展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

TORNG INDUSTRIAL CO., LTD.

製品の説明 :

* Vertical tool rest : Aluminum.

* Cast Iron Body.

* Dual purpose: Vertical & Horizontal use.

LNC TECHNOLOGY CO., LTD.

製品の説明 :

• 7” touch screen

‧EtherCAT protocol provides high flexibility of peripheral equipment connection control

• All-in-one design: pendant integrated with control unit

• IP65 waterproof and dustproof protection

• Magnetic back fixing bracket

• Electronic hand-wheel design to machine tuning, facilitate adjustment and program dry run

• Support multiple types of robots: Six-axis, Delta SCARA or customized special type robots.

• Axis control: six-axis(for robot itself) and additional three axes (for external accessories)

• Application: Polishing robot, spraying robot, welding robot, handling/palletizing robot

GUANDA INTERNATIONAL MACHINERY CO., LTD

製品の説明 :

An ultimate solution to making QR code tag for structural steel beam industry.

From band feeding, QR coding, digit stamping, cutting, and collecting, all processes done in one machine.

KING NICE TECH.CO., LTD.

製品の説明 :

▎Liquid filter purification, easy removal.

▎ Patented technology - easily correspond with liquid,water-soluble and Pure-oil Auto.

▎ Processing can easily recover swarf and sediment without stopping.

▎ The highest filtration accuracy can correspond to 5 nano.

▎ Solve the problem of long-term deposit on CNC water tanks such as iron chips,aluminum powder,fine sediment,etc.after machining.

▎ Widely used in metal cutting, aluminum machining,grinding process,engineering plastics, etc.

FOCUS CNC CO., LTD.

製品の説明 :

45 degree slant bed one piece casting the structure with low center of gravity, easy access and work-piece changeovers. Improved chip removal helps prevent thermal deformation. Powerful 4 stage spindle bear box provides 45kW horsepower available for large diameter work-piece and heavy duty cutting. Large through hole suits numerous bar sizes. Double row roller bearing increases stability and rigidity for heavy cutting.

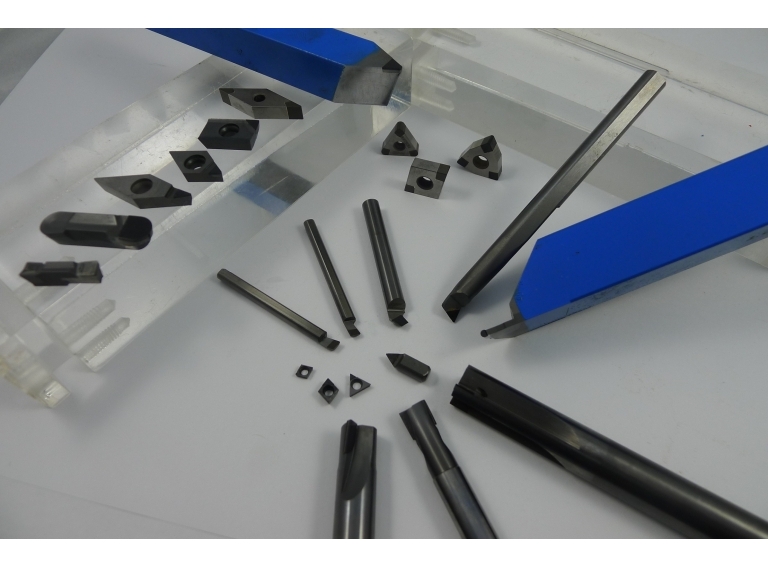

HWA CHERNG DIAMOND INDUSTRIAL CO., LTD.

製品の説明 :

華承鑽石生產鑽石刀具以長達18年之經驗. <br />

鑽石及氮化硼車刀可作為車削加工, 使加工面非常精且光滑如鏡. <br />

提高生產力並且取代研磨. <br />

YI HSIN TECHNOLOGIES CO., LTD.

製品の説明 :

JIHSENSE INDUSTRIAL37JS F200 TOOL HOLDER PULLING FORCE MEASURING DEVICEJS-F200 拉刀力計係結合本公司力量感測器及掌上顯示器而成之高精度拉刀力測試器,使用應變規為感測元件,變形量小,精度高。適用於 7/24 錐度刀把。一體式的設計,簡潔美觀,免除拉線的煩惱;顯示器使用 LCD 顯示螢幕,省電美觀,具高點保持、自動歸零功能,並可設定三種顯示單位,特別設計的省電線路及自動斷電功能,增長電池使用壽命。握把使用高強度鋁合金重量輕易於攜帶:JS F200 is a high-precision tool holder pulling force tester. It use the strain gauge for the sensing element, with small deformation and high precision. Applicable to 7/24 taper spindle. It integrated the load cell, signal processing unit and LCD display, to a compact measuring device. No connector and cable on it, simple and beautiful. Specially designed auto power off function, increase battery life.

