展示テーマ

デジタルトランスフォーメーション

グリーントランスフォーメーション

CAPTAIN SCIENCE CORPORATION

製品の説明 :

Provides a clear view of the production processes under toughest milling conditions.The spinning window is an approved system to keep inspection window clean and thus to ensure continuous control of work

flow. Rotoclear S3 is suitable for all kinds of metal cutting machines such as turning centers, milling machines, including machining centers and test stands.

CHUAN TAI HYDRAULIC MACHINERY CO., LTD.

製品の説明 :

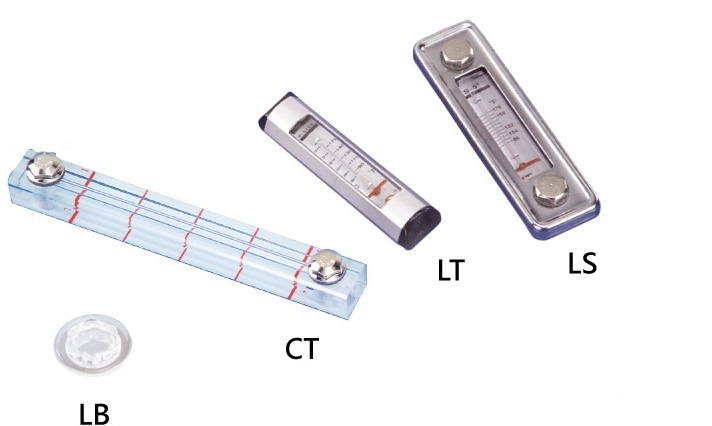

The oil level gauge is made of special materials by injection molding, which has anti-impact characteristics and is not prone to cracking during installation.

Special specifications can be customized

YATAGHAN ENTERPRISE CO., LTD.

製品の説明 :

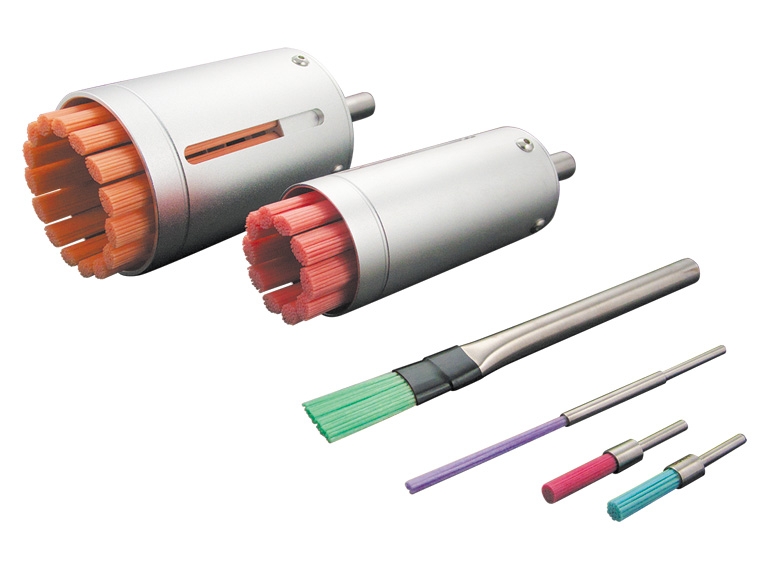

Cristone Bristle Brush consists of Crystal Fiber Stones. The cutting performance, tool life and flexibility is superior than any other polishing stones or brushes.

It can efficiently remove the roughness of the surface but prevent excessive shaving.

For different grinding purposes and processing ways, we provide a wide selection of variable types for solutions so you can greatly boost your efficiency of grinding or polishing.

LIS AUTOMATIC CONTROLLED CO., LTD.

製品の説明 :

The PJ-20S is a fixed volume medium pressure system without tank designed. Suitable for a general manufacturing environment, designed for Swiss lathes.

-modular PCB, easy to maintenance

-intuitive control panel, easy to operation

-3 sets of M code output

-compact size, saving space

SESAME MOTOR CORP.

製品の説明 :

Sesame gear motors are parallel shaft induction geared motors offering output 100W (1/8HP) - 2.2kW (3HP), torque range 1.76 Nm - 1166 Nm. Wide range of application including chip conveyors. Power-off brake and various AC power supply options.

