展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

LETS MEDIA CORPORATION

製品の説明 :

台灣模具暨製品總覽為模具公會跨年度會員名錄,每年固定八月出刊,內容刊載300家優質產品廣告及登錄500餘家會員廠商資訊,2023~24年將在20檔國內外模具相關展覽

大量發送書刊及USB電子書,被視為採購台灣模具及模具週邊製品的最佳搜尋範本。

ACROW MACHINERY MFG. CO., LTD.

製品の説明 :

Hydraulic Chucks / Angle Head Chucks / Boring Head / Toolholder / Collet / Fixture

GP MACHINERY CO., LTD.

製品の説明 :

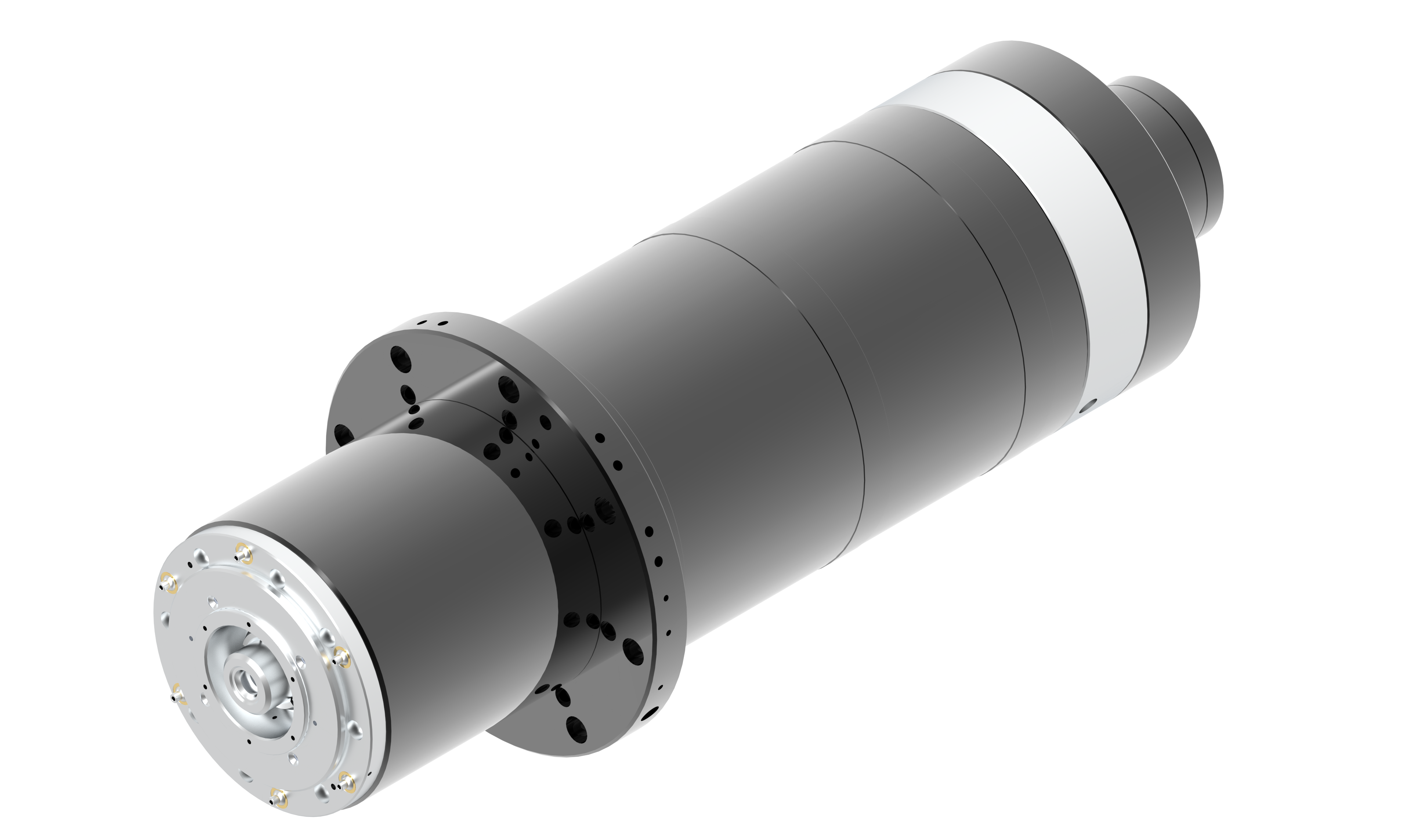

Built-In Spindle

◆ Lightweight design.

◆ After the mandrel is cryogenically treated, the heat variable is small and the machining accuracy is excellent.

◆ The internal cooling system adopts spiral circulation to achieve high-efficiency operation.

◆ The spindle adopts ceramic ball bearings from Europe to achieve optimal power and excellent rigidity.

◆ With standard accessories bearing temperature sensor PT-100.

TY UNIVERSE INDUSTRIAL CO., LTD.

製品の説明 :

