展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

MATRIX PRECISION CO., LTD.

製品の説明 :

GVP-8040 applies the FANUC controller and high speed grinding spindle, through the Matrix developed intelligent conversations window software, it can flexibly output the required tooth profile and grinding parameters. The machining workpieces include involute gears, large-module hobs and cycloidal gears, the high-efficiency and high precision expressed from the products are equivalent to worldwide top brand’s ones. GVP-8040 is your best choice.

SHE HONG INDUSTRIAL CO., LTD.

製品の説明 :

+ X & Y axes linear motor dirven

+ Double ballscrew drive design for Z axes

+ Four linear guideways on Z axes

+ Thermal growth control on Z axes

+ Roller type linear guideways on 3 axes

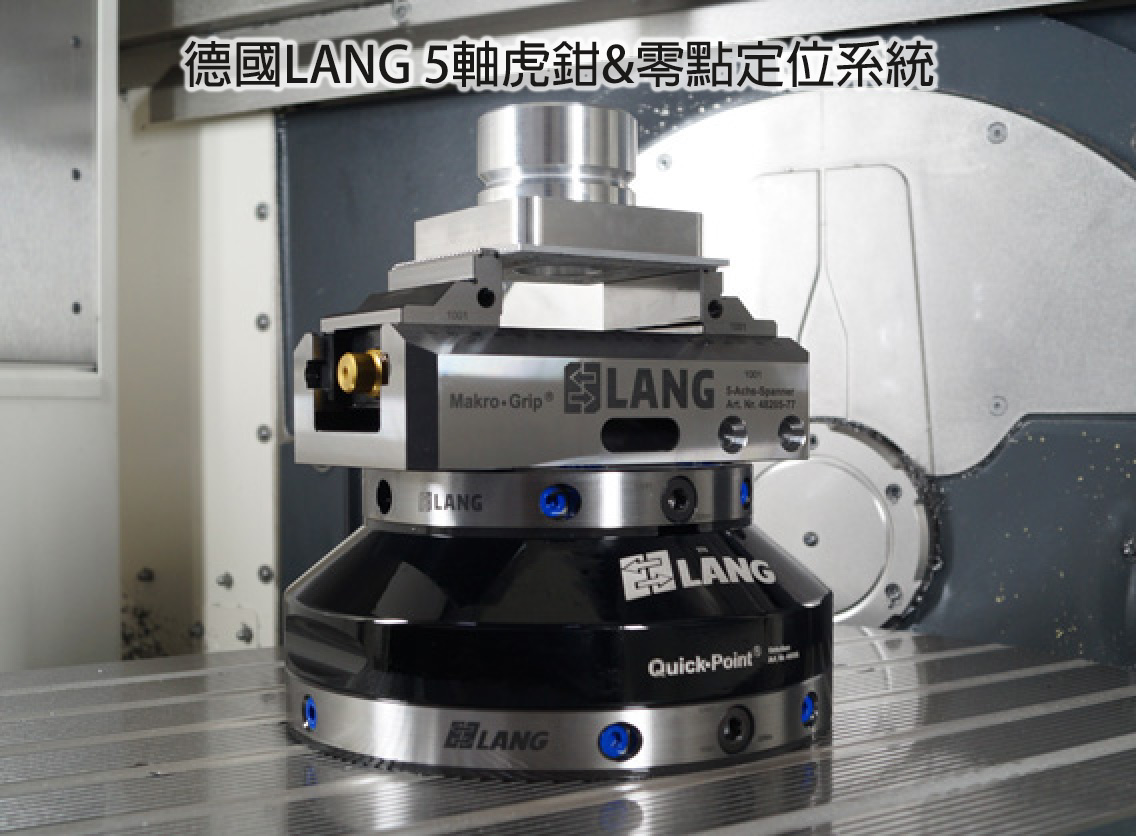

LIN PONG TRADING CO., LTD.

製品の説明 :

零點定位系統 簡單•可靠•高精度。

配合各種加工機械的需求提供多樣零點定位治具方便選擇。

適用於 "5軸、立式、臥式".... 等CNC加工中心機。

HONG JI PRECISION MACHINERY LTD.

製品の説明 :

This machine is applied to deep hole reaming to reach high accuracy in hole roundness. It is suitable for reaming center holes of gun barrels and long shafts.

