with mobile devices (smart phone, pad, notebook, etc.) through Wi-Fi.

※Features

-Compact size

-Integrate multiple functions to reduce the external components' cost

-Monitor the motor's status such as voltage, current, speed, etc. through dedicated software

-Data setting and devices' status monitoring by dedicated software through Wi-Fi connection

-Support different motor control modes (revolutions, distance, operation speed, etc.) and multi-step programmable settings

-Modbus-compatible driver for various host controllers.

-Over-the-air firmware update

-Multiple I/O (open collector) for flexible expansion of different applications