展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

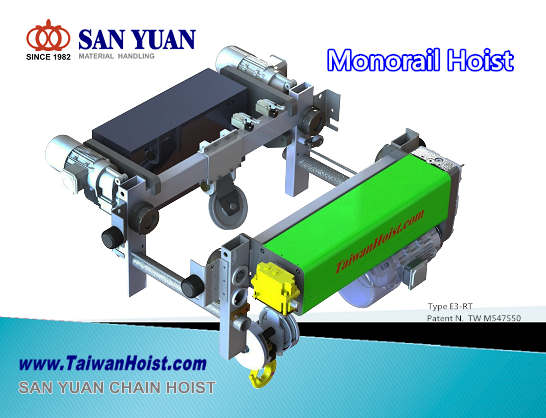

SUNG YANG MACHINERY CORPORATION

製品の説明 :

SAN YUAN Monorail Low Headroom wire rope hoist

●Hoisting Brake – disc brake having the braking torque >150%rated torque of motor .

●The brake is holden even if power failure - ensuring the load isalways stopped when the control button is released.

●Gears are smoothly operated for an oil bath lubrication and superior to a wear and abrasion resistance.

●Fine machining of the drum grooves minimizes wear on the rope, the return sheaves are resistance to wear.

EQP SERIES CO., LTD

製品の説明 :

Voltage Sensitivity: 10mV/(m/s²)±10%

Power Supply: DC15~36V

Constant Current: 0.5~10mA

Resonant Frequency: Approximately 40kHz

Frequency Response: 5~10kHz (±3dB)

Maximum Acceleration: 220m/s²

Shock Resistance: 49,000m/s²

Noise Level: Below 100μVRMS

Operating Temperature Range: -50~110℃

Detection Structure: Shear Type

Case Material: Titanium

Mass: Approximately 10g

JIN TAIRY ELECTRIC CO., LTD.

製品の説明 :

Intelligent Oil Mist Recovery Air Purifier-Function

1. Intelligent screen display function

(1) 7-inch touch-sensitive color LED display

(2) With Chinese and English language interchangeability

(3) With processing time count

(4) The service life of the filter bucket is displayed by LED lights (green, yellow, red) and the screen display, so you can know the status of the filter bucket in real time

(5) With failure record/maintenance notice

(6) With display of motor operating temperature and time

(7) Updateable with parameters

(8) Online program update (online version) (optional)

2. Optional

(1) WiFi communication module

(2) Open Modbus communication (Ethemet or WiFi) provides third-party integration

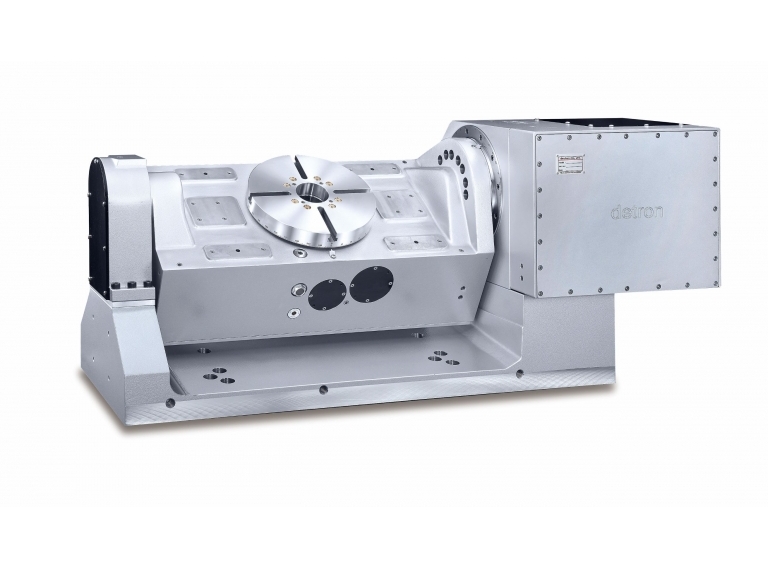

MATRIX PRECISION CO., LTD.

製品の説明 :

GHP-3540 applies the FANUC controller and high speed grinding spindle, through the in-house developed intelligent conversation window software, it can flexibly output the required tooth profile and grinding parameter. The machining workpieces include the involute gears and cycloidal gears, the high efficiency and high precision expressed from the product are equivalent to worldwide top brand's ones. GHP-3540 is your best choice.

MONGTEC PRECISION INC.

製品の説明 :

◎ The general spindle speed is only 6000-15000rpm, and the tool can be pushed up to 55000rpm through 15-70bar coolant pressure, saving 70% of cycle time

◎ Various interfaces can choose BT/HSK/ER/PCS/straight

◎ Tool can be changed by ATC

◎ Display processing tool speed with chip transmission

◎ Excellent run out within 0.003mm

YATAGHAN ENTERPRISE CO., LTD.

製品の説明 :

36W/40W is lightweight Single Function Ultrasonic Polisher with affordable prices so it totally fits the requirements of endusers.

The high micro vibration stroke frequency saves time to reach a quality result of polishing and finishing.

Their shaking is much smaller than Air Tools and it is perfect for objects that needs detailed polishing. Like precision molds, electronic molds, PCB boards, jewelry and so on.

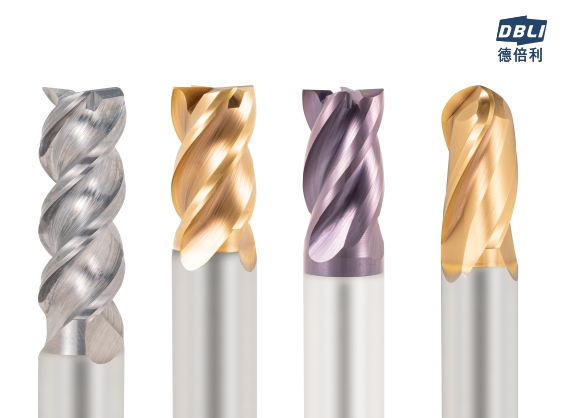

DEEP JET INDUSTRY CO., LTD.

製品の説明 :

1. Use in high speed machining and hard workpiece machining. It improves the quality and machining speed which is the best choice for precision processing.

◆Carbide Asymmetric Corner Radius End Mill (Steel)-Asymmetric helix angle 40º/42º and unequal flute design to effectively reduce the vibration rate and increase the tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 50/50.5/51 and unequal flute design to effectively reduce the vibration rate and increase the tool's stability. This makes the surface smoother.

◆Carbide Asymmetric End Mill (Steel)-Reinforced asymmetric 36º/38 º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.

◆Carbide Asymmetric End Mill (Aluminum)- Reinforced asymmetric 44.5º/45º/45.5º design with special grinding technique to reach better surface roughness. Avoid vibration problem during machining and increase tool's stability.