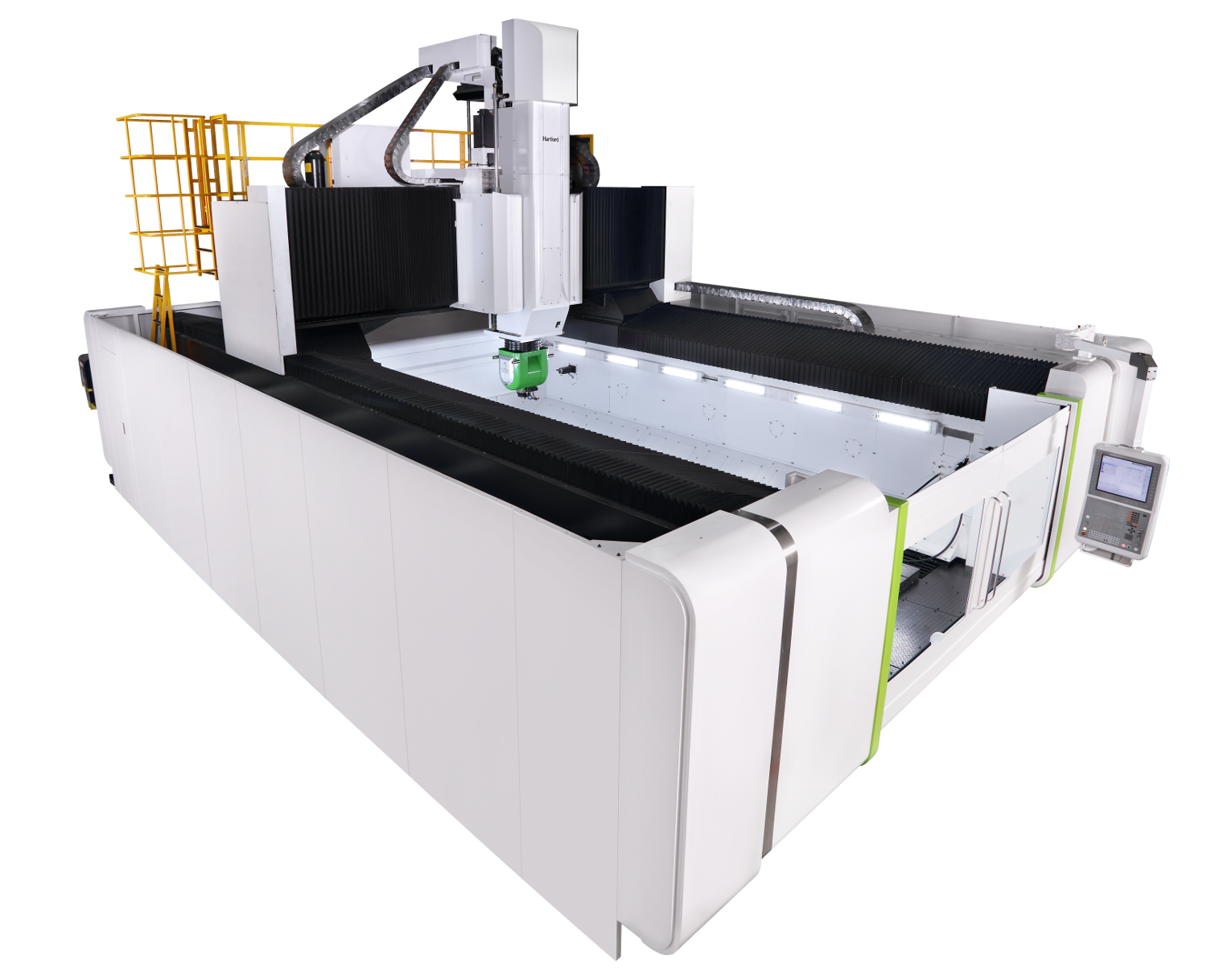

OCEAN TECHNOLOGIES CO., LTD.

