展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

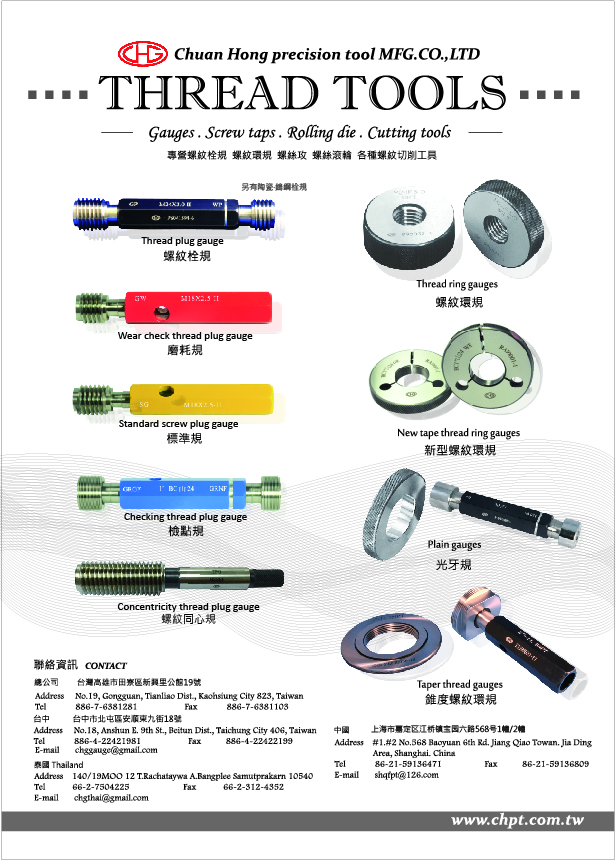

CHUAN HONG PRECISION TOOL MFG. CO., LTD.

製品の説明 :