HOLDING ELECTRIC CO., LTD.

製品の説明 :

Holding Magnetic tools honing edge machines can achieve the following effects in a short time.

1. Trim the chipped and sawn edges to remove burrs and burrs.

2. Achieving consistent rounding processing, making the blade smooth, smooth, and sharp, durable.

3. Improve the surface finish and surface roughness of the workpiece.

4. Increase tool life and reduce the probability of chipping. The measured value can increase the tool life by up to 65%.

FanRuan Software

製品の説明 :

FineBI is a self-service business intelligence tool that enables users to intuitively discover, analyze, and alert hidden issues within data through data analysis dashboards. It allows for timely response to business risks and identification of areas for growth. With FineBI, everyone can leverage data analysis to enhance business operations. FineBI assists enterprises in swiftly establishing a data analysis and business intelligence platform accessible to all members, enabling a comprehensive understanding and utilization of their data. This support aids in decision-making and enhances overall business performance.

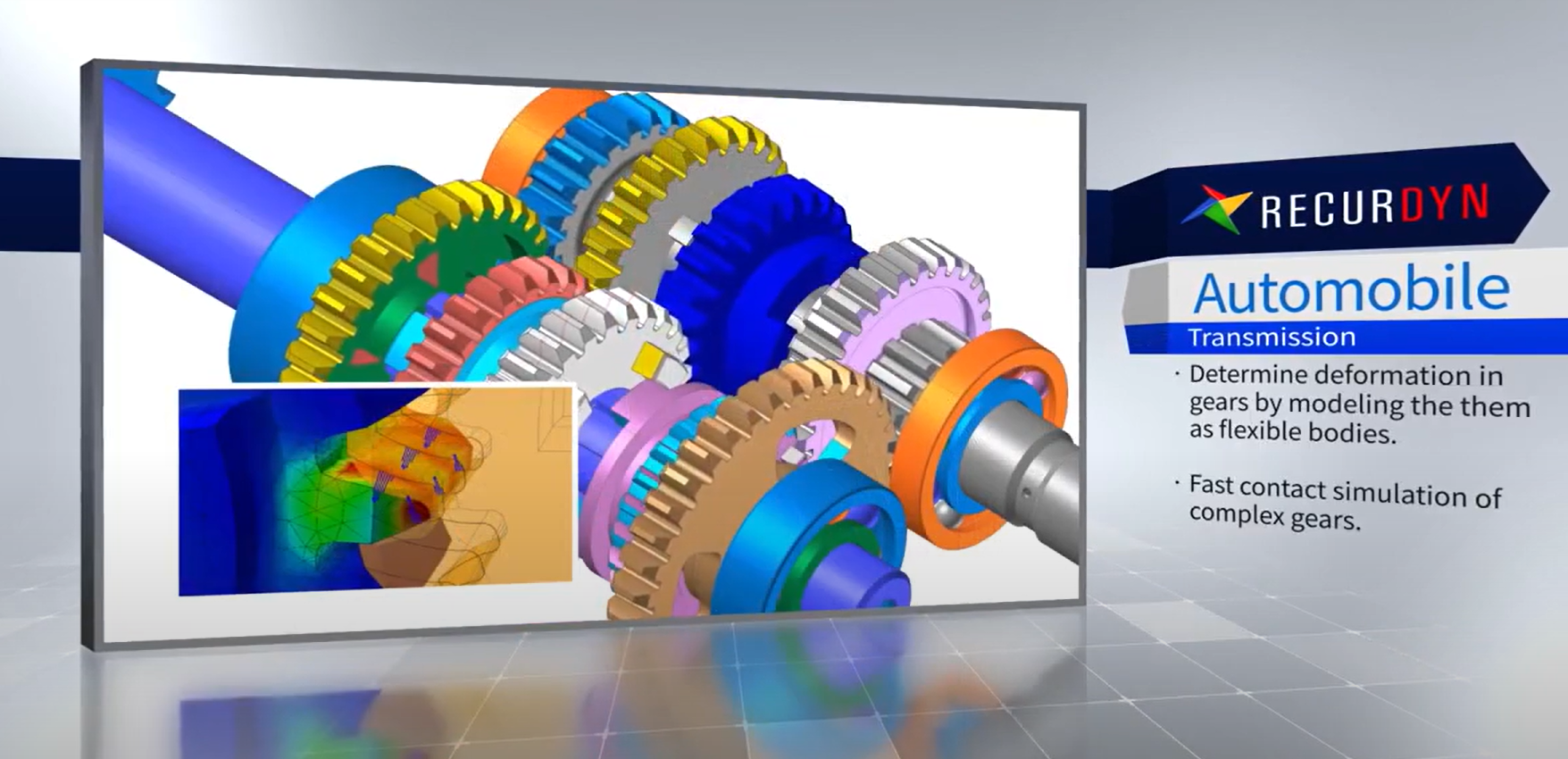

Taiwan Auto-Design Co.

製品の説明 :

RecurDyn is an interdisciplinary CAE (Computer-Aided Engineering) software based on Multi-Body Dynamics (MBD).

It provides fast and efficient solvers, an intuitive interface, and various libraries.

RecurDyn simulates both rigid and flexible body dynamics by combining traditional rigid MBD with cutting-edge

finite element technology for modeling flexible bodies. In addition to MFBD (Multi Flexible Body Dynamics), RecurDyn

also includes a tightly integrated controller design tool, design optimization, and durability and fatigue analysis.

RecurDyn also supports co-simulation with various other CAE software tools. It enables a seamless co-simulation

environment (Particleworks Interface) for coupled simulations with computational fluid dynamics solver, Particleworks,

allowing for detailed analysis of the interaction of fluids and multi-body systems.

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

XYZ axes travel: 500x400x185mm (20"x16"x7") inch

U axis travel: 300mm (12") inch

Z axis single travel: 400 mm (16") inch

Work table: 800x450 mm (31"x18") inch

Max. Workpiece: 1250x650x390 mm (49"x26"x15") inch

Max. Workpiece weight: 1400 kg

Max. Electrode weight: 185 kg

Machine net weight: 2100 kg

Oil level: 110-360 mm (4"-14") inch

