展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

HAI JU TRADING CO., LTD.

製品の説明 :

螺紋護套, 是一種高強度的緊固件, 能在低強度的材料中提供高強度的緊固功能,螺紋護套已經在市場上發行約超過60年, 這些不銹鋼螺紋護套是以菱形輪廓的鋼線製成彈性螺旋, 並且經過質量驗證。護套安裝後,在導舌預定斷裂點折斷導舌,以使螺紋護套通孔.<br />

<br />

<br />

<br />

由於不斷的改良與優化,HELICOIL®Plus 螺紋護套 現在更容易安裝。<br />

<br />

與HELICOIL®經典螺紋護套做比較, HELICOIL®Plus的線圈有特殊的起始, HELICOIL®Plus同樣是以菱形輪廓的鋼線製成的彈性螺旋, 於由線圈有特殊的起始, 安裝時可以像螺絲一樣被定位並擰入, 搭配現有的同一公稱系列工具組裝,與HELICOIL®經典螺紋護套的安裝做比較, 能縮短將近20%的安裝時間. <br />

<br />

<br />

<br />

HELICOIL®Plus 提供高強力, 能從側面到側面, 將力傳遞到螺紋。<br />

<br />

這種高度可靠性的系統已被德國和國際工業產權提交。 HELICOIL®Plus根據一致性的材料和質量規範生產螺紋護套, 並滿足國家標準化以及航空和軍用標準的要求。 除此之外, 許多領先的大型用戶亦以HELICOIL®螺紋護套為基礎做為製造標準。<br />

<br />

<br />

<br />

<br />

<br />

Rm = tensile strength 1,400 N/mm2 min.<br />

HV = vickers hardness 425 HV 0.2 min.<br />

RZ = roughness depth approx. 2.5 μm<br />

μG = reduced thread friction, results in increased preload-force FV<br />

τt = reduction in torsion stress in the screw shank<br />

===========================================================<br />

<br />

HELICOIL®無尾螺紋護套<br />

<br />

1.無折斷,無斷裂<br />

-無風險的留在組件<br />

-減少安裝時間<br />

-減少測試時間<br />

<br />

2.降低刀具磨損<br />

-工具刀片的磨損最小<br />

-易於維護<br />

<br />

3.提高品質<br />

-簡單化的品量保證<br />

-高強度的配合螺紋盲孔深度或預裝配組件<br />

-符合NA0276標準

RUN ACE CO., LTD.

製品の説明 :

The Bonfiglioli reducer combines many advantages such as extraordinary quality and extremely high cost efficiency. The product has a variety of mounting shaft configurations and motor interface options, and all options are standard, providing users with absolute flexibility. With many patented manufacturing technologies, Bonfiglioli products have ultra-long service life and reliability, and this product is the perfect partner for various motors.