製品の説明 :

(1) CNC Drilling EDM — RIVER 600 + Auto work piece changer

with robotic arm

All-intelligent machining equipment with Robot

- Automatic tool changer

- Automatic guide changer

- Automatic work-piece changer

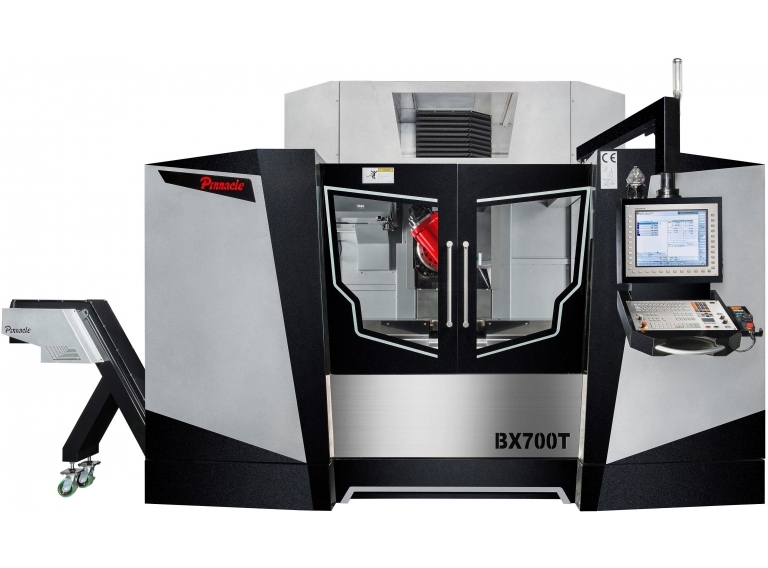

PINNACLE MACHINE TOOL CO., LTD.

製品の説明 :

2台立式 + 車床? <br />

立式+4軸轉台 + 車床?<br />

5軸機 + 車床?<br />

還在為複雜的工件煩惱買什麼機台嗎? <br />

BX700T絕對是最佳首選! Milling and Turning 銑車複合的五軸加工中心,B軸擺頭+/-120度,搭配內藏式15000轉主軸,內坎式C軸直徑630mm工作台,C軸轉速有800轉及1200轉作選擇。。專利設計,完美結合:最大的加工空間、最小的干涉、高精度及高效率的五軸銑車複合機。一台抵三台,投資成本相對少,佔地空間小。<br />

BEST DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

Compared to resin bond and metal bond wheels, Electroplated Grinding Tools are noted for relatively large grit protrusion and higher abrasive concentration. This results in very free cutting properties and in high stock removal capacity. Besides, these tools are noted for:

1. Allow special shapes and profile tools to be made at short notice.

2. Cause very little change on wheel shape after used, suitable for precision grinding.

Application and Processing Material for Electroplated Grinding Tools :

1. Internal grinding: Suitable for the internal grinding of carbide and High Speed Steel. The smallest diameter of our electroplating area is 0.3mm so it could be used in drilling for fined ceramics.

2. Jig grinding: Mostly used in fined ceramics processing and precision grinding for quartz. Customized items are also provided to cater your needs. Common grit size is #80~#325, good for rough and fine processing.

3. Touchscreen Processing: Drilling and chamfering for the glass panel of the smart phone and tablet computer. In order to improve work efficiency, we could also combine different grit sizes in the same diamond mounted point.

4. Grinding for Cutting tools: Normal end-mill grinder and drill grinder go with electroplated wheel. Carbide can be ground by diamond wheel and High Speed Steel could be ground by CBN wheel. Bowl-shape wheel with standard specification is also provided, suitable for the grinding of turning tools.

5. Precision grinding: Electroplating can produce wheel of different shapes without deforming it. Therefore, it is suitable for precision grinding or trimming aluminum oxide wheel.

6. Gem grinding: shape grinding for gem, semi-precious stones, shell and jade.

JIUH-YEH PRECISION MACHINERY CO., LTD.

製品の説明 :

1.以「電子式MPG」自動化技術、減少誤動作、節省人力

2.MPG微量進給,高精密、高效率之滾珠螺桿,及伺服馬達

3.人機介面之設計

4.立臥兩用雙主軸一體式結構設計

5.主軸溫升防護系統、潤滑油冷卻循環裝置加上非接觸式與迷宮式路徑結構設計

GTW Taiwan Ltd.

製品の説明 :

We develop excellent electric motors that meet every test requirement in the field of e-mobility. We were able to develop a new type of motor family-the RigBes. New bearing concepts and advanced cooling strategies enable temperatures in the motor elements to be kept below 120°C under all operating conditions. Bearing temperatures never exceed the 50°C mark, even at 28,000min-1.