展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

SUN FIRM MACHINERY IND. CO., LTD.

製品の説明 :

The latest Sun Firm CST-46160 is a horizontal CNC precision lathe offering high flexibility and processing efficiency. Our specially designed spindle accommodates up to two sets of mandrels at the front and back, which is perfect for processing long tubes or bars. The turret is designed to fit the rigid platform-type rail structure, providing the best balance between high cutting resistance and processing efficiency. The design of the body structure is complete and the interface is taken into account in advance. It can support the robot arm, the automatic power system as well as the power turret and lead to a more efficient treatment, bringing us win-win benefits.

XONYON CORPORATION LIMITED

製品の説明 :

HYDROKOMP high-pressure coupling joint, can be applied to high-pressure 500bar, 4.5mm short stroke , and can customize 2.5mm ultra-short stroke.

CHANGHUA CHEN YING OIL MACHINE CO., LTD.

製品の説明 :

1. CEN03 type is without timer (also could be controlled by Programmable Logic Controller) and has to work with volume distributors. With CAB or CBB type volume distributor, oil will feed during operation time. With CDB or T type volume distributor, oil will feed during interval time.

2. The discharge volume is fixed. The lubrication points of volume distributor supply a fixed flow of oil.

3. It has a spark-eliminator inside to prevent the sparks producing when the electric current is running. The spark-eliminator can avoid PLC (Programmable Logic Controller) being interfered.

4. CEN03 type has a pressure switch device and been set up as 8kg/cm2, which assures the oil volume of lubrication point and check if the piping works normally. The standard specification is NC (Normal Close) contact, which means if the pressure is abnormal, it will have signal. NO (Normal Open) contact is available on request.

5. It has a float switch that can detect the oil volume. When oil is lower than the minimum level, the float switch will automatically send a continuous signal.

6. It has a pressure gauge where an operator can check the pressure easily.

7. Do not press the force feed-oil (F button) more than three minutes in order to avoid overloading. When the temperature reaches 100℃, the sensor will be on to stop the motor continuing running about 5 minutes.

8. It can be used for the machines requiring strictly rationing oil flow. It is usually used for such as processing machines or projecting machines.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

XYZ axes travel: 600x400x400mm (23.62"x15.74"x15.74")

W axis travel: 450mm (17.71")

Work table: 650x450mm(25.59"x17.71")

Max. Workpiece: 900x500x300mm(35.43"x19.68"x11.81")

Max. Workpiece weight: 700kg

Distance from table to guide plate:25~425mm(0.98"x16.73")

Machine dimensions: 1580x1250x2740(62.2"x49.21"x107.87")

Machine net weight: 1200kg

Electrode diameter: 0.2~3.0mm

Dielectric fluid: pure water ( dielectric oil for 0.2mm or below)

Filtration: Paper filter

Controlling axes XYZW

Monitor: 15” LCD screen

Input/output unit: LAN/USB

Min. Setting Unit: 0.001mm

Min. Moving Unit: 0.001mm

Graphical display: 2D

Machine Features

1. This system utilizes Windows CE controller.

2. Able to store data through USB and internet.

3. Dialogue window, along with picture description functions.

4. Touchscreen type interface.

5. Special repaired frames to quicken the maintenance speed.

6. Close-Loop design of digital feedback on three axis of the machine, significantly increases positioning accuracy.

7. Possessing good and simple operation interfaces

Common function keys are located on the operation panel for direct use, hot key function on screen for quick access.

8. ATC (automatic tool changer) and AGC(automatic guide chnger) can be installed

9. Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to search.

10. Automatic origin search and multi-point coordinate memory capability.

11. Chinese/English versions, Metric/British system switch and quick up, quick down, and slow up and slow down capabilities, resolution can reach 1um.