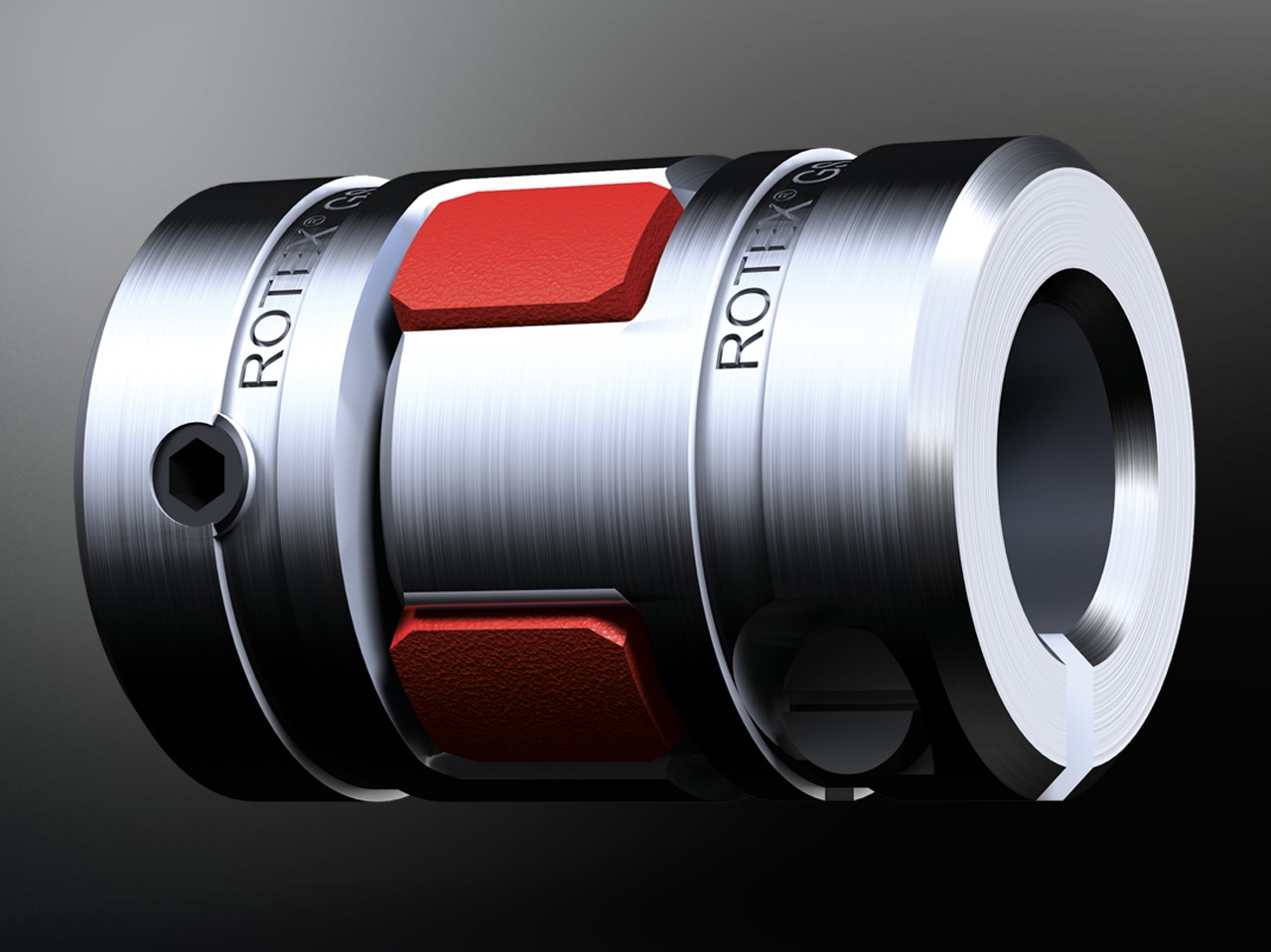

KTR TAIWAN LTD.

製品の説明 :

ROTEX® GS is a three-part coupling, backlash-free under pre-stress. The different hub designs and the different Shore hardnesses offer the optimal coupling for each application in automation engineering. In spite of its vibration-damping characteristics it is torsionally stiff so that it is not necessary to make any concessions to accuracy even with highly dynamic servo drives. The ROTEX GS works with the modular system; a high variety of different hub designs is available which can be combined within one coupling size.