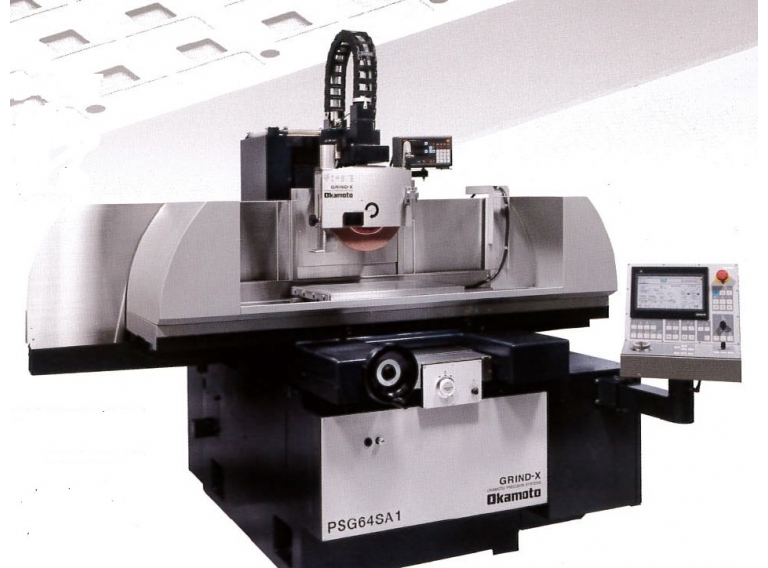

岡本工作機械<br />

平面磨床 PSG63SA1<br />

1.最小進給量0.1μm的高精度設定。<br />

2.水循環部分使用SUS。<br />

3.鞍座型機身設計,具有省空間的優勢。<br />

4.使用新式控制系統及新式操作盤,藉以提升操作性及概括管理切硝資訊。<br />

5.具高剛性、新觸控面板、熱變異少的機械造及具有自動修砂功能的高性能。

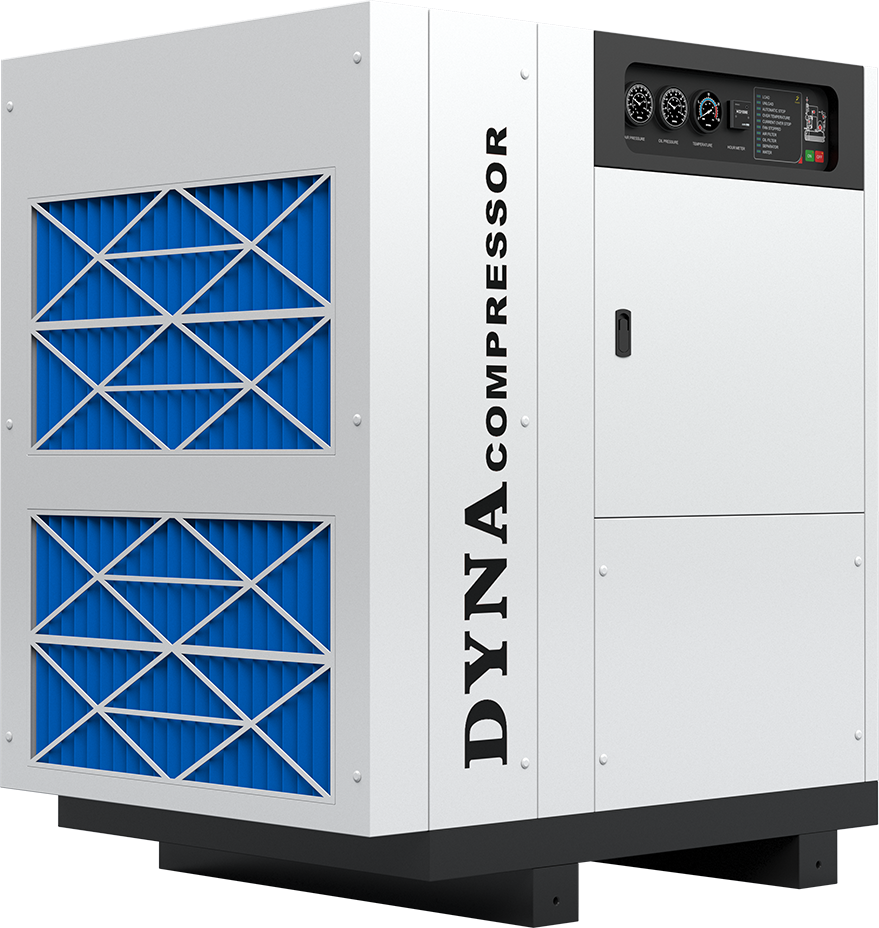

DYNA COMPRESSOR CO., LTD.

製品の説明 :

Air end compression system

100% imported from Germany. Inorder to ensure the quality ofoperation and stable air flow of the air compressor, we use Germanhigh-precision rotors with stableperformance, excellent quality, and more durablity.

Dyna Compressor With continuous R&D and renovation, our product is advance with times, our goal is to be the most competitive brand,

professional, exquisite, design that with enough flexibility and mobility to meet challenges of the market. Customized is our standard procedure. We grab every possible chance to provide new opportunity and vitality for

industrial reengineering. Under this rapidly changing, competitive era, the

only constant belief of ours is “quality is our strength”.

A Being Kou Tools Co., Ltd.

製品の説明 :

MicroCentric was founded in 1969. 50 years of advancing engineering and high-quality manufacturing has earned MicroCentric the reputation as the global leader in precision workholding technology. Each MicroCentric product is backed by superior design, the highest quality materials and precision workmanship for reliable, long term performance and unmatched accuracy.

MicroCentric is renowned for building workholding products of unmatched precision and accuracy. Most MicroCentric’s precision chucks have a standard repeating accuracy of .0001″ (0.002mm), and many models are accurate to within .00005″ (0.001mm).

CLAMPTEK ENTERPRISE CO., LTD.

製品の説明 :

*High supporting force

CSP-P/ CSP-K increases the holding force between the piston rod and the inner jacket to arise the higher supporting force.

*Coolant cleaning measures

In order to prevent the malfunction from the intrusion of high-pressure coolant and the cutting dust entering the internal structure, air can be cleaned at the breathing port when replacing the workpiece. Air cleaning requires a dedicated air circuit. (recommended cleaning pressure is 0.3 - 0.5MPa).

*Universal piping base

CSP-P/ CSP-K piping base is interchangeable, which can be installed with other low-pressure cylinders in the same specifications.