12. All alarms describe the source, data and exact time of problem occurrence.

13. Able to proceed standard GM code and extra GM code

14. Able to proceed DXF file transfer to position coordinate function

15. AB axis rotate table can be installed

16. Position simulation and work route can be displayed

17. During discharge change new electrode can automatically compensate depth

18. Backlash point automatic compensate function

19. Able to do single hole drilling, multiple hole drilling and multi thickness drilling

20. Blindhole drilling function, any depth can be set

21. Initial current can set to reduced value, which can prevent workjob surface damage

22. Initial polarity reverse function, can prevent uneven electrode caused efficiency decrease

23. Six axis linear interoperate accelerate speed movement

24. Input, output, various of machine status real time display system

25. Discharge program and parameter conversion function

Accessories

《 Standard Accessories for High-speed Drilling CNC EDM 》

Tool Box*1

Brass Electrode 1.0mm*10

Electrode Guide 1.0mm*1

Standard Chuck*1

Foot Pads*1 set

Filter*1

Rubber Seal*10

Halogen Work Lamp*1

Flushing Unit*1 set

《 Optional Accessories for High-speed Drilling CNC EDM 》

ATC

Electrode Guide(Other diameters)

Brass Electrode(Other diameters)

ER Type Chuck for electrodes up to 6mm

Submerged Work Tank

75Amp Power upgrade

Filtration System with Resin Bottle

A,B Axes

Automatic guide changer 3/6

Fey Che Trading Co., LTD.

製品の説明 :

*刃部採用特殊塗層處理,適用一般鋼材、塑膠、鋁及不銹鋼。

*柄部採用端銑刀柄徑,剛性強,加工效率更好。

*刃徑1mm以上有橫刃與齒隙,可提升定心效果及減少切削阻力。

YOUN JIN ENTERPRISE CO., LTD.

製品の説明 :

Automatic point marker is the best tool final the central poinet before punching.

It's operated to aim at the central line and be pressed downward ; the central point will appear.

The size of the point can be adjusted by the pressure lid , no need to use hammer.

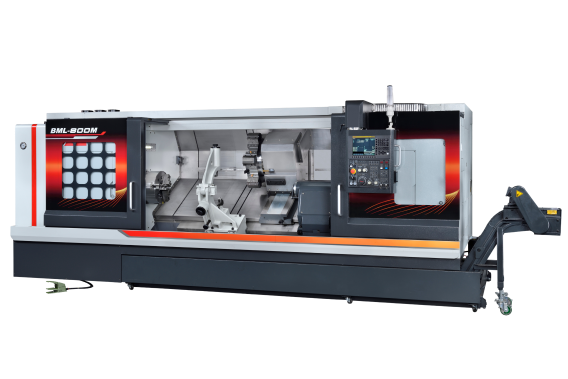

YIDA PRECISION MACHINERY CO., LTD.

製品の説明 :

The (B)ML-800 series is a highly customizable turning center with various options for spindle, gearbox, base, tailstock, turret and multiple selectable feed speeds. It can efficiently handle the most demanding machining requirements.

1. The modular structure design of the base has high strength and rigidity. It is molded as a single unit, effectively absorbing the vibrations generated by the machining and providing the stability and precision required for heavy cutting operations, without any distortion or deformation.

2. The optimal modular design spindle features high speed and power, and can be paired with a high-torque output gearbox design, offering a variety of processing options to meet different machining needs.

3. The robust toll turret design allows for quick and reliable tool changes, ensuring high efficiency and precision. It caters to the characteristics of various cutting processes, effectively enhancing machining capabilities.

3. The high-strength design of the transmission structure ensures precise positioning and greatly enhances machining efficiency and stability.

4. Ergonomically designed interface makes operation easy and maintenance convenient. Sheet metal design incorporates comprehensive safety considerations.

EXCELLENT GEAR TECHNOLOGY CO.,LTD

製品の説明 :

Gear manufacturing: automobile and motorcycle components, machine tools, reducers, industrial gears

GT MARKETING Co., LTD.

製品の説明 :

Cloud Computing Mobile App

The popularization of smartphones, tablets, and 4G networks have changed the modern marketing models; to help customers take the lead in grasping market opportunities, we combine cloud computing services and tailor-made mobile native apps for iOS/Android to help companies to create all-round competition advantages, looking forward to establishing a long-term partnership with customers for win-win and common prosperity.