Packing Size(LxWxH):2340x2320x2500 mm (92"x91"x98") inch

Work Table to platen:

1. Z axis single travel: 230-630 mm (9"x25") inch

2. UZ axis: 230-715 mm (9"x28") inch

Filter: 1

Paper filter:2

Capacity:550 Liters

Machine Features

> Windows CE controller

> A dialog window with picture description.

> Special repaired frames to quicken the maintenance speed.

> Close-loop design of digital feedback on three axes of the machine significantly increases positioning precision and ORBIT-CUT machining accuracy and efficiency.

> Simple operation interface.

> Common function keys are located on the operational panel for direct use.

> Hot key setting.

> ATC (automatic tool change) and C-axis 360° index can be installed; the process of coarse machining to ultra-fine machining can be completed at one time.

> Dialogue diagram provides various hole-expanding modes such as quick search of edge, centers and datum marks.

> Rich color graphic (the same resolution as a PC screen).

> Automatic multi-step machining (coarse, medium coarse, medium fine, fine, superfine)—up to 10 steps.

> Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to find.

> Automatic origin search and multi-point coordinate memory capability.

> 1/2 design capability, ARC automatic discharge waveform detection and automatic adjustment.

> Automatic center position detection, automatic compensation, search of hole center and deepest point; fixed hole machining (cyclic mode, independent mode), which is suitable for different machining conditions; Radial, circular, square, linear (vector), coning, 45° hole-expanding machining.

> Three-axis beeline, two-axis arc, three-axis helix.

> Chinese/English versions interface, metric/British system switch and Z-axis quick up, quick down, slow up and slow down capability.

> Lateral machining, three axes, six directions (plane rotation).

> All alarms describe the source, date and exact time of problem occurrence.

> Optical scale is applied for close-loop position control, enabling extreme position for machining.

> Automatic editing—settings can be done according to type of material, work piece size, machining depth, one side die clearance, final current and rate of electrode wear.

> CNC models possess conventional capability of consistent level of energy discharge, achieving stable and rapid machining and smooth high quality on machining surface while the rate of electrode wear is still low.

> Monitor page indicates machining path and orbital pattern in use.