<<栓規‧螺紋栓規>>

"栓規":專門檢查產品是否符合標準之量規。

"螺紋栓規":專門量測產品(母螺紋)是否符合廠內、國家或國際標準。

<<錐度栓規‧錐度螺紋栓規>>

"錐度栓規":專門檢查錐度產品(管用)是否符合標準之量規。

"錐度螺紋栓規":專門量測錐度產品(母螺紋)是否符合廠內、國家或國際標準。

<<環規‧螺紋環規>>

"環規":專門檢查產品是否符合標準之量規。

"螺紋環規":專門量測產品(公螺紋)是否符合廠內、國家或國際標準。

<<錐度栓規‧錐度螺紋栓規>>

"錐度栓規":專門檢查錐度產品(管用)是否符合標準之量規。

"錐度螺紋栓規":專門量測錐度產品(母螺紋)是否符合廠內、國家或國際標準。

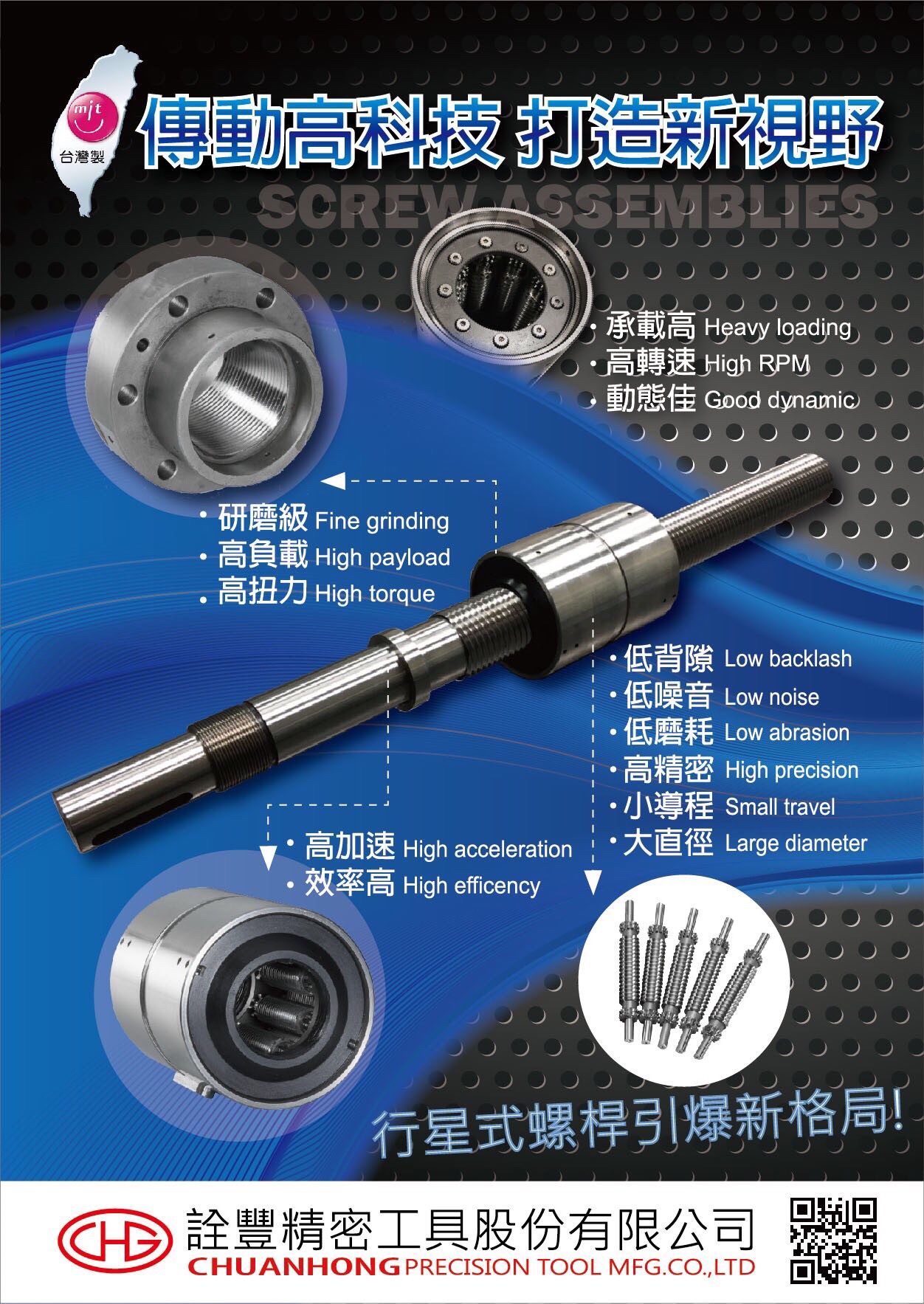

TORNG INDUSTRIAL CO., LTD.

製品の説明 :

* To provide cooling, lubrication and chips removal functions simultaneously.

* It's designed for machinability, machining speed and extend the tool life.

* To save machining time and reduce machining cost.

* To ensure high quality of machining and cutting performance.

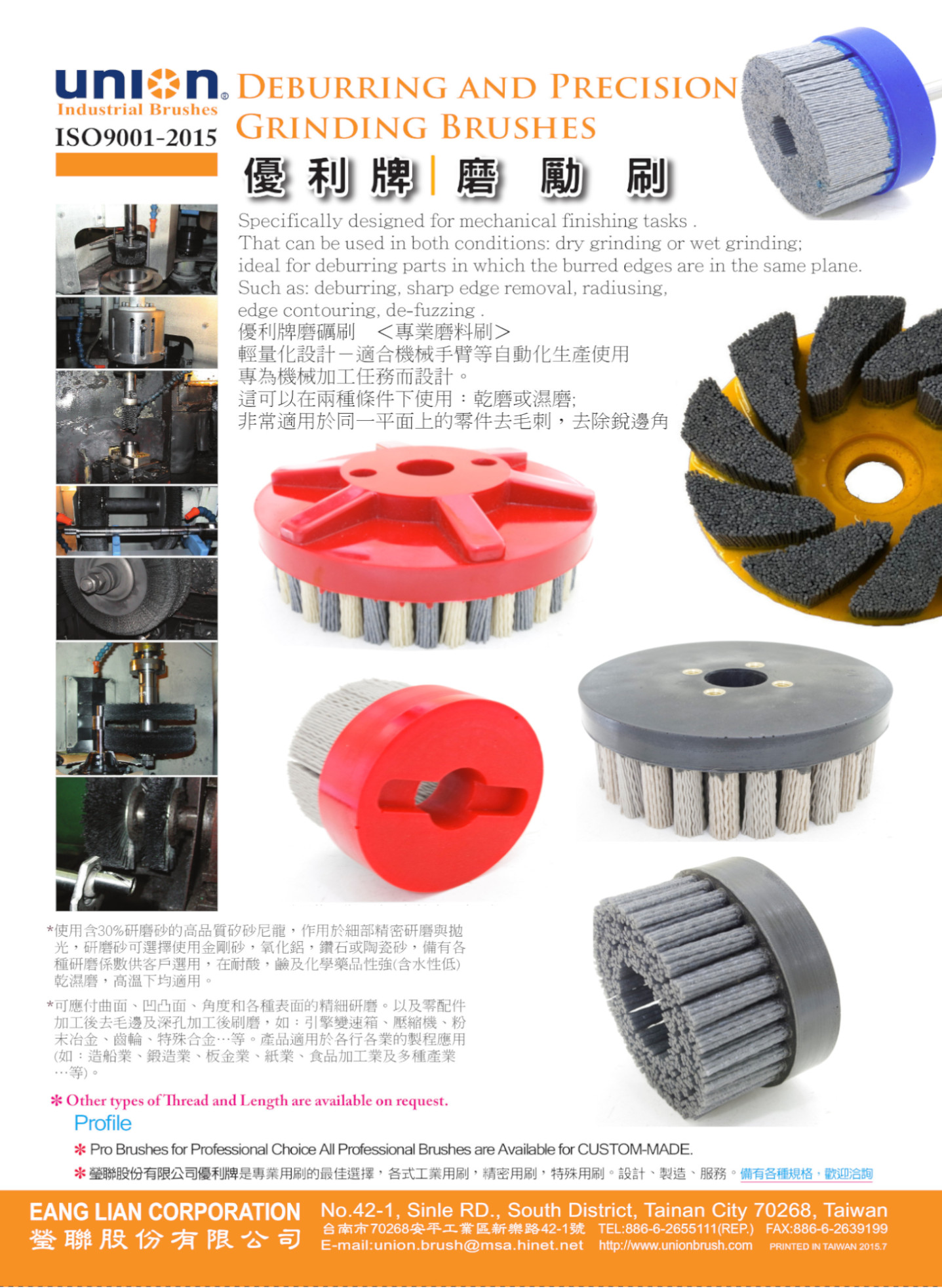

EANG LIAN CORPORATION

製品の説明 :

Professional Abrasive Brushes-Specifically designed for mechanical finishing tasks .