CNC-TAKANG CO., LTD.

製品の説明 :

主軸低轉速、高扭矩,四段自動變速,適合重切削之零件加工。<br />

一體成型3山形床身,結構高剛性。<br />

<br />

強力型主軸箱,齒輪熱處理硬化、經高精密研磨處理,適合重切削與精密加工。<br />

4段變速系統,低速高扭矩輸出。<br />

9轉時即提供全馬力輸出。<br />

<br />

高強度床身一體成型,採用高張力米漢娜鑄鐵,經熱處理及研磨加工,硬度HS70度以上<br />

各滑動面皆貼上滑摩樹脂(Turcite B),配合基準研磨面,經手工刮花加工,提供精密的移動與定位精度。<br />

X軸工字軌橫向滑板、Z軸三”V”型滑軌,高強度高剛性設計<br />

全手工鏟花<br />

主軸箱、刀塔、尾座、導螺杆軸承座、床鞍、滑台皆手工鏟花,均衡的接觸面提供高加工精度以及高剛性重切削,有效提供產能以及穩定的產品品質。<br />

<br />

高強度尾座本體,回轉式尾座心軸。<br />

回轉式尾座心軸設計與CNC車床主軸相同,剛性高、適合重負荷與高精密度加工。<br />

GSA TECHNOLOGY CO., LTD.

製品の説明 :