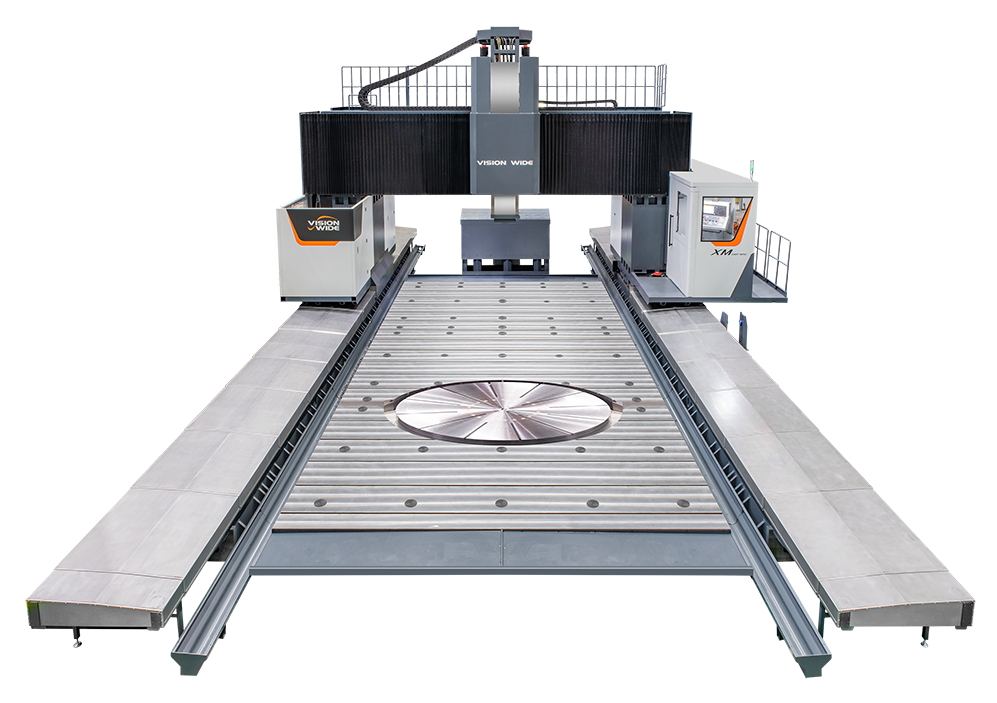

VISION WIDE TECH CO., LTD.

製品の説明 :

High Performance and Wide Application

XM series moving column machining center is a product developed for the machining needs of large-scale precision machinery, electric power, wind power, energy, petrochemical, transportation... and other equipment. It has:

Huge workpiece machining space: For precision machining of various types of structural parts, it can provide super large XYZ axis machining space.

• High-precise positioning: The high-standard geometric accuracy and positioning accuracy capabilities of the whole machine enable large-scale precision machining

• Heavy cutting capacity: Provide a variety of high-rated torque spindles to meet the processing and cutting capabilities of various materials.

• Fully automatic multi-face machining: This moving column machining center can be matched with various automatic attachment heads for high tangential speed mold surface machining and various types of precision parts complex angle machining, with excellent tool tip point error automatic correction function, and automatic additional head and tool exchange function, it can realize fully automatic machining performance.

• Milling and turning compound multitask: This moving column cnc milling machine can be equipped with a high-torque and high-speed vertical turning table to realize milling and turning compound automatic machining.

KO-YAN PRECISE MACHINERY CO.,LTD

製品の説明 :

GJ-400 series from COMIRK combines internal grinding and cylindrical grinding in a single machine. Multiple face grinding can be accomplished with one setup for the work-piece. This machine not only saves considerable amount on machine investment costs and labor costs, but it also features dramatically upgrade for better machining efficiency and machining accuracy.

Machine Features

-Various speed of spindles selection allows for the highest grinding efficiency

-Double wheel spindles exhibit high efficiency internal and external grinding

-Internal, external, end face and tapered face can all be ground in one process

-Highly rigid machine structure ensures the best possible stability during grinding

-X, Y, Z axes are all mounted with high precision linear guide-ways.

-This machine is equipped with a FANUC CNC controller

-Multi-face grinding requires only one setup for the work-piece.

-Non-circular grinding function is available (Optional)

-Fully enclosed splash-guard