Enterprise Self-Platform

Plan the backend management system for customers according to their needs, and assist customers in solving the pain points in the operation process and content management, such as membership management, production line management, machine registration, web content management, App content management, etc., in an all-in-one integrated backend management system, looking forward to providing customers with the best information integration platform.

Cloud Computing Hosting Service

GTMC cooperates with leading cloud computing brands: Microsoft Azure, Amazon Web Services (AWS), Google Cloud Platform (GCP), Alibaba Cloud and Chunghwa Telecom IDC. We have cloud computing services and the latest technology to provide customers with the best solutions.

Exhibition Service

Assist the organizer to manage manufacturer and visitor information, provide visitors to accurately find exhibitors and products, increase the popularities of exhibits online with the most intuitive search method and use the APP functions for visitor registrations, event calendar and booth map to help for the exhibition hosting.

3D Display Solution

Integrate 3D technology on the company marketing website and present perfect product design drawings through excellent 3D designers to help customers understand the products. In addition, it supports real-time change of product appearance according to selection requirements, completes quotations and sets product specifications, and assists to increase product sales and accelerate production.

BORE AUTOMATION TECH. CO., LTD.

製品の説明 :

40 PIN Interface Module, equipped with WAGO PUSH-IN Type PCB terminal block, indication LED's for output status , with high quality IDC/MIL connector, fully compatible with variety PLC/CNC controller, Ultra-narrow, space-saving

HUI BAO ENTERPRISE CO.,LTD

製品の説明 :

FEATURES:

Able to clamp the workpiece from both inside and outside, apply for embedded sensor, two directions inlet

APPLICATION:

CNC loading and unloading the workpiece, jigs and fixture

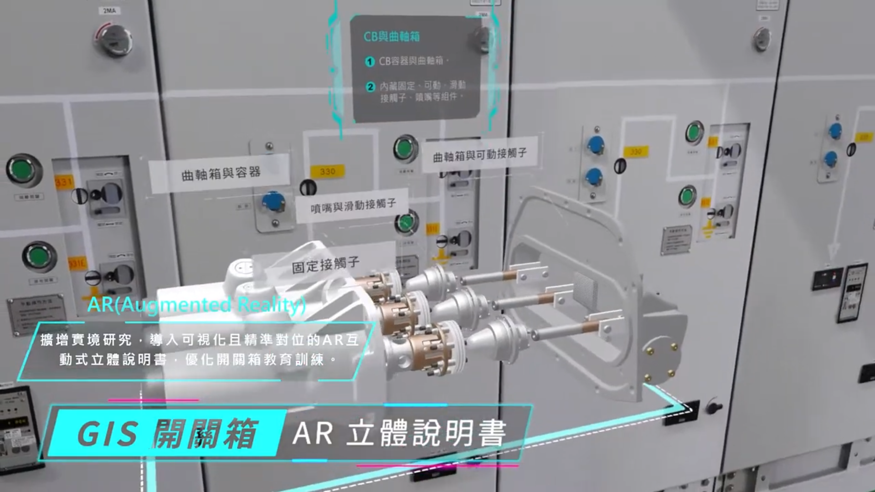

Administration for Digital Industries, moda

製品の説明 :

The Industrial XR SOP Solution""utilizes AR/VR/MR cross-platform integration technology to ensure seamless operation across various devices such as smartphones and head-mounted displays. It is specifically designed for the industrial sector as an XR intelligent carbon reduction integration platform service.

It's key features include support for ""cross-temporal"" information transmission and real-time monitoring, enabling precise and instant ""cross-span"" collaboration capabilities. Through the integration of virtual and augmented reality, information is transformed into a ""visualized"" presentation, allowing users to intuitively understand and operate, thereby assisting enterprises in effective resource management, reducing waste, and helping industrial production lines lower carbon footprints. This, in turn, improves energy efficiency and achieves a more environmentally friendly production model.

The application scope covers various stages of industrial production, including machine equipment, factory premises, vocational training, remote collaboration, maintenance and operation, and business showcases. Through comprehensive cross-platform integration technology, it provides intelligent, efficient, and eco-friendly solutions.