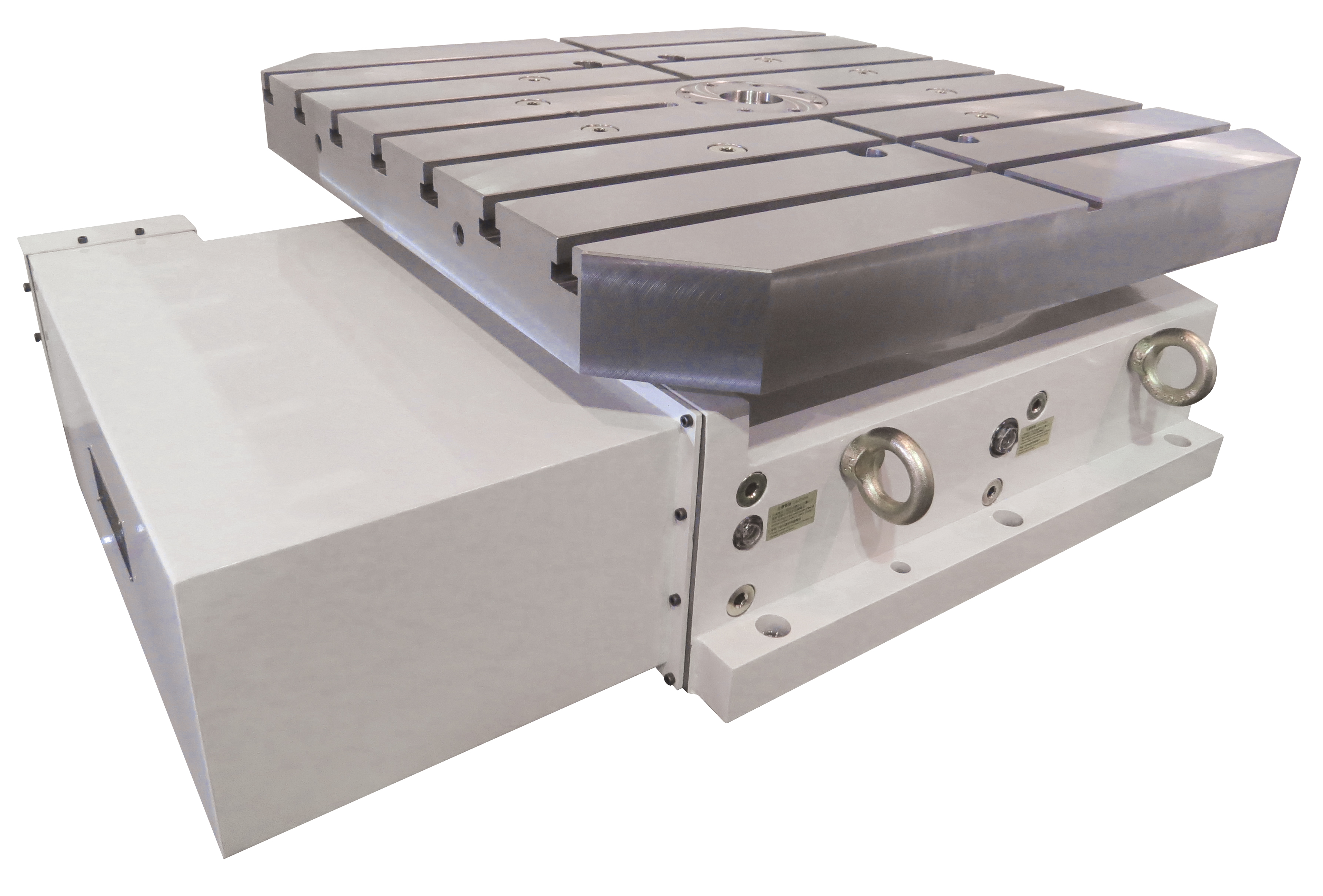

Suitable for Horizontal Machining Center,floor type boring machine。

High Accuracy,Adapting a special anti-wearing alloy of bronze/nickel double-lead worm wheel and hardened steel worm scrrew ensure long term indexing accuracy。

Table size from size 400mm to 2500mm or manufactured manufactured according to customer's designing and interface of machine Saddle。

Hydraulic Clamping,high rigid brake structure for heavy cutting。

Build-in hydraulic ports system suitable for Special Machine of Horizontal machining Center and Automobile/Motorbike Industrial。

DAH LIH MACHINERY INDUSTRY CO., LTD.

製品の説明 :

T型結構床台設計。<br />

X, Y, Z軸滑軌均採用鑄鐵批覆合金鋼方式一體鑄造成型,以提昇硬度、耐磨性、吸振性及防鏽性,以重切削能力為訴求。<br />

三軸皆採用預拉式滾柱導螺桿,可減少熱變形,提高定位精度。<br />

齒輪傳動,有二檔變檔功能,在302rpm時即可達到全馬力輸出。<br />

主軸及傳動齒輪採強製冷卻,可降低溫度,提申精度。<br />

主軸頭部與立柱滑道面為8面接觸,以提高剛性,在重切削時獲得最高的穩定性。<br />

主軸頭部為左右兩側對稱設計,可將溫度產生的熱變形降至最低的程度。<br />

穿梭式自動交換工作台,腳踏迴轉裝置。<br />

油壓系統,刀臂夾持自動刀具交換裝置(A.T.C),鍊式雙向迴轉刀盤結構,就近選刀。<br />

浴池式自動交換工作台(6 A.P.C)。<br />

<br />

TAIWAN MORE-CASH VILLAGE CORP.

製品の説明 :

1.Convenient Design

X, Y axis workable professional structure enhanced high-

performance cutting accuracy.

2.Cutting Capacity

Cutting diameter: Ø3~16mm;

Cutting length of work-piece end: 15mmL/max;

3.Patented Radius cutting by Dual-motor driver

The hardened treatment steel is controlled well in virtue of

natural dissipation characteristic, cutting time is greatly

shortened as the work-piece is simultaneously rotated while

cutting.

4.Quick-Work-Changing System

The work-piece is quickly exchanged with prime quality 3-Jaw

chuck system.

5.Cooling System

Dry cooling is able to connect with various pressurized air and

vacuum cleaner achieved perfect cooling effect.

6.Cutting Disc

SD#100 for Carbide, CBN#100 for HSS

7.Optional Grinding Wheel For GS-13 GS-13

SD#100 thickness 5mm, 10mm for Carbide, CBN#100

thickness 5mm, 10mm for HSS

A.Carbide end mill cutting efficiency on GS-13

■ Ø 10mm 4 flute carbide end mill is cut by SD#100 cutting

disc takes 55 seconds.

■ Ø 16mm 4 flute carbide end mill is cut by SD#100 cutting

disc takes 100 seconds.

B.HSS end mill cutting efficiency on GS-13

■ Ø 10mm 4 flute HSS end mill is cut by E60WA cutting disc

takes 60 seconds.

■ Ø 16mm 4 flute HSS end mill is cut by E60WA cutting disc

takes 110 seconds.