Specifically designed for mechanical finishing tasks .

That can be used in both conditions: dry grinding or wet grinding;

ideal for deburring parts in which the burred edges are in the same plane. Such as: deburring, sharp edge removal, radiusing,

edge contouring, de-fuzzing .

HO CHEN MACHINERY & ELECTRIC IND. CO., LTD.

製品の説明 :

XYZ axes travel: 600x400x400mm (23.62"x15.74"x15.74")

W axis travel: 450mm (17.71")

Work table: 650x450mm(25.59"x17.71")

Max. Workpiece: 900x500x300mm(35.43"x19.68"x11.81")

Max. Workpiece weight: 700kg

Distance from table to guide plate:25~425mm(0.98"x16.73")

Machine dimensions: 1580x1250x2740(62.2"x49.21"x107.87")

Machine net weight: 1200kg

Electrode diameter: 0.2~3.0mm

Dielectric fluid: pure water ( dielectric oil for 0.2mm or below)

Filtration: Paper filter

Controlling axes XYZW

Monitor: 15” LCD screen

Input/output unit: LAN/USB

Min. Setting Unit: 0.001mm

Min. Moving Unit: 0.001mm

Graphical display: 2D

Machine Features

1. This system utilizes Windows CE controller.

2. Able to store data through USB and internet.

3. Dialogue window, along with picture description functions.

4. Touchscreen type interface.

5. Special repaired frames to quicken the maintenance speed.

6. Close-Loop design of digital feedback on three axis of the machine, significantly increases positioning accuracy.

7. Possessing good and simple operation interfaces

Common function keys are located on the operation panel for direct use, hot key function on screen for quick access.

8. ATC (automatic tool changer) and AGC(automatic guide chnger) can be installed

9. Unlimited number of machining conditions can be saved as machining archives. Each set of machining conditions can be edited, modified or stored. They are easy to edit and easy to search.

10. Automatic origin search and multi-point coordinate memory capability.

11. Chinese/English versions, Metric/British system switch and quick up, quick down, and slow up and slow down capabilities, resolution can reach 1um.

12. All alarms describe the source, data and exact time of problem occurrence.

13. Able to proceed standard GM code and extra GM code

14. Able to proceed DXF file transfer to position coordinate function

15. AB axis rotate table can be installed

16. Position simulation and work route can be displayed

17. During discharge change new electrode can automatically compensate depth

18. Backlash point automatic compensate function

19. Able to do single hole drilling, multiple hole drilling and multi thickness drilling

20. Blindhole drilling function, any depth can be set

21. Initial current can set to reduced value, which can prevent workjob surface damage

22. Initial polarity reverse function, can prevent uneven electrode caused efficiency decrease

23. Six axis linear interoperate accelerate speed movement

24. Input, output, various of machine status real time display system

25. Discharge program and parameter conversion function

Accessories

《 Standard Accessories for High-speed Drilling CNC EDM 》

Tool Box*1

Brass Electrode 1.0mm*10

Electrode Guide 1.0mm*1

Standard Chuck*1

Foot Pads*1 set

Filter*1

Rubber Seal*10

Halogen Work Lamp*1

Flushing Unit*1 set

《 Optional Accessories for High-speed Drilling CNC EDM 》

ATC

Electrode Guide(Other diameters)

Brass Electrode(Other diameters)

ER Type Chuck for electrodes up to 6mm

Submerged Work Tank

75Amp Power upgrade

Filtration System with Resin Bottle

A,B Axes

Automatic guide changer 3/6

TAIWAN 3AXLE TECHNOLOGY CO., LTD

製品の説明 :

Created to meet the demands of modern welding, MAXWELD combines a stylish appearance with outstanding performance. Focused on space optimization, it makes your workspace more spacious and efficient. MAXWELD is the world's first model to adopt a large-area airflow design, specifically designed for high-temperature environments within factory facilities. This unique airflow design ensures that the equipment maintains effective cooling even under high-temperature conditions. Additionally, MAXWELD comes equipped with dust-proof cotton to effectively prevent dust from entering, ensuring the stable operation and extended lifespan of the equipment.

JAR HON MACHINERY CO., LTD.

製品の説明 :

1.Attached with multi head which can drill many parts at the same time in order to enhance efficiency.

2.Design a complete unit of multi head, guiding hole plate and jig in order to have high accuracy.

3.Suitable for reaming, drilling and chamfering.

4.Optional functions: "Auto. discharging chips" and "Auto. breaking chips".