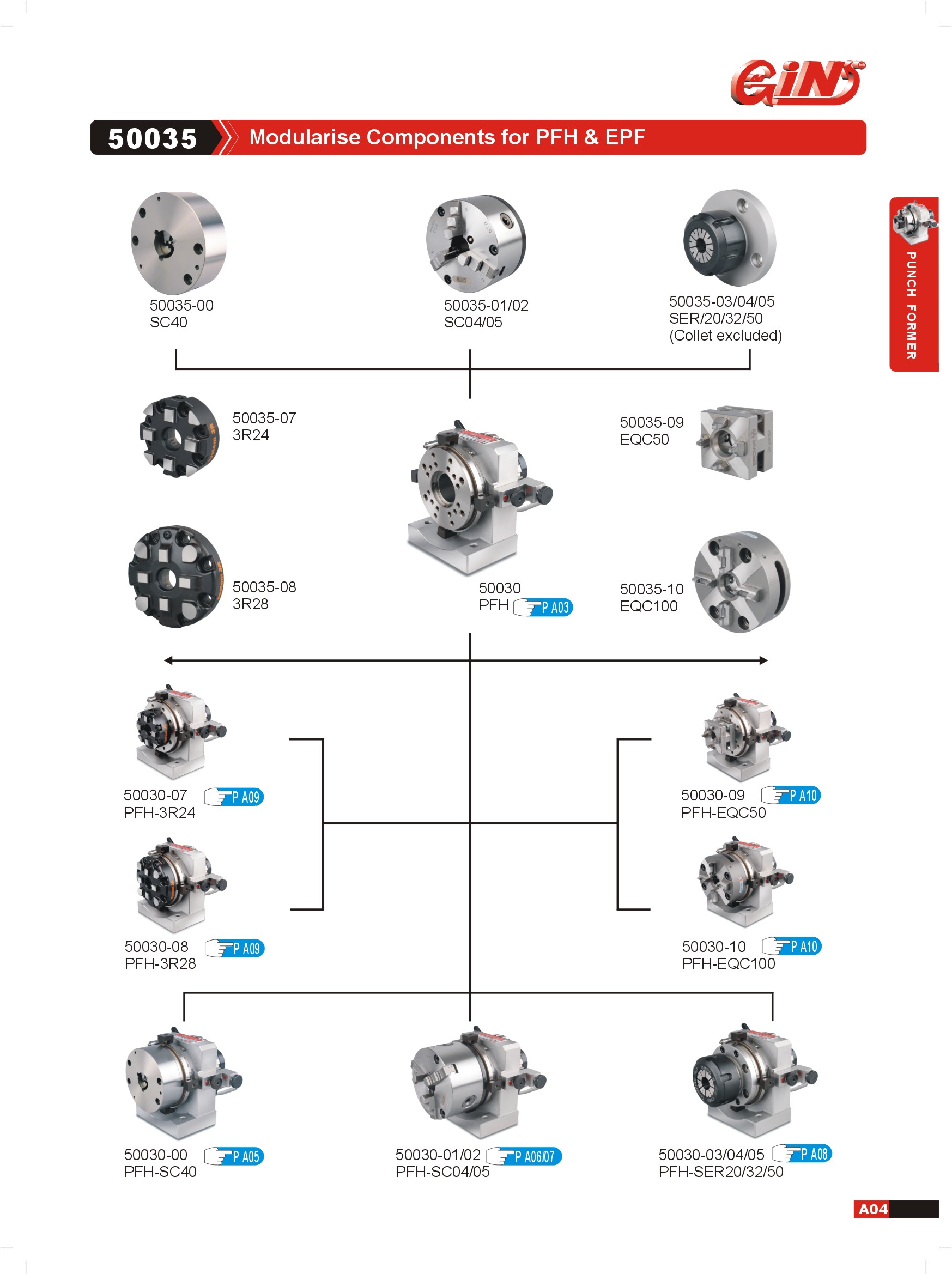

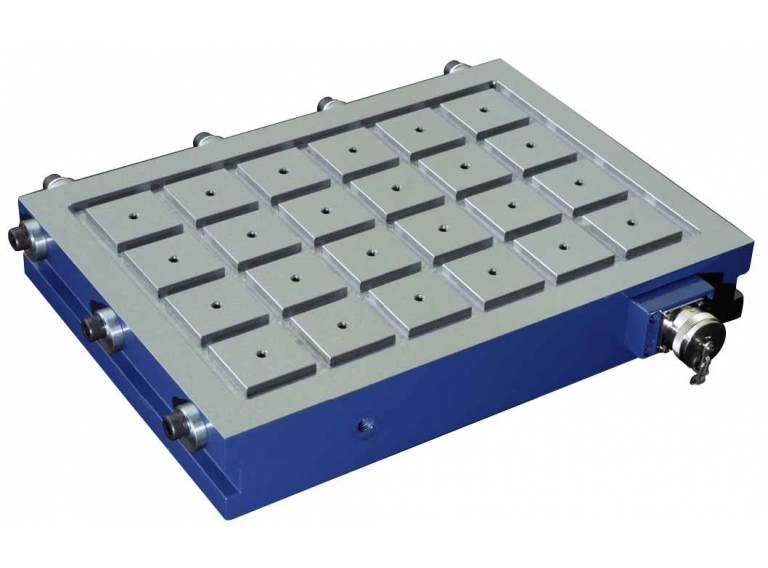

TAI CHONG CO., LTD.

製品の説明 :

用途: CNC切削中心機,銑床,龍門銑床,電腦銑床等切削作業。<br />

特性:<br />

本體與面板一體成型加工完成。<br />

以電控操作,快速充脫磁場變換。<br />

以永久磁鐵吸著工件,沒有停電的危險性。<br />

吸磁作業面,螺栓孔可應用於模具及固定方式的變化。<br />

可配合彈性導磁塊,針對變形平面,作平面加工,大量節省調整時間,提高工作效率。<br />

結構剛性佳,配合精度穩定,適合高精度加工作業。<br />

與強力型電磁鐵比較,大幅度節省電力消耗。<br />

防水效果最確實,保證不漏水,不漏電。<br />

平均吸磁力18kgf/cm2以上。

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

XYZ axes travel: 500x400x185mm (20"x16"x7") inch

U axis travel: 300mm (12") inch

Z axis single travel: 400 mm (16") inch

Work table: 800x450 mm (31"x18") inch

Max. Workpiece: 1250x650x390 mm (49"x26"x15") inch

Max. Workpiece weight: 1400 kg

Max. Electrode weight: 185 kg

Machine net weight: 2100 kg

Oil level: 110-360 mm (4"-14") inch

Packing Size(LxWxH):2340x2320x2500 mm (92"x91"x98") inch

Work Table to platen:

1. Z axis single travel: 230-630 mm (9"x25") inch

2. UZ axis: 230-715 mm (9"x28") inch

Filter: 1

Paper filter:2

Capacity:550 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.